Instruction manual ni-401e – WIKA TWG User Manual

Page 5

INSTRUCTION MANUAL

NI-401E

Rev. 3 07/99

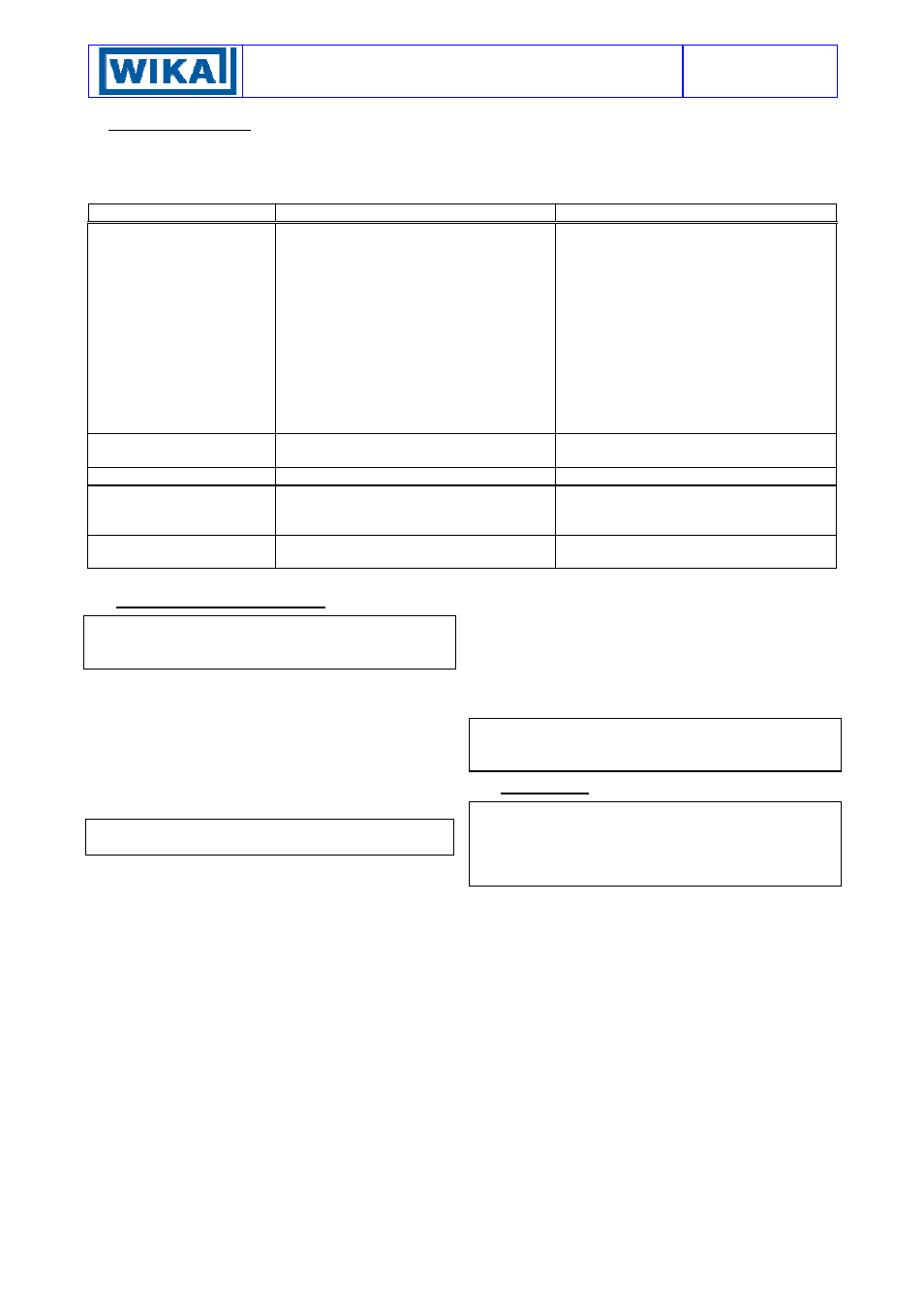

9 - TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our

workshop, especially for instruments with explosionproof certificate; this is to guarantee the user the total and

correct restoration of the product’s original characteristics.

MALFUNCTION PROBABLE

CAUSE

REMEDY

Set point shift

Wear of contact surfaces between

microswitch pin and sensing element tip.

Wear of contact surfaces between

microswitch cradle and adjustment

screw.

Possible encrustations or corrosions on

above listed surfaces.

Permanent deformation of the sensitive

element due to fatigue or non-tolerated

over-ranges.

Loss of filling fluid.

Recalibrate

Recalibrate

Clean surfaces and recalibrate. Check

housing tightness.

Recalibrate or replace the sensitive

element with another made of a suitable

material. If necessary apply a fluid

separator.

Replace sensing element with another

one of same type

Poor Repeatability

Assembling screws loosened.

Check terminal screws, microswitch,

electrical subassembly, fastening screws

Slow Response

Encrustations on bulb or thermowell

Check and clean encrustated surfaces

Failed or Undue Actuation

Microswitch contacts damaged

Electrical joints loosened

Electrical line interrupted, or short circuit

Replace microswitch

Check all electrical joints

Check state of electrical line

Undue Actuation

Accidental impacts or excessive

mechanical vibrations

Modify installation arrangement

10 - STOPPING AND DISMOUNTING

Before proceeding with these operations ensure that the

plant or machines have been put into the conditions

foreseen to allow these operations.

10.1 Remove the power supply (signal) from the electrical

line.

With reference to figure 5.

10.2 Loosen and remove the stuffing nat (2) being careful

not to bend the capillary and protective sheath (1).

10.3 Loosen and remove the fitting (3) then extract the bulb

(5) from the thermowell (4) holding it by the capillary tube

(1), without bending it.

Do not waste in to environment the process fluid if

polluting or harmful to people.

With reference to figures 6 and 7.

10.4 Unscrew the three piece joint (8) (electrical cable

tubing).

10.5 Remove the instrument cover and disconnect the

electrical cables from the terminal block and earth screws.

10.6 Remove the screws fixing the case to the panel (or

pipe) and remove the instrument, taking care to slide the

electrical conductors out from the case.

Replace the instrument cover. Insulate and protect the

conductors remaining on the plant. Temporarily plug the

thermowell.

11 - DEMOLITION

The instruments are mainly made of stainless steel and

aluminium and therefore, once the electrical parts have

been dismounted and the parts coming into contact with

fluids which could be harmful to people or the environment

have been properly dealt with, can be scrapped.