Vollrath U421 Water Cooled User Manual

Page 33

25

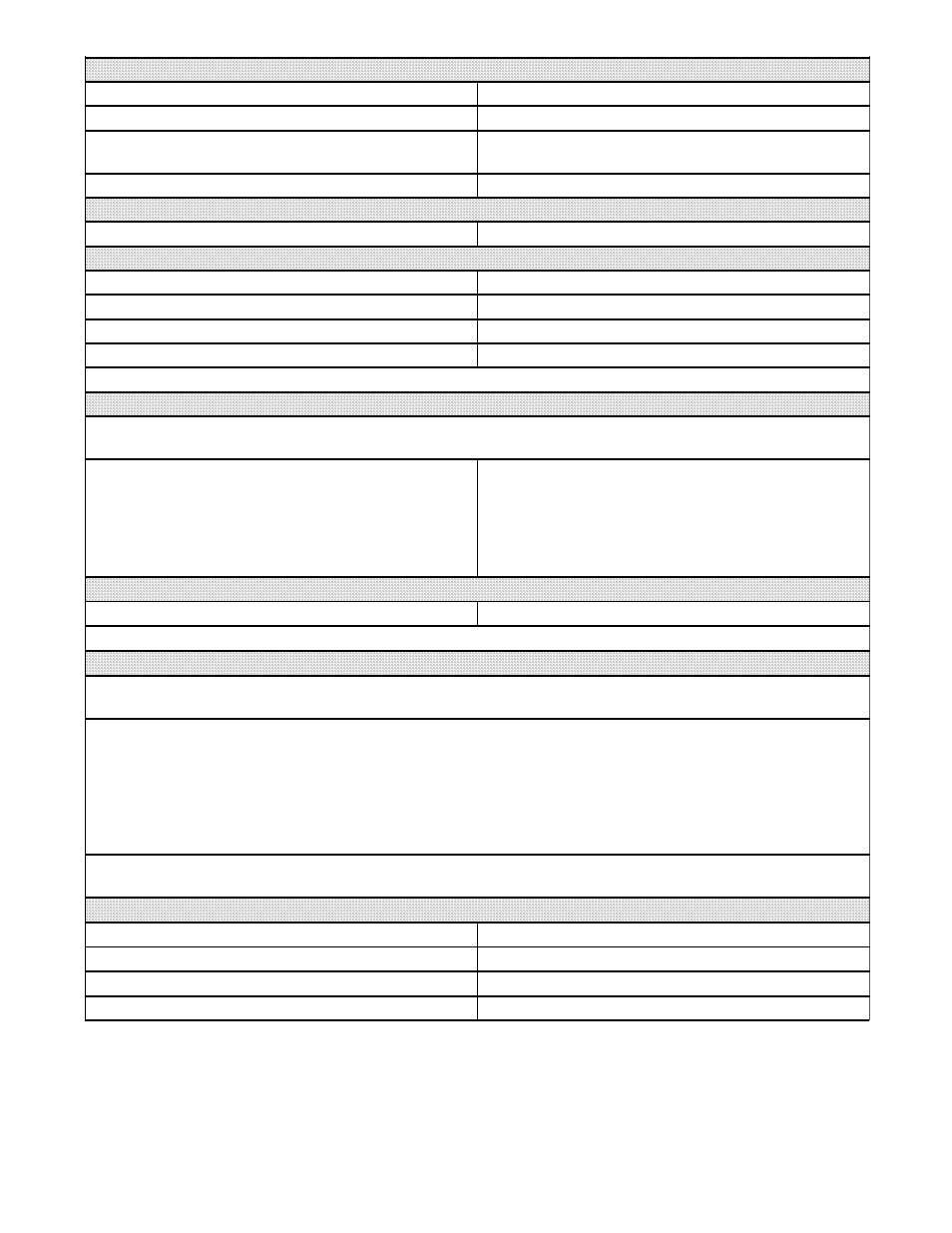

5. REPLACEMENT MIX PUMP HOSE WON'T FEED THROUGH PUMP

Feeding hose into discharge hole of mix pump cover.

Feed hose into pick-up side of cover.

Hose ends not cut squarely.

Carefully cut hose end off squarely (no tails).

Force feeding too quickly.

Gently and slowly assist feeding of hose up into pick-up

hose side of cover.

Pump motor not running.

Turn on motor switch. Also see Item 1 above.

6. AIR EXITING MIX PICK-UP HOSE

Pickup tube check valve missing.

Contact local Stoelting Distributor.

7. DISPENSED PRODUCT AIR "POPS"

Overrun setting too high.

Reposition/replace mix pump hose.

Mix pump hose service life is exceeded.

Reposition/replace mix pump hose.

Overdrawing the freezer's capacity.

Reduce dispense rate.

Recent "mix-out" condition.

Open spigot fully and allow excess air to "belch" out.

NOTE: ALSO SEE 2 & 4 ABOVE.

8. MIX LEAKAGE FROM PUMP

CAUTION: To prevent mix pump damage from dried mix deposits, immediately disassemble and clean

pump.

Mix pump hose service life is exceeded.

Remove mix pump hose. Disconnect pump from power

source. Remove mix pump cover/clamp. THOROUGHLY

rinse three squeeze rollers using a spray bottle filled with

hot water. Thoroughly clean all mix from pump. See Sec.

4.2 for hose replacement. Lubricate squeeze roller

bearings, see Item #10 below.

9. PUMP HAS POOR CAPACITY

Lift and run limits are exceeded.

Pump is limited to 10' lift, 20' run.

NOTE: Also see 2, 4, 6 & 7.

10. PUMP IS NOISY/SQUEAKING

NOTE: THE ACTION OF THE AIR COMPRESSOR ROCKING ARM CREATES A REPETITIVE CLICKING SOUND DURING

OPERATION. THIS IS NORMAL.

NOTE: THE PERISTALTIC MIX PUMP HAS THREE SQUEEZE ROLLERS WHICH USE SELF LUBRICATING BEARINGS. IF

SQUEAKING EXISTS WITH THE MIX PUMP HOSE IN PLACE, AND STOPS WITH THE HOSE REMOVED, THE SQUEEZE

ROLLER BEARINGS CAN BE LUBRICATED USING A SILICONE BASED SPRAY. REMOVE THE MIX PUMP HOSE.

DISCONNECT PUMP FROM ELECTRICAL POWER. REMOVE FOUR COVER/CLAMP THUMBSCREWS. REMOVE ENTIRE

COVER/CLAMP AS ONE UNIT. SPRAY SILICONE BASED LUBRICANT ON EACH END OF EACH SQUEEZE ROLLER.

SPIN ROLLERS TO WORK LUBRICANT INTO BEARINGS. REPEAT AS NEEDED.

CAUTION: DO NOT USE CLEANING/DISSOLVING TYPE LUBRICANTS LIKE WD-40. THESE LUBRICANTS

ARE NOT BEARING FRIENDLY AND WILL ACCELERATE BEARING WEAR.

11. MIX IN AIR HOSES

Air/mix tee above black cover/clamp.

Air/mix tee must be below black cover/clamp.

Air leak.

Tighten all hose clamps.

Mix hose on wrong air/mix tee fitting.

Refer to diagram for correct hose connections.

Pressure control manifold o-ring leak.

Check o-ring and manifold; replace as required.