Instruction manual ni-492e, Do not turn – WIKA TXA User Manual

Page 4

INSTRUCTION MANUAL

NI-492E

Rev. 0 01/05

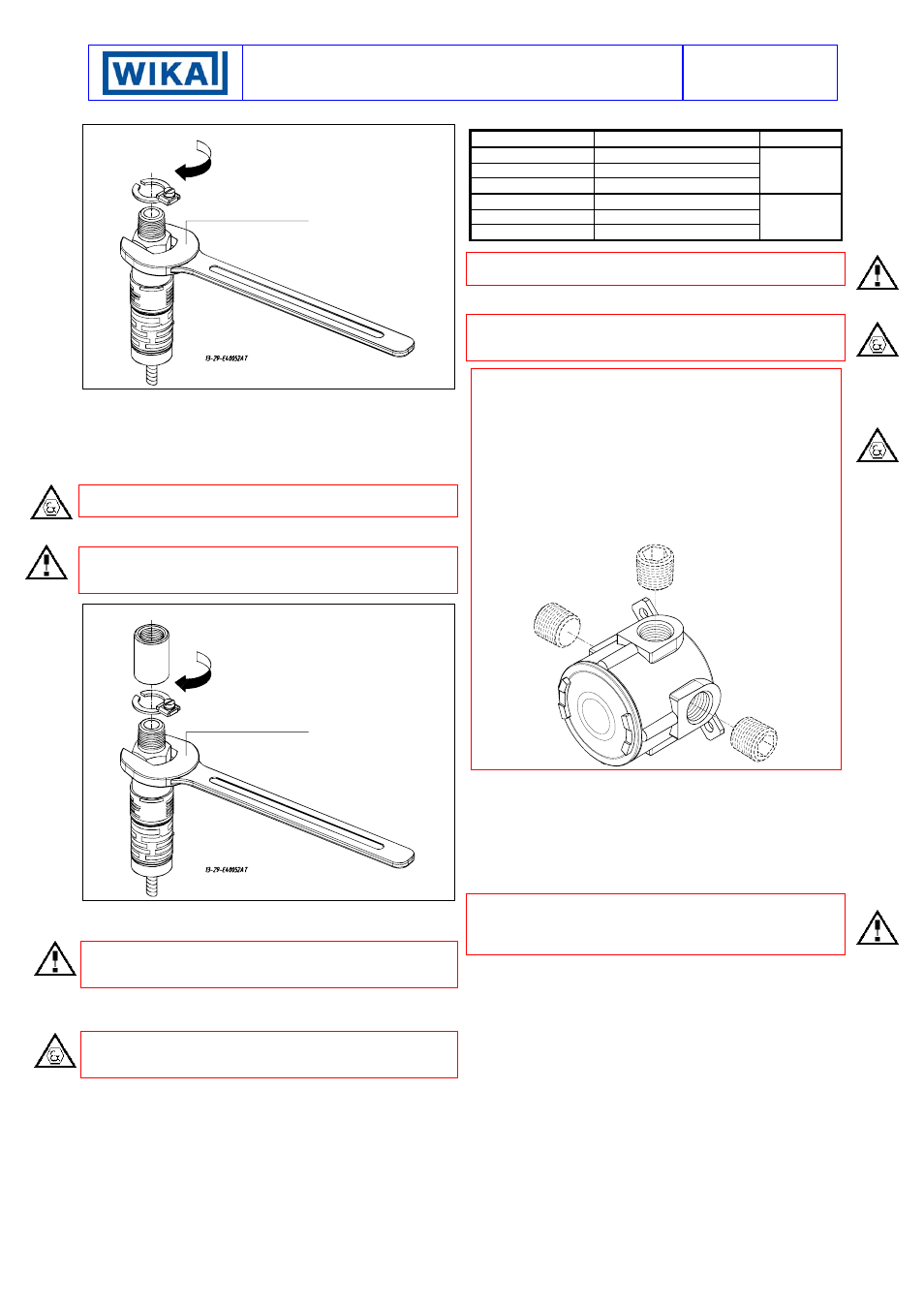

Fig. 6 -

Mounting of ground device

DO NOT TURN

8.3.2 MOUNTING WITH CABLE PROTECTED BY FLEXIBLE

TUBING

Mount, if provided, the external ground device on the electrical

connection of the instrument. This device is to be threaded on,

while holding the electrical connection steady with a 27 mm

wrench on hex, until it reaches the bottom of the thread (Fig. 6).

The external ground screw is obligatory for explosionproof

constructions.

If the flexible tubing is fitted with a male thread, apply a sleeve to

the electrical connection.

CAUTION: the sleeve is to be threaded on while holding the

electrical connection steady with a 27 mm wrench on hex

(Fig.7)

.

Fig. 7 -

Mounting of adaptors

DO NOT TURN

8.3.3

MOUNTING WITH CABLE PROTECTED BY METAL

TUBING

CAUTION: mounting with cable protected by metal tubing is to be

carried out avoiding any torque on the electrical connection while

assembling the various fittings (Fig. 7).

In order to make the instrument removal easier for check and

calibration it is advisable to apply the instrument a junction box

provided with terminals.

CAUTION: accessories used for installation have to be certified

according to standards EN 50014, 50018, EN 50281-1-1 and

guarantee the degree of protection of the instrument (IP65).

8.3.4

MOUNTING WITH INSTRUMENT FITTED WITH

JUNCTION BOX

Models fitted with junction box feature three cable entries, three-

or six-terminals block with terminals identification plate, internal

and external grounding connections.

Terminals are identified as follows:

Identification No.

Function

Micro No.

1 Common

2 Normally

Open

3 Normally

Closed

1

4 Common

5 Normally

Open

6 Normally

Closed

2

Mounting with cable protected is to be carried out so as to

prevent possibile condensate from entering the junction box

The junction box is to be surface mounted using the bracket

suppiled with it.

CAUTION: accessories used for installation have to be certified

according to standards EN 50014, 50018, EN 50281-1-1 and

guarantee the degree of protection of the instrument (IP65).

CAUTION: cable entries not used must be plugged and sealed

with the plugs provided so as to prevent raining water or other

from entering the junction box. In case of explosionproof

instruments these plugs, if not correctly mounted and

blocked to prevent their removal, do NOT guarantee the

mode of protection EEx-d. Furthermore, in order to guarantee

the degree of protection IP65 and the non-loosening of blocking

joint or packing gland, it is prescribed to seal the threads of

connection with the same anaerobic sealant used for the plugs.

For instance, a sealant like Loctite ® 648 can be applied on the

thread of plugs, blocking joint or packing gland before screwing

them on the box.

8.4

WIRING

The cable used for electric wirIng has a 7 mm OD silicone sheat

for one contact models, 8 mm OD for two contact models. Each

wire has a section of 0,5 mm

2

(20 AWG) and is silicone insulated.

Wires ends are factory tinned. The colour of insulator defines the

contact function (see Fig. 3 and stampings on slot cover).

Before starting wiring, check that electric lines are not

powered.

The instrument is to be grounded according to applicable

electrical codes. Make use of the internal yellow-green wire and,

if the cable is not protected by metal tubing, connect the external

screw of the groundig device supplied with the instrument.

Should the instrument be fitted with junction box, make sure that

no deposits or wire ends remain inside the box. The wiring

completed, put the cover on and tighten it.

8.5

SPECIAL NOTE FOR THE INSTALLATION OF

TEMPERATURE SWITCHES CATEGORY 3GD, MODE OF

PROTECTION EEx - nC

Explosionproof instruments Series TXN are to be installed using

electric accessories prescribed for this execution. For instance,

junction boxes are to be suitable for mode of protection n. Apply

to standards EN-50021 for any construction detail and to EN-

60079-14, EN-50281-1-2 for installation.