Instruction manual ni-223e – WIKA DE User Manual

Page 3

INSTRUCTION MANUAL

NI-223E

Rev. 2 11/02

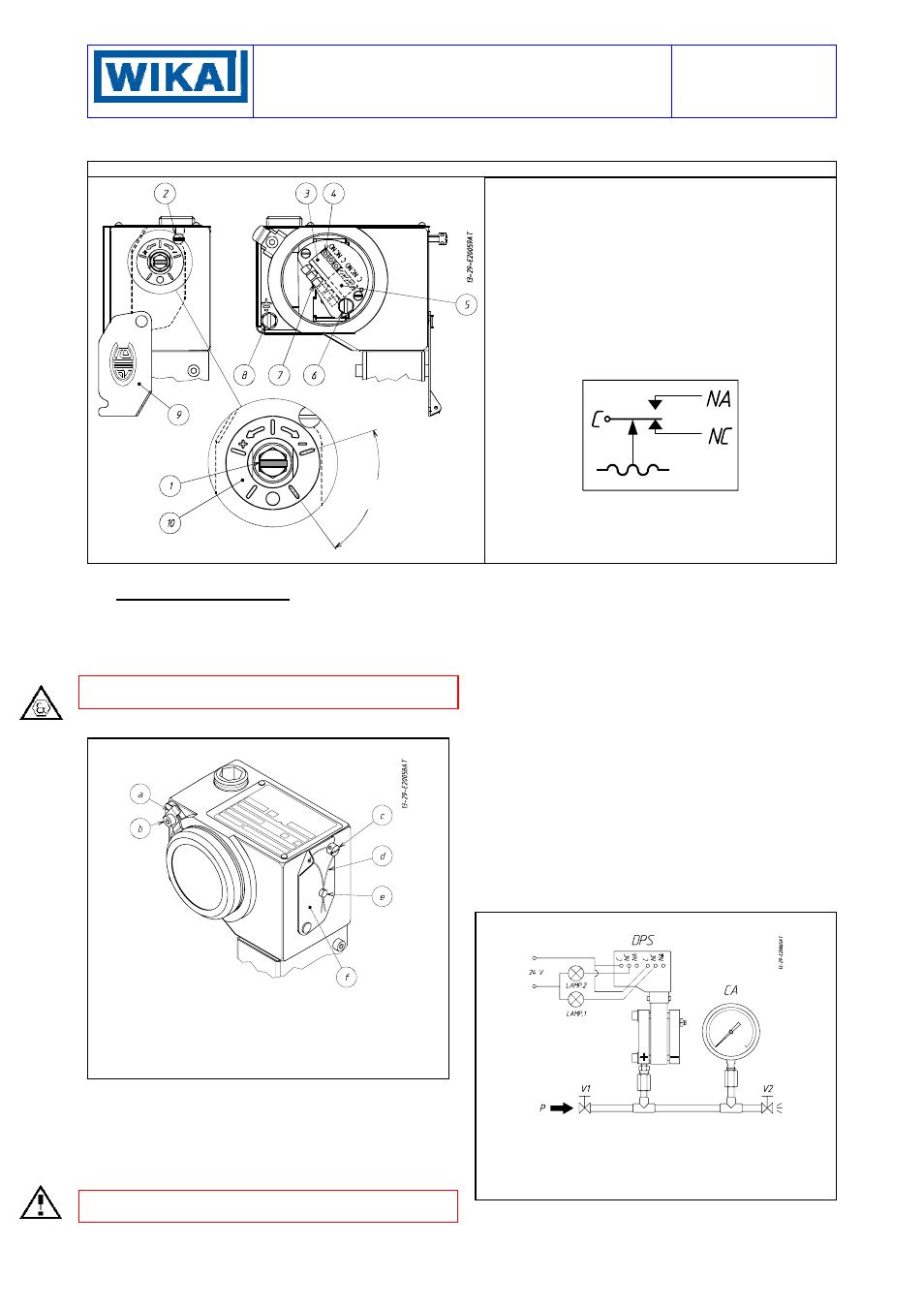

Fig. 2 -

Electrical connections and adjustament screws with one or two contacts instruments

1 - Adjustment screw

2 - Screw for fixing the adjustement

3 - Terminal block for the first microswitch

4 - Hole for test plug

5 - Terminal block for the first microswitch

6 - Internal earth screw

7 - Pre-insulated thimbles

8 - External earth screw

9 - Adjustment bush access plate

10 - Graduated dial

Microswitch electrical circuit.

State of the contacts at atmospheric pressure

Designation of the contacts:

C – Common

NA – Normaly open

NC – Normaly closed

5 - SET POINT CALIBRATION

In order to proceed with the calibration and the periodical func-

tional verification of the instrument a suitable calibration circuit

(fig.4) and an adequate pressure source is required.

5.1 PRELIMINARY OPERATIONS

CAUTION: do not open the cover of explosionproof pressure

switches (Series DE) when energized, in explosive atmospheres.

With reference to fig.3 unscrew the screw (b) until the blocking

device (a) can be turned 180°; then unscrew the cover.

Fig. 3 -

Cover blocking device and plumbing

a - Cover blocking device

b - Blocking screw

c - Screw blocking the adjustment bush access plate

d - Flexible steel wire

e - Plumbing

f - Adjustment bush access plate

5.2 CALIBRATION CIRCUIT AND OPERATIONS

Prepare the control circuit as indicated in Fig. 3 by connecting the

+ (or H) port to the pressure source and leaving the - (or L) port

open to the atmosphere.

The warning lamps should be connected to the contacts in the

NA or NC (NA = Normally Open NC = Normally Closed) position

according to the required contact action.

If the instrument is equipped with two microswitches, take into

account that they actuate simultaneously within rated tolerances.

The warning lamps can either be connected by means of a thim-

ble with a maximum diameter of 2.5 mm or by means of a test

plug with a diameter of 2 mm to be inserted in the appropriate

holes situated frontally beside the terminal screw (see fig.2).

Connection of C and NO terminals

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure increases when the desired values is

reached (MAKE on Raise).

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure decreases when the desired value is

reached (BREAK on Fall).

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch opens

the circuit as the pressure increases when the desired value is

reached (BREAK on Raise).

• If the circuit is open at the working pressure, the switch closes

the circuit as the pressure decreases when the desired value is

reached (MAKE on Fall).

The test instrument should have a measurement range approxi-

mately equal to or slightly wider than the differential pressure

switch range and should have an accuracy consistent with the

precision required to calibrate the set point.

The differential pressure switch must be mounted in the normal

installation position, i.e. with the pressure connections down-

wards.

Fig. 4 -

Calibration circuit

DPS Differential pressure switches

Test fluid:

CA

Test gauge

air for

P

≤ 10 bar

V1

Inlet valve

water for P > 10 bar

V2 Discharge

valve

P Pressure

source

Avoid forcing the microswitch by hand or with tools. This could af-

fect the instrument functioning.

With reference to fig.3, clear the access to the adjustment bush

by loosening the screw (c) which holds the access plate (f).

≅ 5% span