Warning, Notice – Burnham PVG User Manual

Page 11

11

a. Minimum twelve (12) inches above grade plus

normally expected snow accumulation level, or

seven (7) feet above grade if located adjacent

to public walkway. Do not install over public

walkway where local experience indicates

appliance flue gas vapor or condensate creates a

nuisance or hazard.

b. Minimum three (3) feet above any forced air

inlet located within ten (10) feet.

c. Minimum four (4) feet below, four (4) feet

horizontally from, or four (4) feet above any

door, window, or gravity air inlet.

d. Minimum four (4) feet horizontally from electric

meters, gas meters, regulators, and relief valves.

This distance may be reduced if equipment is

protected from damage due to condensation or

vapor by enclosure, overhangs, etc.

e. Minimum twelve (12) inches from overhang or

corner of building.

9. Enclose vent passing through occupied or

unoccupied spaces above the boiler with material

having a fire resistance rating of at least equal to the

rating of the adjoining floor or ceiling. Maintain

minimum clearances to combustible materials. See

Figure 1.

Note: For one or two family dwellings, fire

resistance rating requirement may not need to be

met, but is recommended.

10. Plan venting system to avoid possible contact with

plumbing or electrical wires. Start at vent connector

on top of boiler and work towards vent terminal.

11. Once a vent pipe manufacturer and system is chosen

never mix and match vent systems.

12. If a non-standard length pipe is required:

Gasketed Vent System: The use of the adjustable

length pipe (P/N 8116319U) is recommended to

complete a non-standard pipe length. This pipe

requires a minimum installed length of 12¾ inch

and can adjust across a 7 inch gap up to a maximum

of 19¾ inch long. (Note for the adjustable pipe

the installed length should be measured from the

centerline of the bead on the male end of the first

pipe to the end of the female pipe excluding the

locking band of the second pipe with a single

gasket.) Only in the event the adjustable length pipe

is not sufficient a standard length pipe may be cut

using the procedure outlined below for the Gasket-

Less Vent System.

WARNING

Never exceed maximum installed length of 19¾

inches for adjustable length pipe.

Risk of flue gas leakage is possible.

NOTICE

Cut must be square with pipe and filed or

sanded smooth before joining. Carefully ensure

roundness of cut pipe by hand with gloves before

installing. Seal joint with RTV specified in this

manual.

C.

Install Vent Pipe, Burnham Gasketed Vent System.

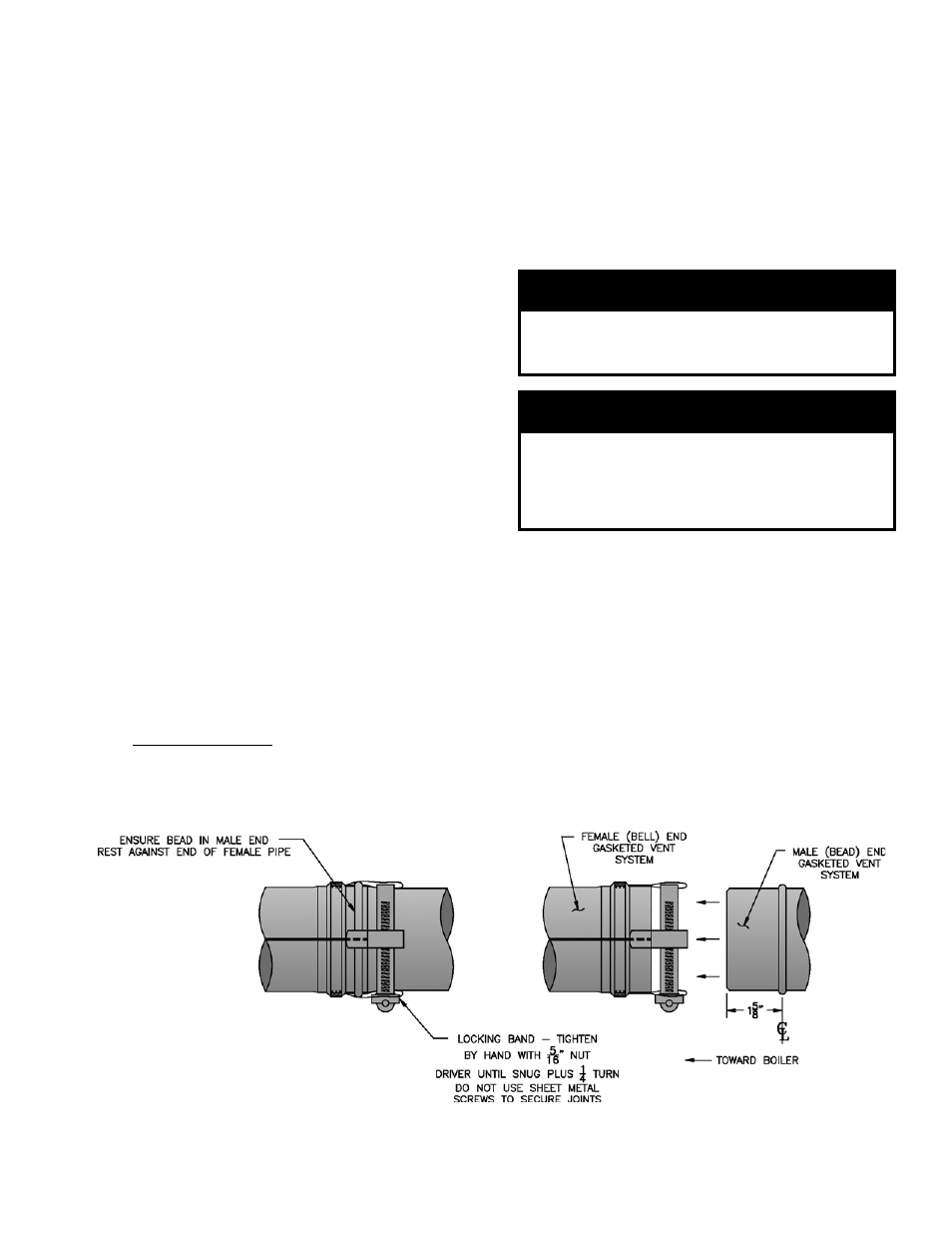

1. Procedure for Joining Burnham Gasketed Vent Pipe

and Fittings. See Figure 3.

a. Wipe the male end of each joint using an alcohol

pad to remove any dirt and grease.

b. Align weld seams in pipes and use a slight

twisting motion to FULLY insert male end into

female end of joint. Ensure bead in male end

of pipe is below locking band and rest against

the end of the female pipe. Verify the factory-

installed gasket is not dislodged or cut.

Figure : Burnham Gasketed Vent Joint Detail