Liebherr LTM 1200-5.1 User Manual

Page 2

PN 1200-5.1_D-GB/F/I/ESP/RUS 03.07.2007 10:09 Uhr Seite 2

Probedruck

C

M

Y

CM

MY

CY CMY

K

11

2

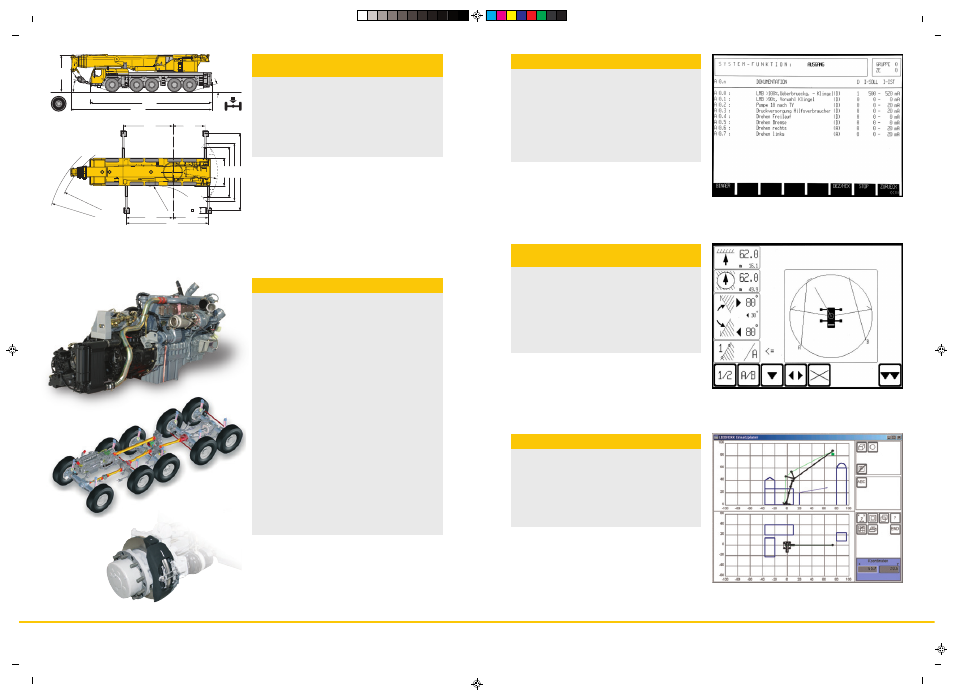

LTM 1200-5.1

LTM 1200-5.1

4000

13298

15282

60

3865

5034

8899

3483

5396

R = 5450

R = 11010

R = 11850

5500

6230

8300

R = 4850

3000

20°

17°

12 t

12 t

12 t

12 t

12 t

16.00 R 25

Compact, maneuverable and

weight-optimized

The LICCON test system

• The test system assists the servicing personnel in quickly

localizing failures of the crane sensory system without the

need of measuring instruments

• The service starts on the display screen, troubleshooting

becomes a matter of minutes

• Occurring errors are indicated by error codes and error

descriptions on the display screen

• Convenient interactive functios permit the observation of all

inputs and outputs of the entire system by different

representations on the display screen even during crane

operation. It equally visualizes the allocation of the individual

sensors and actuators of the system and their functions

The LICCON work area

limitation system

• It relieves the crane operator, especially in situations where

the handling of loads requires his full attention, by controlling

the work area limits. Work areas can be restricted by buildings,

bridges, roofs, high-tension power lines, pipe lines or adjacent

cranes. The automatic work area limitation system (optional),

can easily be programmed. Four different limitation functions

are practicable:

• Height limitation of the pulley head

• Radius limitation

• Slewing angle limitation

• Limitation of edges

The LICCON work planner

• The LICCON work planner consists of a software program

on CD for planning, simulation and documentation of crane

applications on the display screen (optional)

• The 2D planner program enables the drawing of buildings,

to write texts and to represent a crane model true to scale

including the entire motions within a fictional

construction site

• The work planner permits the preparation of more transparent

offers, facilitates the briefing of crane operators and can be

run on a Laptop at the construction site

• Powerful, 6-cylinder Liebherr turbo-charged Diesel engine

type D846 A7, 370 kW/503 h.p, exhaust gas emissions

correspond to the directives 97/68/EG stage 3 and EPA/CARB

Tier 3, robust and reliable, modern, electronically controlled

engine management

• ZF power shift gear with automated control system AS-

TRONIC. ZF intarder fitted directly to the gear unit, 12 forward

and 2 reverse gears, automated control, reduced fuel

consumption due to a great number of gears

• 2-step, robust transfer case with lockable transfer differential,

creeping speed 0.78 km/h

• Drive 10 x 6, axles 2, 4 and 5 driven

• Drive 10 x 8 (optional), axles 2, 4 and 5 driven,

axle 1 activatable for off-road displacement

• Weight-optimized, robust axles of minor maintenance, perfect

track keeping and lateral stability due to special arrangement

of the steering knuckles, steel- and rubber mounted

• Maintenance-free cardan shafts; easy and quick fitting due

to 70° diagonal toothing

• Hydropneumatic suspension "Niveaumatik",

program-controlled for "setting crane on outriggers",

"crane displacement with equipment" and for

"road displacement of the crane",

suspension travel +150/-150 mm

• Lateral force released and maintenance-free suspension

rams, protected against damage by synthetic pipes

• Sustained-action brakes:

Engine brake as exhaust retarder with Liebherr additional

brake system (ZBS), Intarder on gear, Telma-type eddy

current brake (optional)

• Service brake:

All axles fitted with air disc brakes, high braking performance,

long maintenance intervals, rapid-change brake linings

Modern drive concept

• Overall length 15.28 m, carrier length 13.3 m

• Large overhang angles of up to 20°

• Smallest turning radius of 11.01 m with all-wheel steering

• Rear counterweight radius only 4.85 m

• 60 t total weight incl. drive 10 x 8, tyre size 16, hook block

31.2 t (axle load 5 x 12 t)

• 3 optional tyre sizes

14.00 R 25 carrier width 3 m

16.00 R 25 carrier width 3 m

20.5 R 25 carrier width 3.1 m