General information – Duff-Norton Machine Screw Rotating 500lb - 1 Ton User Manual

Page 3

3

General Information

1-1.

General

This manual contains maintenance instructions for Duff

Norton

1/4 through 1- ton rotating machine screw actua-

tors. It describes and details procedures for installation,

disassembly, cleaning, inspection, and assembly of these

actuators.

1-2.

Applications

The actuators described and illustrated in this manual are

intended for industrial use only and should not be used to

lift, support or otherwise transport people unless you

have a written statement from Duff-Norton which autho-

rizes the specific actuator unit, as used in your applica-

tion, as suitable for moving people.

Section I

1.3. Specifications

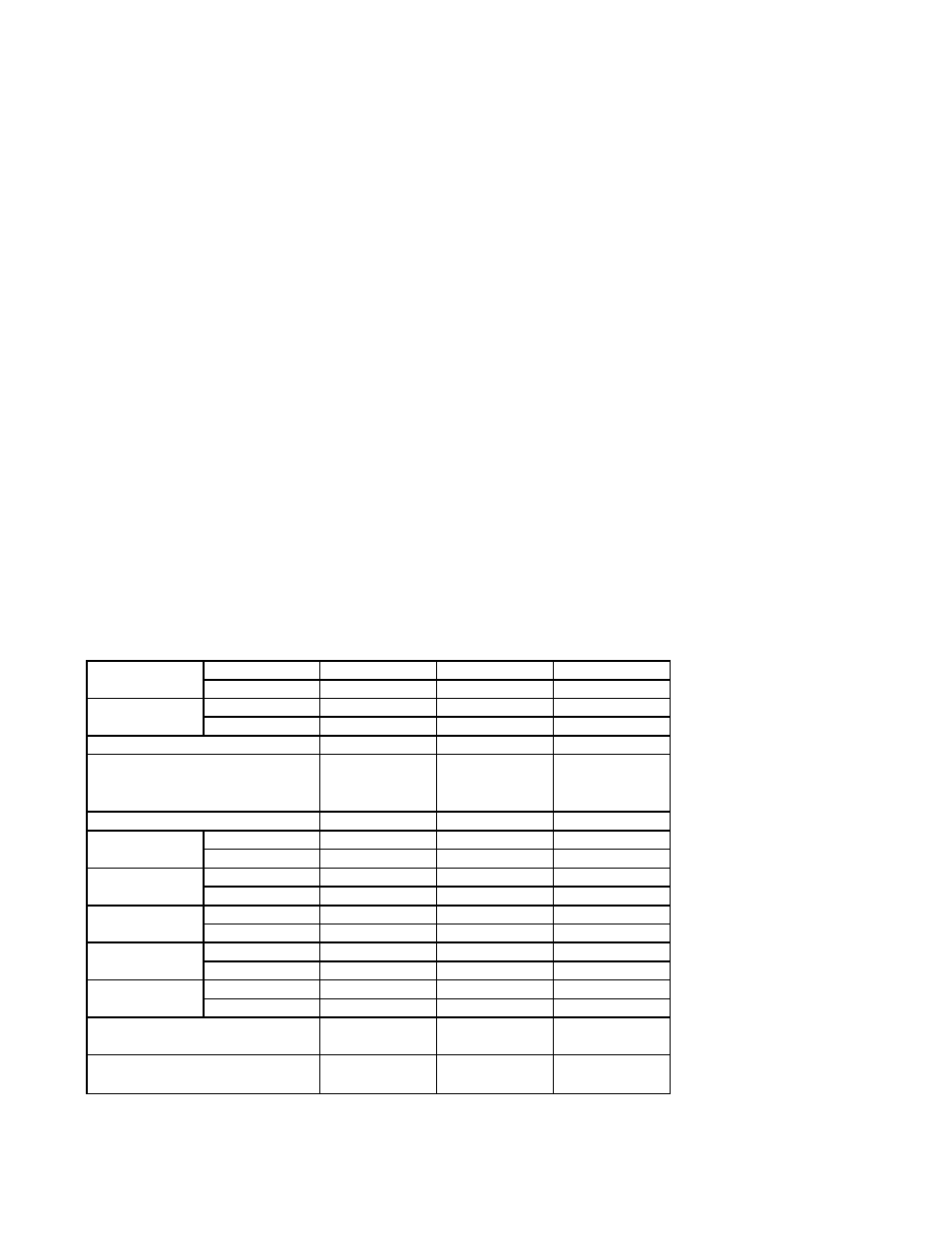

Table 1. 1/4-ton through 1-ton Series Rotating Machine Screw Actuators

*

For loads from 25% to 100 % of Actuator load rating. Torque requirements are approximately proportional to the load.

Actuator No. Upright

UM2556

UM2626

UM2502

Standard

Inverted

DM2556

DM2626

DM2502

Actuator No. Upright

UM3056

UM3626

UM3502

Special

Inverted

DM3056

DM3626

DM3502

Rated Load (lb)

500

1000

2000

Diameter of

1/2

5/8

3 / 4

Lifting Screw

.250 Pitch

.125 Pitch

.200 Pitch

(inches)

ACME

ACME

ACME

Base Size (in.)

2 1/4 x 4

2 1/4 x 4

2 3/4 x 5

Worm Gear

Std. Ratio

5:1

5:1

5:1

Ratios

Optional

-

-

20:1

Turns of Worm

Std. Ratio

20

40

25

for 1" Raise

Optional

-

-

100

Maximum H.P.

Std. Ratio

1/3

1/3

1/2

Per Actuator

Optional

-

-

1/4

Torque at Full

Std. Ratio

13

21

55

Load* (in-lbs)

Optional

-

-

25

Jack Efficiency

Std. Ratio

33.0

20.0

24.5

Rating (%)

Optional

-

-

14.0

Weight with Base

Raise of 6" (lb)

2.3

2.3

5.0

Weight for Each

Additional 1" Raise (lb)

0.1

0.1

0.3