10 expert tips for long undercarriage service life, What is undercarriage wear – Liebherr L 556 User Manual

Page 14

14 // Quarrying

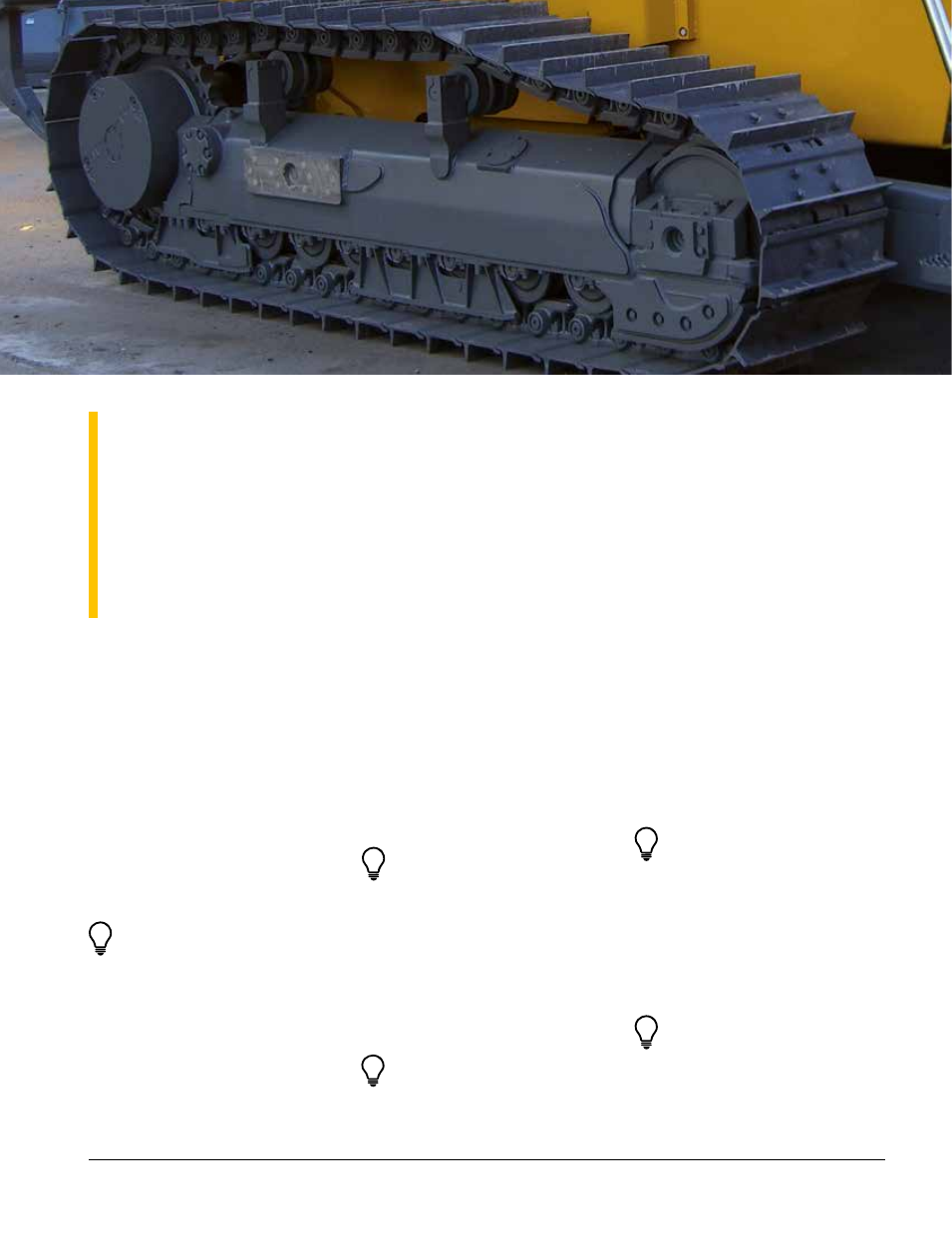

Guide wheel, track rollers

and carrier rollers

Guide wheels and rollers tension and guide

the chain, also transversely. Wear occurs

on the running surfaces and at the side

walls.

Track shoes

The webs and the track shoes themselves

wear over the course of time, especially

on hard ground such as rocks.

Chain bushings

On an oil-lubricated chain, the bushing

moves relative to the sprocket. This causes

wear at the bushing and the teeth.

Rotating bushing chains roll freely from the

sprocket, reducing wear on the bushing

and the sprocket. Because of their form,

rotating bushing chains are only of limited

suita bility for tough operations where

impact stress occurs.

Sprocket

Once the sprocket has become completely

worn, teeth could break and the chain

could jump. An excessively worn sprocket

also increases wear on the bushings many

times over. For this reason, great attention

should be paid to sprocket wear.

Chain links

The chain links run over the guide

wheel, carrier rollers and track rollers.

Wear occurs on the contact areas. This

often occurs in the form of wave wear.

10 expert tips for long

undercarriage service life

Regular servicing and the right way of working have a great influence on the service life of the undercarriage.

On construction machines with chains, wear can occur in the chain bushings, sprockets, chain links, guide wheels,

track rollers, carrier rollers and on the track shoes. There are several different ways to prolong the service

life of the undercarriage and to reduce costs related to the undercarriage.

Tip 1:

On oillubricated chains, the bushing

can still be used if it is turned around 180°

in good time (with a wear level of 70 to 80 %). The

actual savings depend on the labor costs incurred.

What is undercarriage wear?

Tip 2: As a rule of thumb, the sprocket seg-

ments must not meet tooth tip to tooth tip. At

least a narrow web must be visible. Details of this can

be found in the operating handbook for the machine.

Tip 4:

It is especially important for the

under carriage to be cleaned in the winter. This

will prevent the carrier rollers in particular from sticking.

At the same time, cleaning will lengthen the service life.

Tip 5:

As an alternative to track shoes of

standard quality, Liebherr also offers special

track shoes that have more wearing material for high-

wear operations. Examples of such special track shoes

are “ES Extreme Service” or “SESS Super Extreme

Service Shoes.”

Tip 3:

If vibrations occur when the machine

is in operation, this might be caused by wave

wear on the chain links.