Instruction manual ni-401e – WIKA TWG User Manual

Page 2

INSTRUCTION MANUAL

NI-401E

Rev. 3 07/99

1 - GENERAL NOTES

1.1 FOREWORD

The wrong choice of a series or a model, as well as the

incorrect installation, lead to malfunction and reduce

instrument life. Failure to follow the indications given in this

manual can cause damage to the instrument, the

environment and persons.

1.2 ALLOWED OVERRANGE

Temperatures exceeding the working range can be

occasionally tolerated provided they remain within the

limits stated in the instrument features (vacuum or proof

temperature). Continuous temperatures exceeding the

working range can be applied to the instrument, provided

they are clearly stated in the instrument features. The

current and voltage values stated in the technical

specifications and ratings must not be exceeded.

Transitory overranges can have a destructive effect on the

switch.

1.3 MECHANICAL VIBRATIONS

Can generally lead to the wearing of some parts of the

instrument or cause false actuation. It is therefore

recommended that the instrument be installed in a place

where there are no vibrations. In cases where this is

impossible it is advisable to take measures to lessen the

effects (elastic supports, installation with the pin of the

microswitch positioned at right angles to the vibration

plane, etc.).

1.4 TEMPERATURE

Due to the temperature of both the environment and the

process fluid, the temperature of the instrument could

exceed the allowed limits (normally from -20° to +70°C).

Therefore, in case it does, suitable measures (protection

against heat radiation, heated cabinets) must be taken.

2 - OPERATING PRINCIPLE

The thermometric bulb is constituted by a rigid constant-

volume container. It is connected via capillary tubing to a

pressure measuring element (bourdon tube). This system

is filled with gas, and its absolute pressure is proportional

to absolute temperature (Charles’ law). As a consequence,

any change in bulb temperature causes a change in gas

pressure acting on sensible element, causing its free tip to

undergo an elastic deflection which is used to actuate one

or two electrical microswitches adjusted at prefixed set

point values.

3 - SET POINT REGULATION

3.1 Each microswitch is independent and can be

regulated by means of a screw (for adjustment) in such a

way that it actuates when the temperature reaches

(increasing or decreasing) the desired value (set point).

3.2 The instrument is usually supplied with the switches

set at 0°C or at the lowest setting range value if this is

higher than 0°C (factory calibration).

3.3 The instrument is supplied with an adhesive label

showing the set point calibration value. With factory

calibration the values are not indicated on the label, as

these are temporary and will be modified with the definitive

values.

3.4 Prior to installation the instrument must be calibrated

and the definitive calibration values written on the

adhesive label using a suitable indelible ink pen.

3.5 If the instrument has been expressly ordered with

specific calibration, it is a good rule to check the

calibration values stated on the adhesive label, prior to

installation.

3.6 The position of the adjustment screws is given in fig. 1.

3.7 The effect that the direction of rotation of the

adjustment screws is described on the adhesive label.

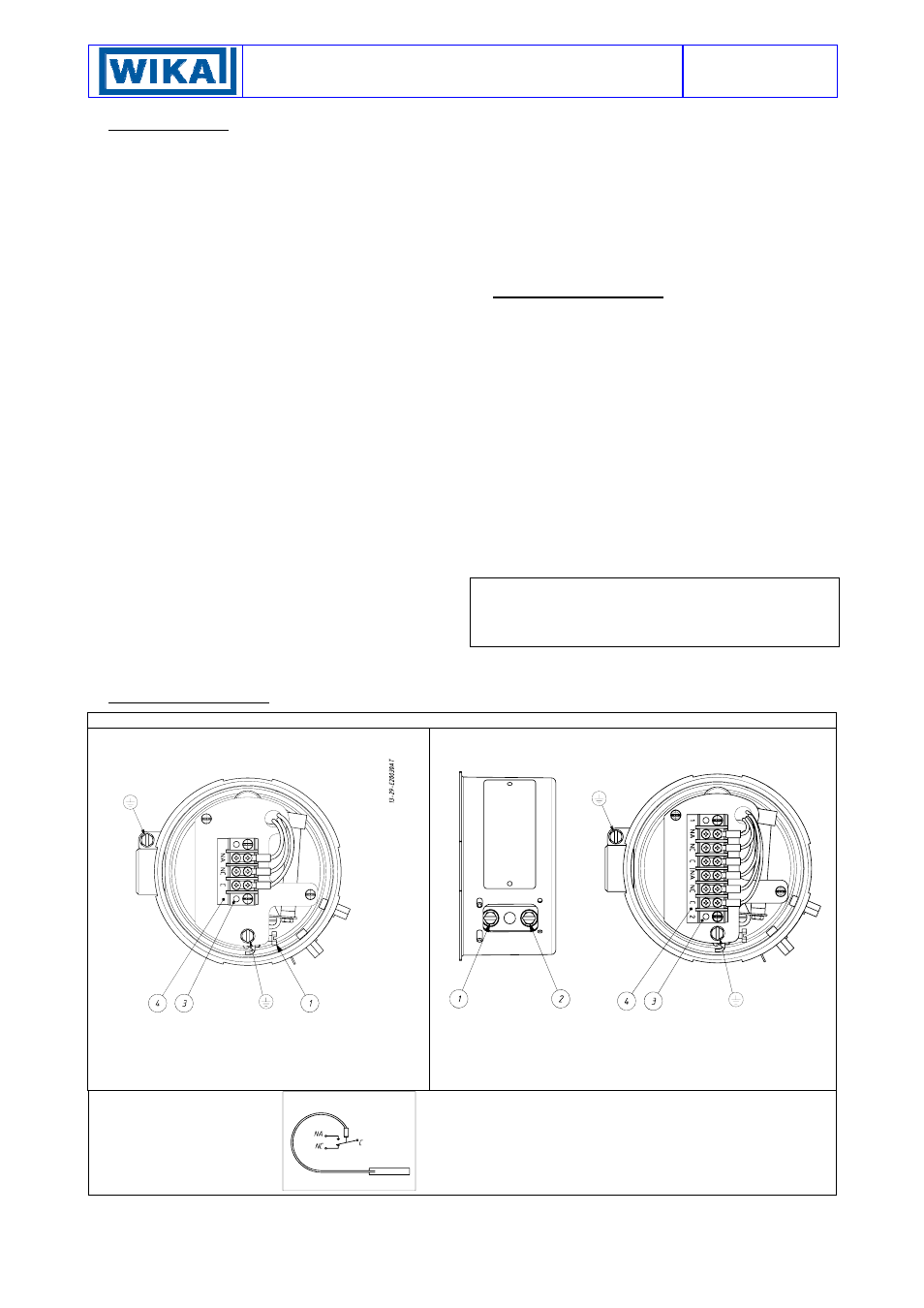

fig. 1 - Electrical connections and adjustment screws

One contact instruments

Two contact instruments

1 - Microswitch set point calibration screw

3 - Terminal block

4 - Electrical connection identification plate

1 – Microswitch 2 set point calibration screw

2 – Microswitch 1 set point calibration screw

3 – Terminal block

4 – Electrical connection identification plate

Designation of the contacts:

C - Common

NA - Normally Open

NC - Normally Closed

Microswitch electrical circuit: State of the contacts at initial temperature

range (when factory calibrated)