Instruction manual ni-492e – WIKA TXA User Manual

Page 3

INSTRUCTION MANUAL

NI-492E

Rev. 0 01/05

6.1

PRELIMINARY OPERATIONS

Slide up the adjustment cover (Fig. 2, 1).

6.2

CALIBRATION CIRCUIT AND OPERATIONS

Prepare the control circuit as indicated in Fig.4.

The warning lamps should be connected to the terminals NA or

NC according to the required contact action.

Circuit C/NA

• This circuit closes with temperature on rise and opens with

temperature on fall when temperature reaches the set point.

Circuit C/NC

• This circuit opens with temperature on rise and closes with

temperature on fall when temperature reaches the set point.

The test instrument should have a measurement range

approximately equal to or slightly wider than the temperature

switch range and should have an accuracy consistent with the

precision required to calibrate the set point.

The temperature switch must be mounted in its normal

installation position, i.e. with the stem or capillary downwards.

Adjustments

Modify the temperature in the circuit up to the desired

microswitch set point value.

Turn the adjusting bush using the adjustment rod until the relative

lamp turns on (or turns off); then turn it in the opposite direction

until the lamp turns off (or on). Slowly turn the bush again until

the lamp turns on (or off).

If the instrument is equipped with two contacts, remember that

they are released simultaneously but within the specification

tolerance.

Fig. 4 -

Calibration circuit

TS - Temperature switch

TC - Test thermometer

VT - Thermostatic bath

6.3

FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.

Close the adjustment slot by sliding down the slot cover (Fig. 2,

1), then seal with lead the instrument.

7 - INSTRUMENT PLUMBING

The plumbing (see Fig. 2), aimed as a guarantee against possible

tampering of the calibration, can be carried out using a flexible

steel wire (2), 1 mm

2

in section, wound up around the case in the

groove purposely provided.

8 - MOUNTING AND CONNECTIONS

8.1

NOUNTING

Mount instruments with capillary either on pipe or surface by

means of the proper bracket (see Fig. 8 and 9).

Select a location where possible shocks and temperature

variations remain within tolerable limits.

CAUTION: for instruments with capillary, the difference in height

between bulb and case is not to exceed two meters. If it does,

adjust set point temperature value according to the table given in

instruction IS-TC.401E.

For bracket mounting, see NI-292E.

8.2

BULB AND CAPILLARY

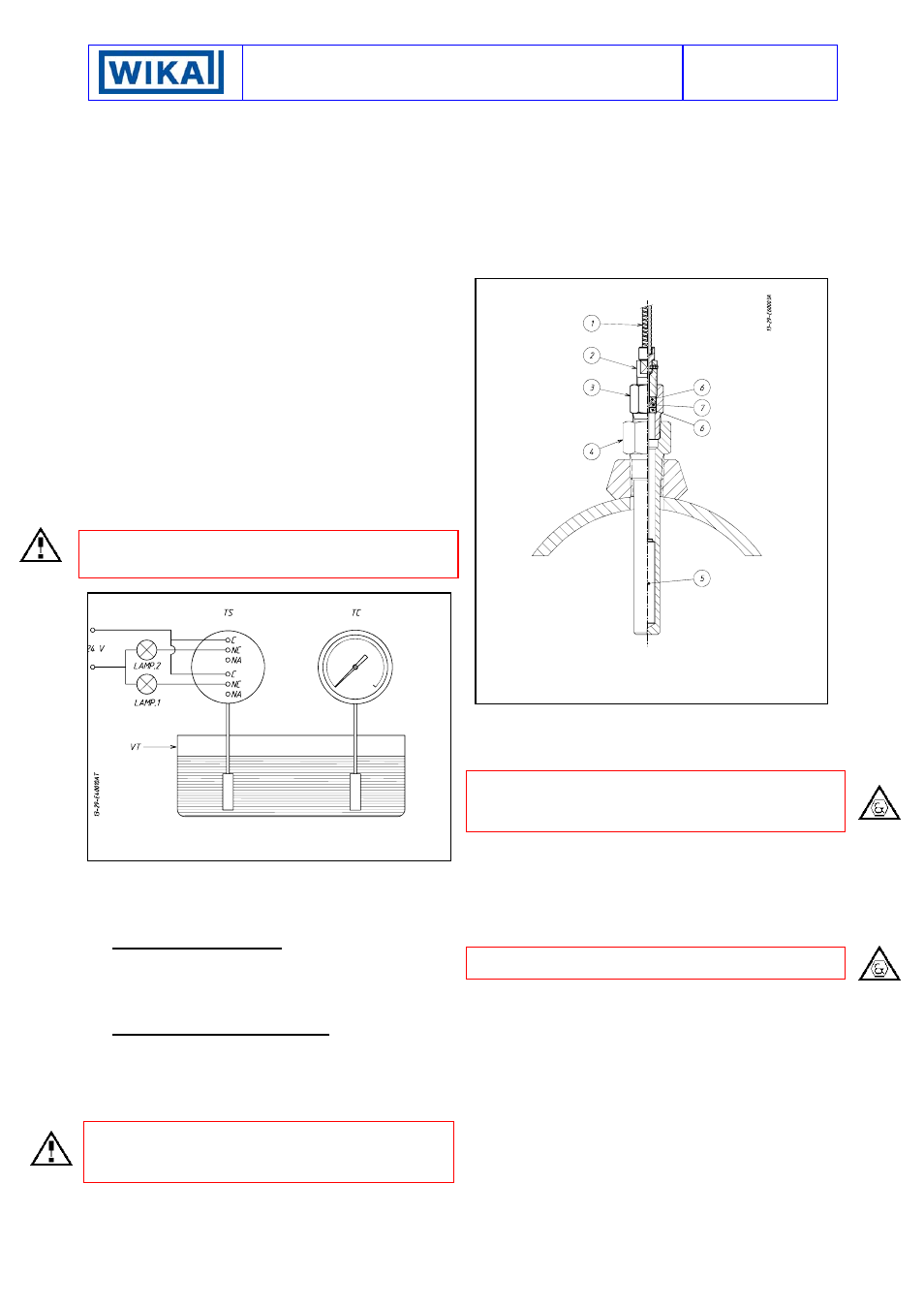

With reference to Fig. 5, unscrew union (3) from stuffing gland

(2) and slide it out from bulb (5).

Mount union (3) on thermowell (4) and tighten it with a proper

wrench. Spread on bulb (5) the special paste for better heat

transmission and insert it into thermowell (4).

Be sure that bulb reaches thermowell bottom. Insert into union

(3) PTFE washer (7) with relevant st. st. washers (4). Screw

stuffing gland (2) into union (3) taking care not to twist capillary

and its armor, then tighten it until PTFE washer presses against

capillary.

Fig. 5 -

Bulb mounting

1) Armored

capillary

2) Stuffing gland (SW 12)

3) Union

4) Thermowell

5) Bulb

6) St. st. washer

7) PTFE

washer

Run armored capillary avoiding too narrow bends, then staple it.

Excess capillary, if any, is to be rolled up around a 200 mm dia.

min., then firmly secured.

8.3

ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical connections

according to the applicable standards. In case of explosionproof

instruments (Series TXA) see also the Standards EN-60079-14

and EN-50281-1-2 .

The following mounting arrangements are possible.

8.3.1 MOUNTING WITH CABLE LOOSE (Fig. 10)

Run the cable so that it cannot be easily damaged (e.g. due to

too narrow bends, heat sources) and strain it.

Mount, if provided, the external ground device on the electrical

connection of the instrument. This device is to be threaded on,

while holding the electrical connection steady with a 27 mm

wrench on hex, until it reaches the bottom of the thread (Fig. 6).

The external ground screw is obligatory for explosionproof

constructions.