Instruction manual ni-492e – WIKA TXA User Manual

Page 5

INSTRUCTION MANUAL

NI-492E

Rev. 0 01/05

9 - PUTTING INTO OPERATION

As the signal transmitted by the instrument is used in a complex

system, it is necessary that the means of putting it into operation

are established by those in charge of the plant.

The instrument starts operating as soon as it is powered.

In case of explosionproof instruments (Series TXA and TXN),

initial inspections are to be carried out according to customer

procedures and at least in accordance with Standards EN-60079-

17 and EN-50281-1-2.

10 - FUNCTIONAL VERIFICATION

It will be carried out according to customer control procedures.

Explosionproof instruments (Series TXA, TXN) installed in

hazardous areas due to the presence of inflammable dusts

should be periodically cleaned externally to avoid dust

accumulation.

Instruments Series TXS may be checked on site if installation has

been made according to Fig. 9 to 12.

Instruments Series TXA, TXN may be checked on site but if

testing equipments are suitable for the environment and electric

supply is off.

Otherwise it is necessary to stop them working, remove them and

carry out checks in a test room.

The verification consists in checking the calibration value and

adjusting it if required (see §5).

In case of explosionproof instruments (Series TXA and TXN)

inspections of the electrical installation are to be carried out also

according to customer procedures and at least in accordance

with Standards EN-60079-17, EN-50281-1-1.

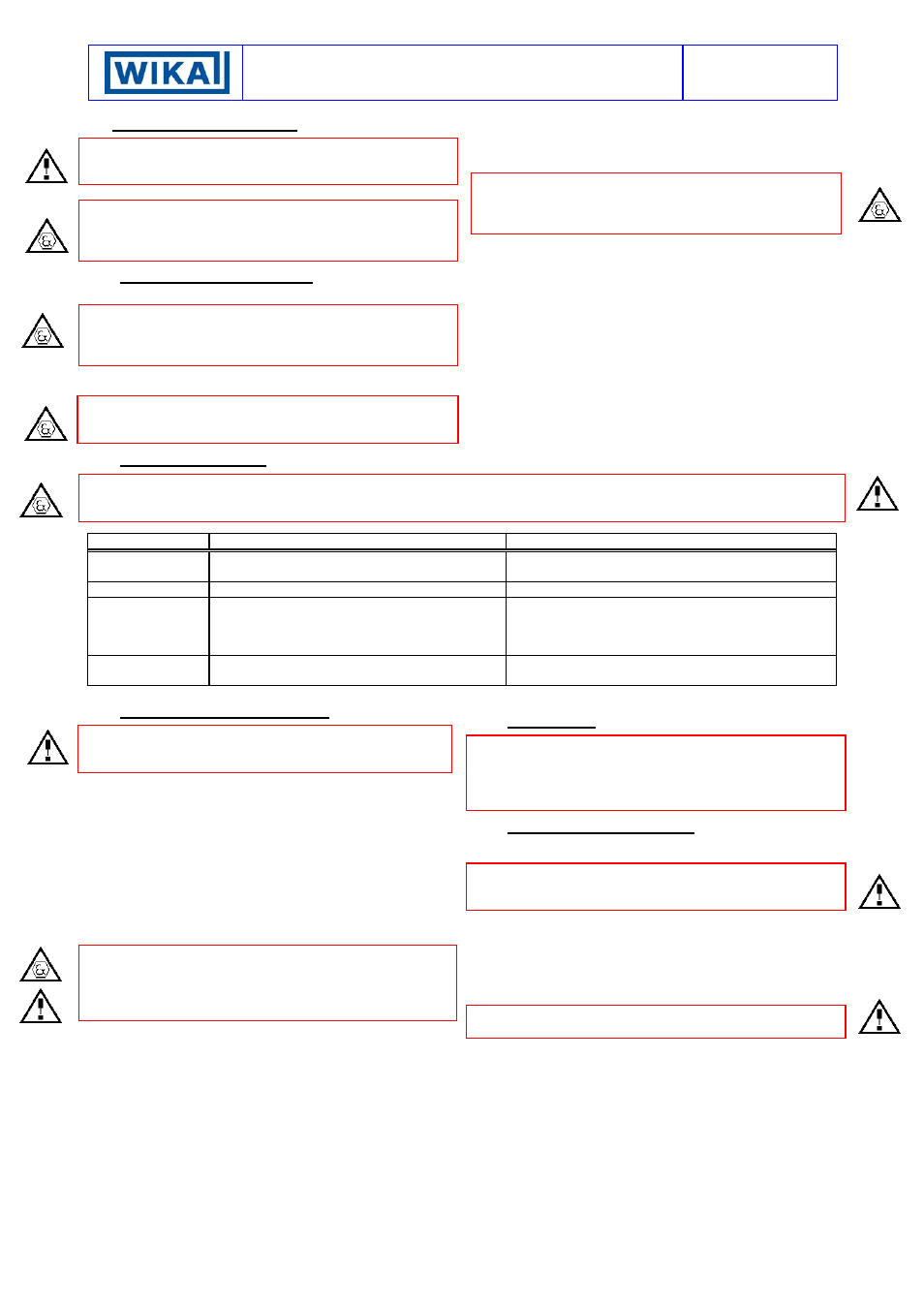

11 - TROUBLE SHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our workshop, especially

for instruments with explosionproof certificate; this is to guarantee the user the total and correct restoration of the product

original characteristics.

MALFUNCTION PROBABLE

CAUSE

REMEDY

Set point shift

Deposits on thermowell or bulb

Filling fluid leakage

Check and clean surfaces

Replace the instrument

Slow response

Deposits on thermowell or bulb

Check and clean surfaces

No actuation

Loosened electrical joints

Interrupted or short-circuited electrical line

Microswitch contacts damaged

Filling fluid leakage

Check all electrical joints

Check the conditions of the electrical line

Replace the instrument

Replace the instrument

Undue actuation

Accidental shocks

Interrupted or short-circuited electrical line

Modify the mounting

Check the conditions of the electrical line

12 - STOPPING AND DISMOUNTING

Before starting the following operations, ensure that plant and

equipments have been put in conditions allowing to carry out

them safely.

Remove the power supply (signal) from the electric line.

With reference to Fig. 5.

Loosen stuffing gland (2) taking care not to twist capillary and its

armor.

Loosen and slide out union (3), then exctract bulb from

thermowell holding the capillary, without twisting it.

With reference to Fig. 9.

Unscrew the electrical three-piece joint. Remove junction box

cover and disconnect electric wires from terminals and ground

screws.

Unscrew fixing screws of junction box and remove instrument

sliding out the electric wires.

Replace the junction box cover, insulate and protect loose

leadwires. Temporarily plug the thermowell. In case of

explosionproof instruments (Series TXA, TXN) it is recommended

to follow - at least – the Standards EN-60079-17 and EN-50281-

1-2 for the withdrawal from service of electrical apparatus.

13 - DEMOLITION

The instruments are mainly made of stainless steel and

aluminium; therefore, once the electrical parts have been

dismounted and the parts coming into contact with fluids which

could be harmful to people or to environment have been properly

dealt with, they can be scrapped.

14 - NOTES FOR INSTALLATION

14.1

TEMPERATURE SWITCHES CLASS SAMA II A

A difference in height between bulb and case exceeding two

meters causes a systematic error in the set point calibrated value

(“bulb elevation error”).

This error can be corrected during calibration by either increasing

or decreasing the set point value by a constant depending on the

difference in height foreseen for the installation. The “bulb

elevation error” can be corrected using the table attached to our

technical instruction IS-TC.401E, available on request.

14.2

TEMPERATURE SWITCHES CLASS SAMA II C

The temperature switch must be installed with a difference in

height between bulb and case not exceeding two meters.

With a difference of approximately two meters the set point value

fixed during calibration may be affected by an error depending on

the normal reference temperature, the working temperature and

the set point temperature. In the worst operating conditions the

set point temperature value fixed during calibration may be

affected by a maximum error of 1,5°C. For further clarification

request IS-TC.401E.