Instruction manual ni-209e – WIKA DA10 User Manual

Page 5

INSTRUCTION MANUAL

NI-209E

Rev. 4 12/02

6.3 ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical

connections according to the applicable standards. In

case of explosionproof instruments (Series DA) see also

the Standard EN-60079-14. If the electrical connection

is carried out in a protected tube, it shall be made so

that condensate is prevented from entering instrument

enclosure.

The arrangement shown in figure 7 and 8 is therefore

recommended.

CAUTION:

fittings used for the electrical connection of

the pressure switch Series DA (explosionproof) shall be

certified to Standards EN 50014 and 50018, and shall

guarantee instrument degree of protection (IP65).

Check that there is no power in the lines. Remove the

cover and carry out the cabling and connections to the

terminal block (see Fig. 2). Flexible cables with a

maximum section of 1.2 mm

2

(16AWG) are

recommended using pre-insulated fork thimbles. Do not

touch the adjustment screws and do not bend the

elastic microswitch supports in order to prevent the

instrument calibration being altered. Ensure that no

deposits or wire ends remain inside the case.

As soon as connection steps are completed, mount the

cover on and make sure it is tight and blocked See Fig.

3 and 4.

6.4

SPECIAL NOTE FOR INSTALLATION OF

CATEGORY 1/2 G PRESSURE SWITCHES

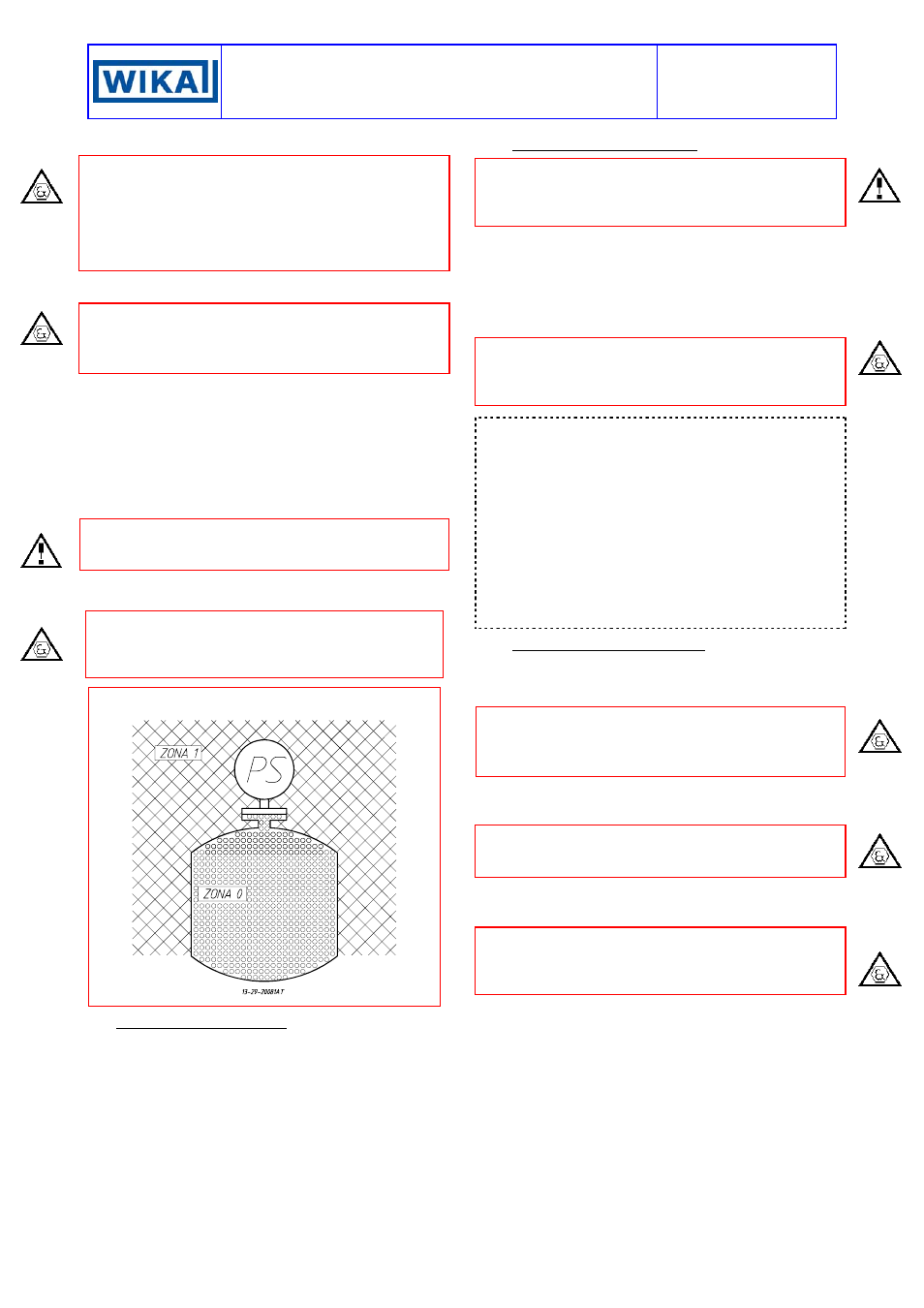

Explosionproof pressure switches (Series DA) can be

installed on processes requiring apparatus of group II

category 1 in an ambient requiring apparatus of group II

category 2 (see Fig. 6).

Fig. 6 -

Installation of Group II Cat. 1 / 2 G instruments

7. INSTRUMENT

PLUMBING

Weatherproof pressure switches (Series DW)

The plumbing, aimed as a guarantee against possible

tampering of the calibration and electrical connections,

can be carried out using a flexible steel wire (a) inserted

into the holes in the locking nut (c) and the bracket (d)

provided for this purpose (see Fig. 3).

Explosionproof pressure switches (Series DA)

Plumbing is not necessary as the cover is blocked with a

headless screw, the closure plugs of the adjustment

screw access holes are blocked by means of the

internal blocking device and the instrument does not

have to be opened when installed (see Fig. 4).

8. PUTTING INTO OPERATION

As the signal transmitted by the instrument is used in a

complex system, it is necessary that the means of

putting it into operation are established by personnel in

charge of the plant

.

The instrument comes into operation as soon as the root

valves are opened and then, afterwards, the service

valve attached to the instrument + inlet pipe is opened,

the by-pass valve closed and the service valve attached

to the instrument - inlet pipe is opened. Any possible

drainage of the connection tubing can be carried out by

opening the drains positioned on the instrument.

In case of explosionproof instruments (Series DA), initial

inspections are to be carried out according to customer

procedures and at least in accordance with Standard

EN-60079-17.

NOTE: if the instrument is used for level control in

tanks under pressure and is installed according to the

diagram in Fig. 10 proceed as follows:

Close the root valves V1 and V2 open the valves V3 V4

V5 (the service and by-pass valves). Fill with the

process fluid, from plug SB positioned on the seal pot B,

bleeding air from the plug S positioned on the seal pot

near the V2 valve. Then close S and top up the liquid in

B. Remove air from the breather plug S+ and S-

positioned on the instrument, topping up the liquid in B.

Close the plug SB and the by-pass valve V5 and open

the root valves V1 and V2. The instrument is ready for

use.

9. FUNCTIONAL

VERIFICATION

This will be carried out according to the Client’s control

procedures. Series DW instruments can be verified on

the plant if installed as illustrated in Fig. 7 or 8.

The instruments Series DA may be checked on site only

if apparatus suitable for explosive atmospheres are

used and provided that the electric line is not

energized.

If this is not the case it is necessary to stop operation,

dismount by means of the three piece joints and carry

out the verification in a test room.

CAUTION: do not open the cover of explosionproof

pressure switches (Series DA) when energized, in

explosive atmospheres.

Verification consists in checking the calibration value

and possibly regulating the adjustment screw (see

par.5).

In case of explosionproof instruments (Series DA),

inspections of the electrical installation are to be carried

out also according to customer procedures and at least

in accordance with Standard EN-60079-17.