Liebherr L 556 User Manual

Page 6

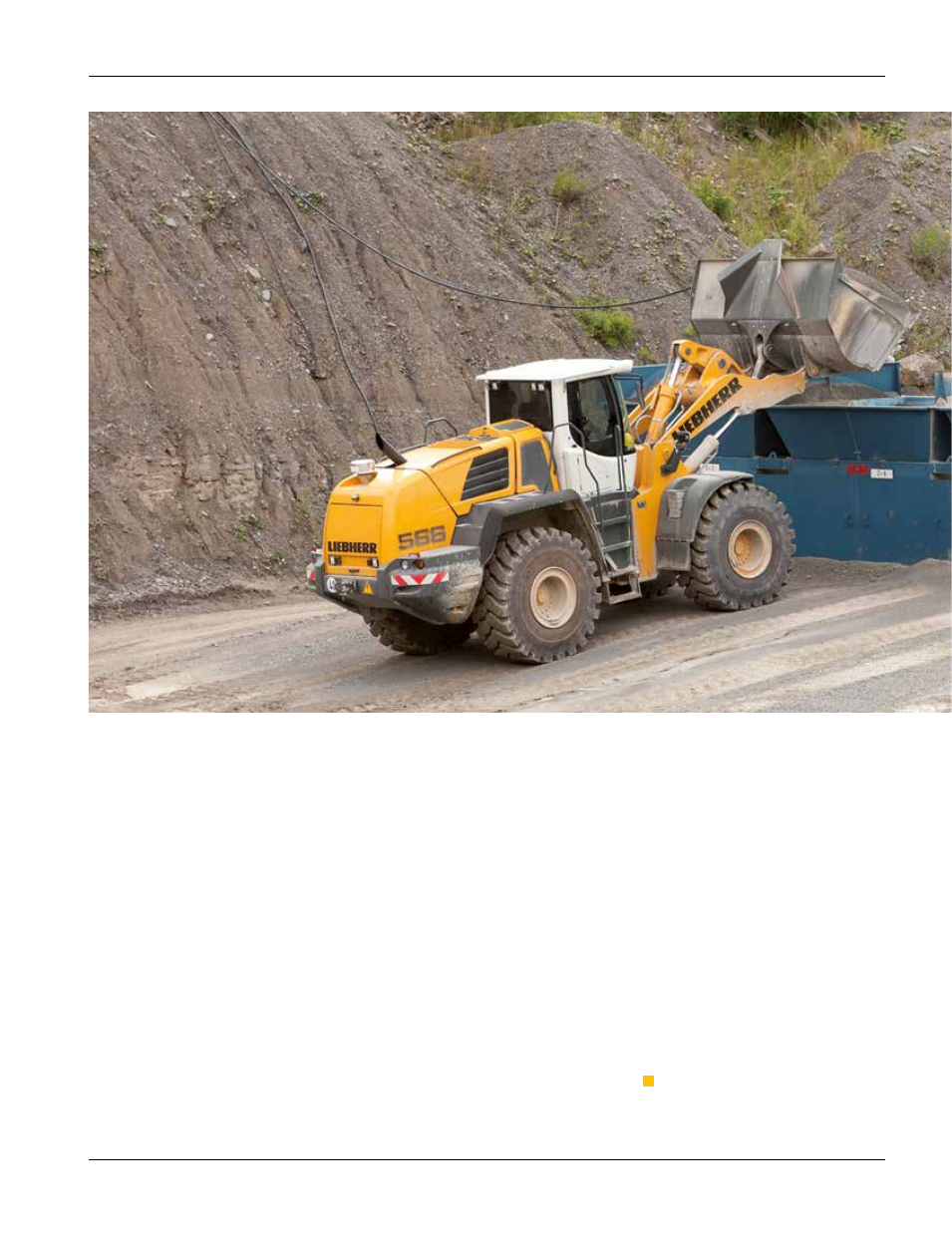

6 // Quarrying

in operations,” explains Beckers. “Fuel consumption and material

movement have been recorded and compared. This has enabled

us to obtain figures for fuel consumption per ton of material

quarried. With Liebherr machines, we can save 1.1 to 1.3 up to

sometimes even 1.6 gallons of diesel per hour. At 15,000

operating hours per year that makes several thousand US $.”

“ Liebherr machines allow us to save

1.1 to 1.3, sometimes even 1.6 gallons

of diesel per hour.”

Wolfgang Beckers, chief representative and regional manager

Mineral Baustoff GmbH for the German state of Thuringia.

Six-chamber blender: Customers order the grade they need when they arrive at the quarry, are given a recipe card and collect their gravel.

Fuel consumption is not the only criterion that is taken into

account for procurements. Service also plays an important role

as it has a decisive influence on machine availability. “Machines

that are not running immediately run up immense losses. That’s

something we can’t afford, and that’s why we use Liebherr

machines,” continues Beckers. “With the Nagel Group, we have

a truly competent and reliable service partner. Whenever we have

a technical question, we always get an answer straight away.”

Despite the fact that operations are heavily trimmed towards

efficiency, expense is not spared on the machines themselves.

“Our drivers work on the machines for up to 10 hours and must

be in top form at all times. That means they get the equipment

they need to make work easier. Comfort seats, climate control

and auxiliary heating, for example, are features on all our machines,”

says Beckers. “This makes work easier and, not least of all, it

is a question of safety.”

Feature: Mineral Baustoff GmbH