Adjusting downward travel of saw blade, Adjusting 90 ° and 45 ° bevel stops, Adjusting blade parallel to table slot – Black & Decker BT2000L User Manual

Page 53

53

DISCONNECT MACHINE FROM POWER SOURCE.

1. Loosen the bevel lock handle and move the cutting arm all the way to the right. Tighten the bevel lock handle.

2. Place one end of a square (A) Fig. 22 on the table and the other end against the blade. Check to see if the blade

is 90° to the table (Fig. 22).

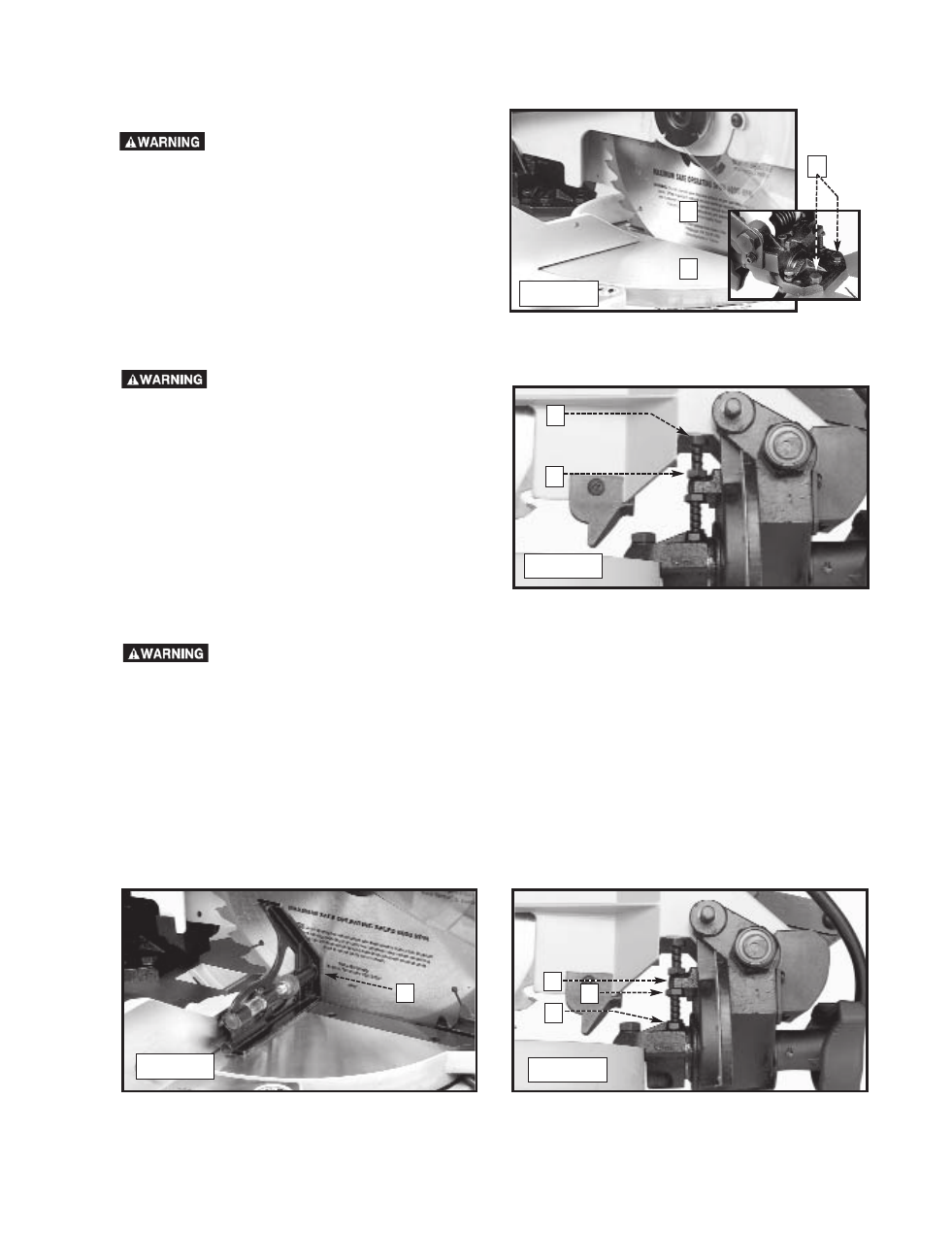

3. If an adjustment is necessary, loosen the locknut (A) Fig. 23. Turn the screw (B) until the head of the screw

contacts the casting (C) when the blade is 90° to the table. Tighten the locknut (B).

4. Loosen the bevel lock handle and move the cutting arm all the way to the left bevel position. Tighten the bevel

lock handle.

5. Use a combination square (A) Fig. 24 to see if the blade is at 45° to the table.

6. If an adjustment is necessary, loosen the locknut (A) Fig. 25. Turn the screw (B) until the screw (B) contacts the

casting (C) when the blade is 45 degrees to the table. Tighten the locknut.

7. Check to see that the bevel pointer (A) Fig. 26 is pointing to the 45° mark on the bevel scale. To adjust the bevel

pointer (A), loosen the screw (B) and adjust the pointer (A). Tighten the screw (B) securely.

DISCONNECT MACHINE FROM POWER

SOURCE.

1. The downward travel of the saw blade should be

limited to prevent the saw blade from contacting

any metal surfaces of the machine. This adjustment

is made by loosening the locknut (A) Fig. 21, and

turning the adjusting screw (B) in or out.

2. Lower the blade as far as possible. Rotate the

blade by hand to ensure that the teeth do not

contact any metal surfaces. Adjust if necessary.

3. After the downward travel of the saw blade has

been adjusted, tighten the locknut (A).

ADJUSTING DOWNWARD TRAVEL OF SAW BLADE

Fig. 21

A

B

ADJUSTING 90° AND 45° BEVEL STOPS

A

Fig. 22

Fig. 23

C

B

A

DISCONNECT MACHINE FROM POWER

SOURCE.

1. Lower the cutting arm. The saw blade (A) Fig. 20

should be parallel to the left edge (B) of the table

opening.

2. If an adjustment is necessary, loosen two screws

(C) Inset, and move the cutting arm until the blade

is parallel with the left edge (B) of the table

opening and centered in the slot. Then tighten the

two screws (C).

A

B

C

Fig. 20

ADJUSTING BLADE PARALLEL TO TABLE SLOT