Instruction manual ni-401e – WIKA TWG User Manual

Page 3

INSTRUCTION MANUAL

NI-401E

Rev. 3 07/99

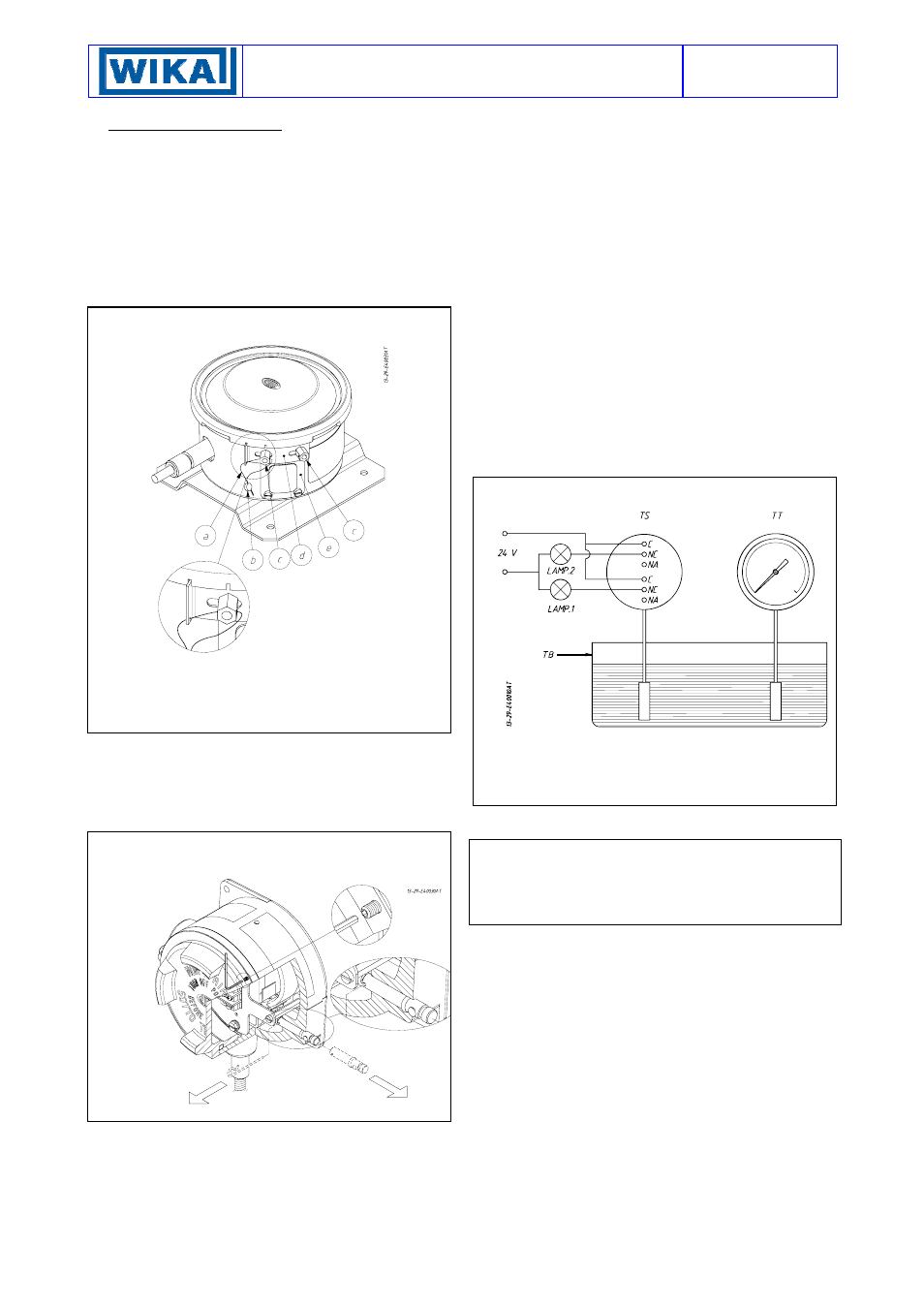

4 - SET POINT CALIBRATION

In order to proceed with the calibration and the periodical

functional verification of the instrument a suitable

calibration circuit (fig. 3) and an adequate heat source is

required.

4.1 PRELIMINARY OPERATIONS

4.1.1

Weatherproof temperature switches (Series

TWG) (Fig. 2)

Remove the blocking device fixed to the side of the

instrument case and the adjustment screw access plate.

Remove the cover be rotating it anticlockwise.

fig.

2

-

Weatherproof tempeature switch cover blocking

device and plumbing

a) Plumbing

wire

b) Plumbing

c) Blocking

nut

d) Blocking

bracket

e) Adjustment screws access plate

4.1.2

Explosionproof temperature switches (Series

TAG) (Fig. 3)

Loosen the locking headless screw situated on the cover

using a 1,5 hexagonal key then unscrew the cover.

Remove the internal blocking device inserted on the

closure plugs and slide out the plugs.

fig. 3 - Explosionproof temperature switch cover blocking

device

4.1.3

4.2 CALIBRATION CIRCUIT AND OPERATIONS

4.2.1 Prepare the control circuit as indicated in Fig. 4.

4.2.2 The warning lamps should be connected to contact 1

or 2 in the NO or NC position according to the required

contact action.

Connection of C and NO terminals

• If the circuit is open at the working temperature, the

switch closes the circuit as the temperature increases

when the desired value is reached.

• If the circuit is closed at the working temperature, the

switch opens the circuit as the temperature decreases

when the desired value is reached.

Connection of C and NC terminals

• If the circuit is closed at the working temperature, the

switch opens the circuit as the temperature increases

when the desired value is reached.

• If the circuit is open at the working temperature, the

switch closes the circuit as the temperature decreases

when the desired value is reached.

4.2.3 The test instrument should have a measurement

range approximately equal to or slightly wider than the

temperature switch range and should have an accuracy

consistent with the precision required to calibrate the set

point.

4.2.4 The temperature switch must be mounted in the

normal installation position, i.e. with the stem or capillary

outlet downwards.

fig. 4 - Calibration circuit

TS -

Temperature switch

TT -

Test thermometer

TB -

Thermostatic bath

4.2.5 Avoid forcing the microswitch by hand or with tools.

This could affect the instrument functioning.

CAUTION: If the switch is of the kind with adjustable dead

band (letter R in the contact codes) before proceeding with

the following operations (4.2.6-4.2.11) it is necessary to

proceed with the adjustment of the differential (see

attachment NI-705).

4.2.6 Increase the temperature in the circuit up to the

desired set point value for the first microswitch.

4.2.7 Use a wide bladed screwdriver, as indicated on the

adhesive label, until the relative lamp turns on (or turns

off).

- If the instrument is equipped with only one contact the

calibration is complete.

- If it is equipped with two contacts continue in the

following manner.

4.2.8 Vary the temperature until the desired set point value

for the second microswitch is reached.

4.2.9 Act on the adjustment screw of the second contact

as in point 4.2.7.

4.2.10 Repeat operations 4.2.6 and 4.2.7 on the first

contact, then operations 4.2.8 and 4.2.9 on the second

contact, until the required set point precision is obtained.

This is necessary due to the reciprocal influence which the

microswitches have with the sensitive element of the

instrument.