Liebherr L 556 User Manual

Page 40

40 // Quarrying

It all started in 1934, when Joe Swap, the father of todays

managing directors David and Lewis Swap, shoveled river stone

from a river at the back of his dairy farm in Te Poi in the central

North Island of New Zealand. He put the material onto a 1930s

Ford truck and delivered the aggregate to local building sites and

farms. This was the starting point of his commercial activities.

Today, almost 80 years later, the company is one of the top

aggregates producers and a leading dairy stock food supplement

distributor in New Zealand. The company has regularly added

new business areas as opportunities have arisen. Many rural

customer relationships that started in the 1930s are still on-going

under the direction of Joe’s sons David and Lewis.

Besides them, the fourth generation has already started working

for the company. Joseph, who is Lewis’s eldest grandchild, is

already very active in the family-owned business. “When you’re

part of a fourth generation business it’s in your blood,” Joseph

Carter says. The family members are always on the go, either to

one of their ten aggregate quarries, four stockfood storage

facilities or six agricultural farms. Next to quarrying, stockfeed

and bulk storage they are also active in the contracting and heavy

haulage business – supported by their 380 employees.

Fuel economy: Keeping the environment green

“New Zealand is fortunate to have a clean green environment and

we want to keep it that way,” Lewis Swap says. “We work in an

industry that is important to New Zealand’s economy but could

be seen as environmentally challenging. We give special attention

to managing our environmental impact. Fuel economy is the first

step to do so.”

Nevertheless, powerful machines are needed to cope with the

heavy loads as in the quarry business. Over 2.2 million tons of

material is supplied from the ten aggregate quarries per year.

Thousands of tons of crushed aggregates have to be handled

by the company’s wheel loaders per year. Five large Liebherr

wheel loaders are operating in the company, three L 586 and

two L 556. The big machines are mainly used for bulk material

handling and are equipped with L 5 tires. For general works,

forestry and maintenance, the L 556 is used. All the machines

are operating fifteen hours a day without a break.

“We bought our first Liebherr machines three years ago. In 2013

we bought another L 556 and an L 586. The machines turned

out to be satisfying in terms of capacity and economy,” Lewis

Swap says. “What is especially striking is the L 586. Although

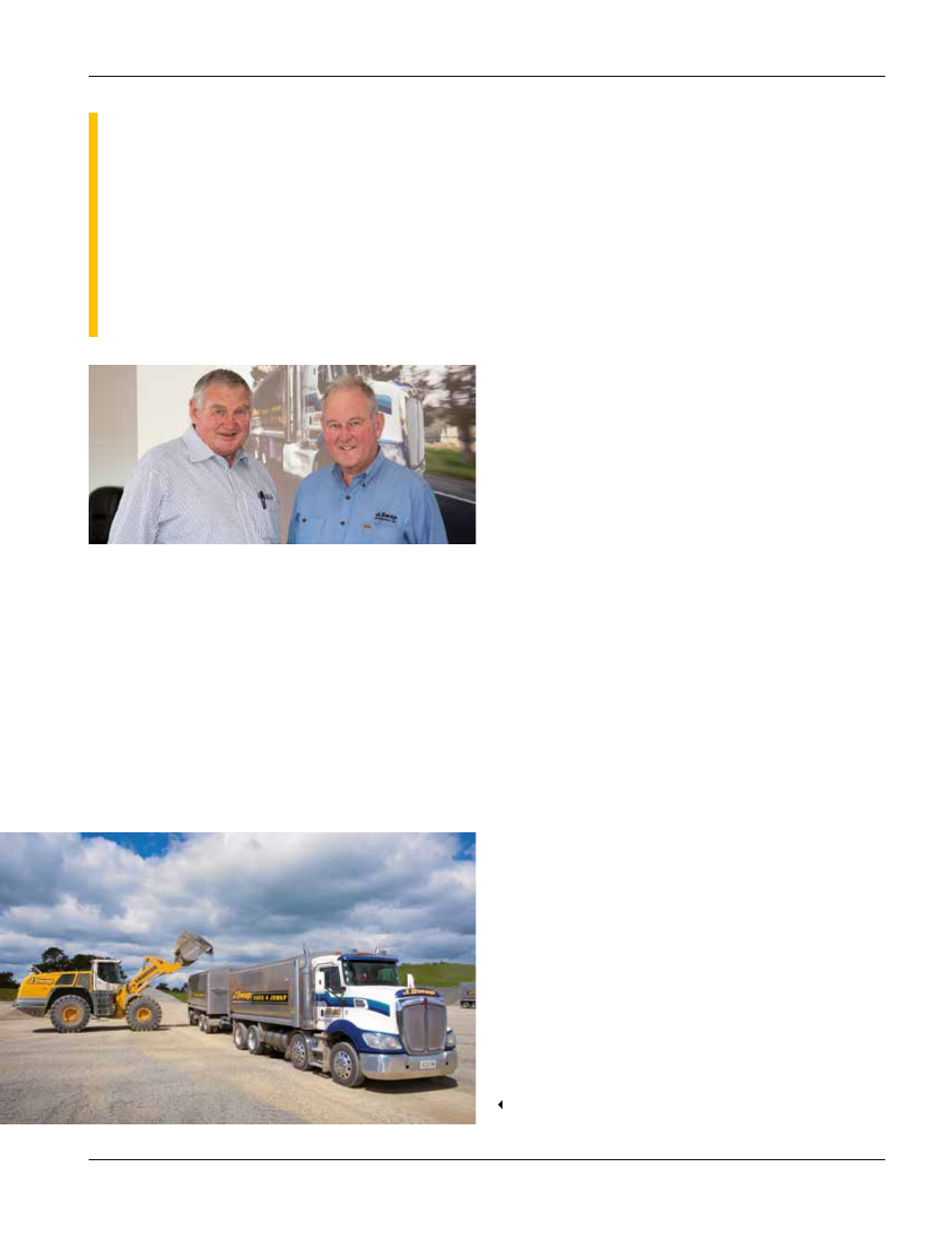

David and Lewis Swap, managing directors.

Capacity and economy were the crucial factors for the

management to buy Liebherr wheel loaders.

J Swap Contractors in New Zealand:

Efficiency in heavy operations

What started in 1934 as delivering shoveled riverstone to local customers, ended up becoming a company

supplying over 2.2 million tons of material from ten aggregate quarries per year. Now, 80 years later,

J Swap is one of the top aggregate producers in New Zealand. Among other Liebherr wheel loaders the

largest hydrostatically driven wheel loader in the world, an L 586, is used to cope with the heavy loads

in the 100 % family-owned quarrying business.

Feature: J Swap