Duff-Norton Machine Screw Rotating 500lb - 1 Ton User Manual

Page 8

8

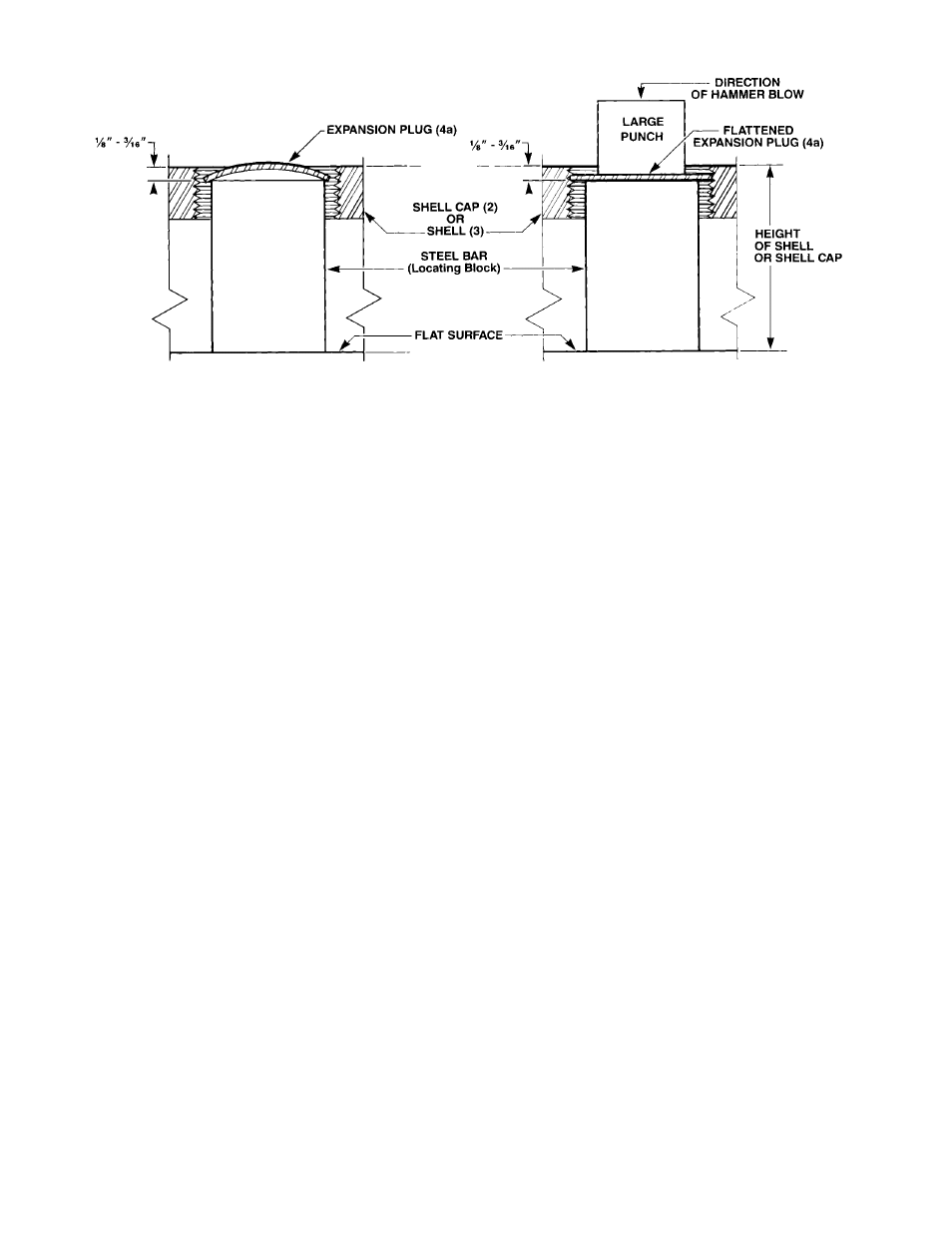

Figure 2-1. Expansion Plug Replacement

other worm bearing on end of worm shaft, insert

other worm shaft end through worm housing, tap

lightly to position worm and both bearings and snap

in second retainer ring.

9. Install screw (5) and gear (6) assembly into shell (3).

10. For 1-ton models-install bearing (7) cup into shell

cap (2). For 1/4-ton and 1/2-ton models - place top

load bearing (7) on hub of gear (6).

11. Fill housing (3) with grease.

12. Install shell cap (2) and screw down until tight.

Note

Shell cap flange does not necessarily have to bear

against top of shell. There will usually be a gap. This

will put a slight drag on the worm. If worm is hard to

turn, back off slightly on shell cap.

13. Install set screws (1) in shell cap(2). Tap shell cap

sharply with hammer and re-tighten set screws

Note

If new parts have been installed it may be necessary

to spot holes for set screws.

14. Brush screw (5) with light film of grease and thread

lifting nut (23) on screw (5). The face of lifting nut

flange should be toward shell (3).

15. Operate unit to insure proper functioning of all compo-

nents prior to installation and use.

Assembly is now complete.