Vollrath U421 Water Cooled User Manual

Page 25

17

D.

Clean the rear seal surface from inside of the freezer

barrel.

E.

Remove the rear drip tray by pulling from side panel.

Clean and replace drip tray.

F.

Assemble freezer parts. (Refer to section 3.13 for

assembly of freezer parts).

NOTE

Any cleaning procedure must always be followed

by sanitizing before filling freezer with mix. (Refer to

section 3.3)

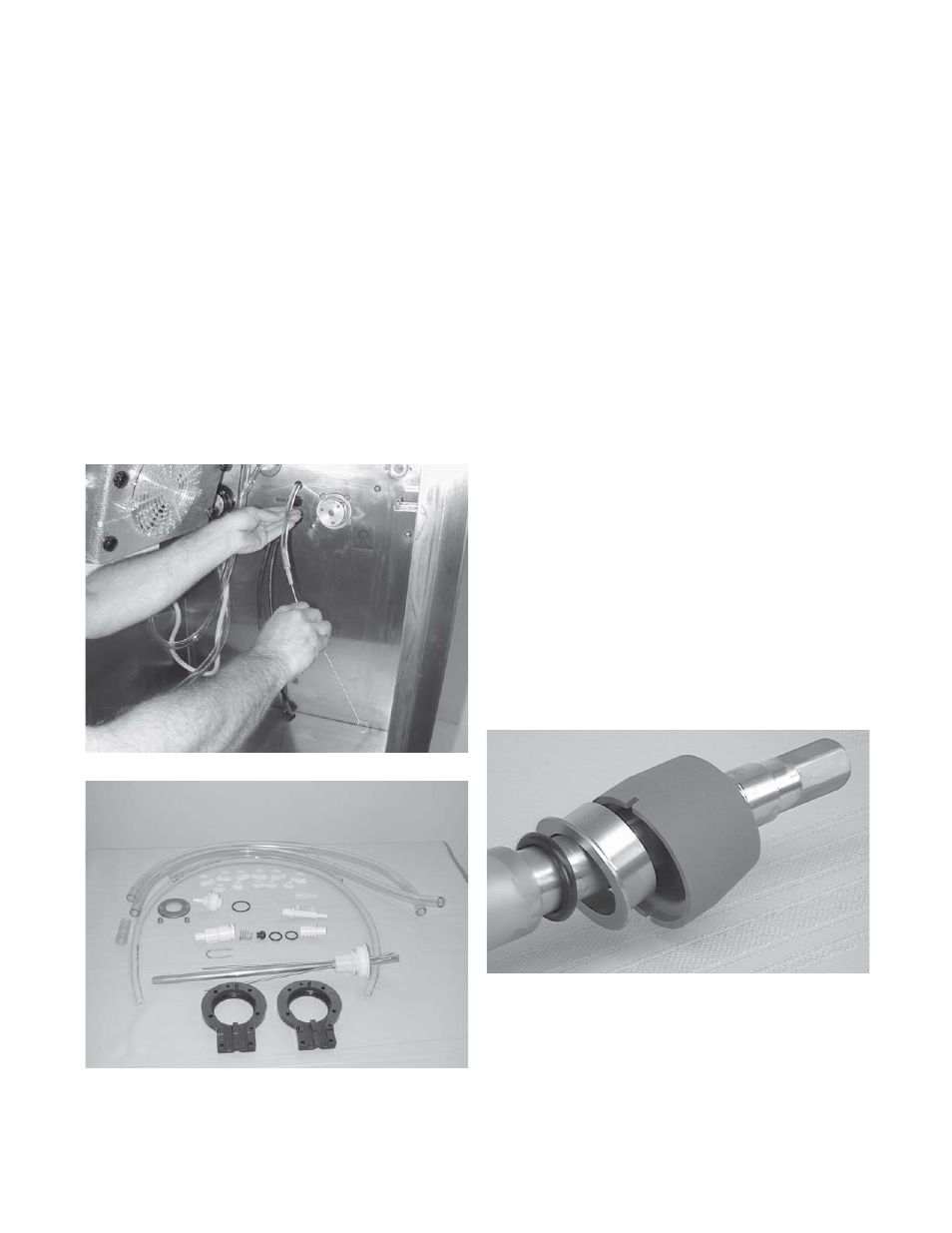

3.11 MIX PUMP CLEANING

The mix pump is approved for CIP (clean in place) and is

thoroughly cleaned as cleaning solutions are pumped thru

the freezer. We recommend completely disassembling

the pump and connecting tubing every 14 days for inspection

of parts to confirm the CIP has been properly performed. If

any residue is detected clean or replace those parts. Clean

parts in warm soapy water using brushes provided. See

Figures 21 and 22.

Figure 21. Cleaning Air Tube

Figure 22. Removable Parts

3.12 SANITIZE FREEZER PARTS

A.

Use a sanitizer mixed according to manufacturer's

instructions to provide a 100 parts per million strength

solution. Mix sanitizer in quantities of no less than 2

gallons (7.5 liters) of 120°F (49°C) water. Allow the

sanitizer to contact the surfaces to be sanitized for 5

minutes. Any sanitizer must be used only in accor-

dance with the manufacturer's instructions.

B.

Place all parts in the sanitizing solution, then remove

and let air dry.

C.

Using this sanitizing solution and the large barrel

brush provided, sanitize the barrel by dipping the

brush in the sanitizing solution and brushing the

inside of the barrel.

3.13 ASSEMBLY OF FREEZER

To assembly the freezer parts, refer to the following steps:

NOTE

Petro-Gel sanitary lubricant or equivalent must be

used when lubrication of freezer parts is specified.

NOTE

The United States Department of Agriculture and

the Food and Drug Administration require that lubri-

cants used on food processing equipment be certi-

fied for this use. Use Lubricants only in accordance

with the manufacturer's instructions.

A.

Assemble all "O" rings onto parts dry, without lubri-

cation. Then apply a thin film of sanitary lubrication

to exposed surfaces of the "O" rings.

B.

Lubricate rear seal area on auger with a thin layer of

sanitary lubricant. Install the rear seal (Figure 23)

"O" ring. Lubricate and install rear seal.

Figure 23. Rear Seal Lubrciation

C.

Lubricate the hex drive end of auger with a small

amount of white socket lubricant. A small container

of socket lubricant is shipped with the freezer.

D.

Screw the springs onto the studs in plastic flights.

Spring must be screwed into the flights com-

pletely to provide proper tension. Figure 24.

З

З

З

З

З

Й

Й

Й

Й

Й

Й

Й

Й

Й

Й

Lubricate with Petrogel

Lubricate with

Socket

Lubricant

К

К

К

К

К