For natural gas, For lp gas, 24 installation instructions – Bosch PROTANKLESS GWH 345/450 ESR User Manual

Page 24

6 720 607 909

24

Installation instructions

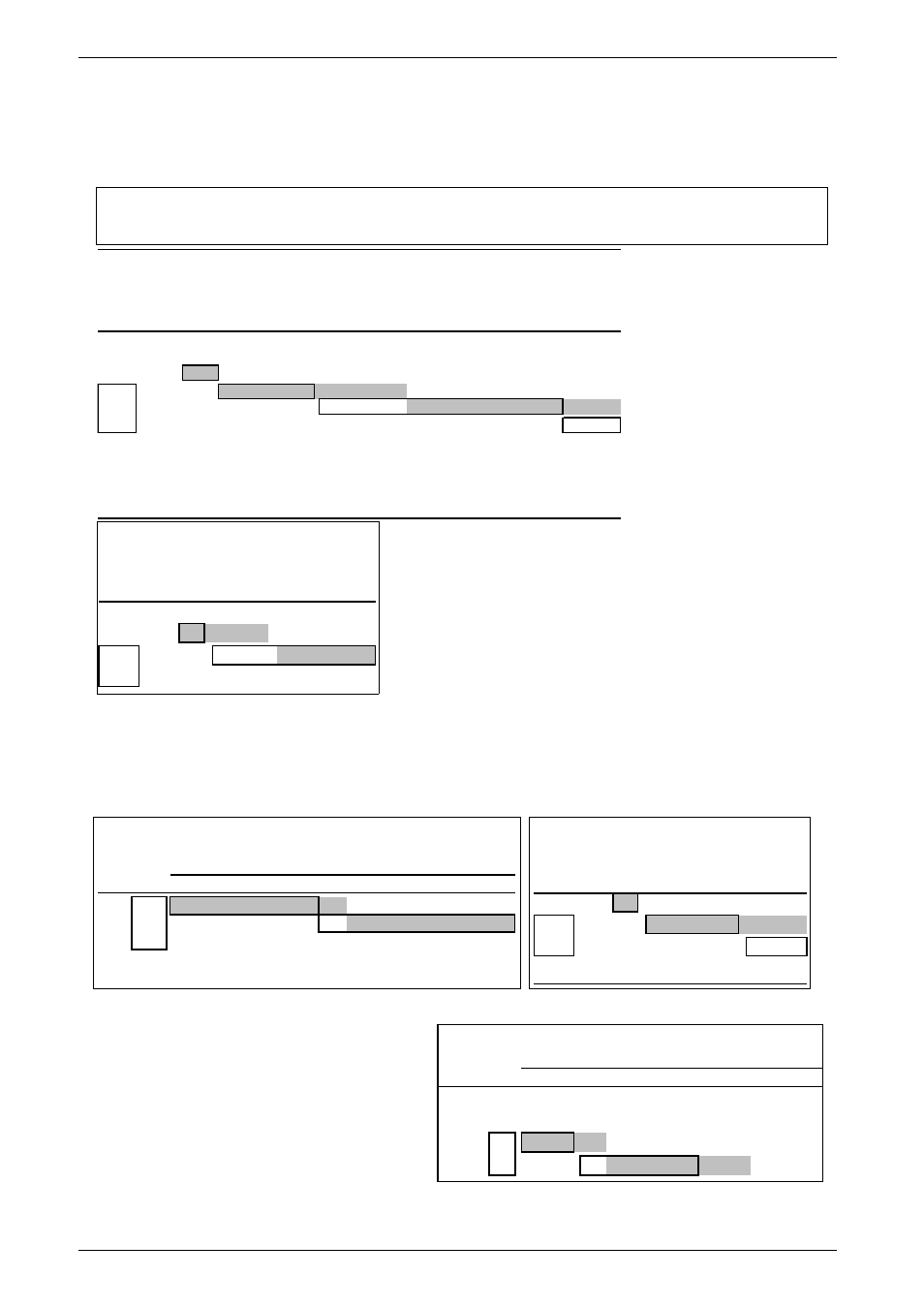

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour for Gas Pressure of 0.5 Psig or less and a Pressure drop

of 0.3 in Water Column (0.75mbar).(Based on a 0.60 Specific Gravity Gas) Btu numbers given in thousands.

Fig. 26

Follow boxed numbers for piping just one GWH-450-ESR (example: ¾” B.I. Natural Gas pipe for 20 ft

(6.1m). will handle 190,000 btu’s (55.7 kWh). For multiple appliances combine the total btu input load and

then refer to applicable chart below. Follow the shaded numbers for just one GWH-345-ESR.

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing

.

Maximum Capacity of Semi-Rigid (flexible, non

corrugated) Tubing in Thousands of BTU per Hour of

Undiluted Liquefied Petroleum Gases (at 11 inches

Water Column Inlet Pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

* Source National Fuel Gas Code NFPA 54, ANSI

Z223.1 - No Additional Allowance is necessary for an

ordinary number of fittings

FOR LP GAS

Maximum Capacity of Pipe in Thousands of BTU per Hour of Undiluted Petroleum Gases (at 11 inches Water Column Inlet

Pressure) (Based on a Pressure Drop of 0.5 Inch Water Column).

* EHD = Equivalent Hydraulic Diameter. The greater the

value of EHD, the greater the gas capacity of the tubing.

Nominal

Iron

Length of Black Iron Pipe, Feet

Pipe

Internal

Size,

Diameter

(inches) (inches)

10

20

30

40

50

60

70

80

90

100

125

150

175

200

1/4

0.364

32

22

18

15

14

12

11

11

10

9

8

8

7

6

3/8

0.493

72

49

40

34

30

27

25

23

22

21

18

17

15

14

1/2

0.622

132

92

73

63

56

50

46

43

40

38

34

31

28

26

3/4

0.824

278

190

152

130

115

105

96

90

84

79

72

64

59

55

1

1.049

520

350

285

245

215

195

180

170

160

150

130

120

110

100

1 1/4

1.380

1050

730

590

500

440

400

370

350

320

305

275

250

225

210

1 1/2

1.610

1600

1100

890

760

670

610

560

530

490

460

410

380

350

320

2

2.067

3050

2100

1650

1450

1270 1150 1050

990

930

870

780

710

650

610

2 1/2

2.469

4800

3300

2700

2300

2000 1850 1700

1600

1500

1400

1250

1130

1050

980

3

3.068

8500

5900

4700

4100

3600 3250 3000

2800

2600

2500

2200

2000

1850 1700

4

4.026

17,500 12,000 9,700 8,300

7,400 6,80 6,200 5,800 5,400 5,100 4,500

4,100 3,800 3500

Tube

size,

inches

EHD*

10

20

30

40

50

60

1/2

18 EHD 82

58

47

41

37

34

3/4

23 EHD 161

116

96

83

75

68

1

30 EHD 330

231

188

162

144

131

1 1/4

37 EHD 639

456

374

325

292

267

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Nominal

iron

Black Iron Pipe

pipe

Length of Pipe, Feet

Inches

10

20

30

40

50

60

80

100

125

150

200

1/2

291

200 160 137 122 110

94

84

74

67

58

3/4

608

418 336 287 255 231 197

175

155

140

120

1

1145 787 632 541 480 434 372

330

292

265

227

Tube

size

inches

EHD*

10

20

30

40

50

60

1/2

18 EHD 129

91

74

64

58

53

3/4

23 EHD 254

183

151

131

118

107

1

30 EHD 521

365

297

256

227

207

1 1/4

37 EHD 971

661

528

449

397

359

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Copper

Outside

Length of Tubing, Feet

diameter

Inch

10

20

30

40

50

60

70

80

90

100

3/8

39

26

21

19

_

_

_

_

_

_

1/2

92

62

50

41

37

35

31

29

27

26

5/8

199 131

107

90

79

72

67

62

59

55

3/4

329 216

181 145

131

121 112 104

95

90