Gb 6. commissioning, operation – WIKA OT-1 User Manual

Page 10

10

WIKA operating instructions OEM pressure transmitter, model OT-1

2127027.02 09/2013 GB/D/F/E

GB

6. Commissioning, operation

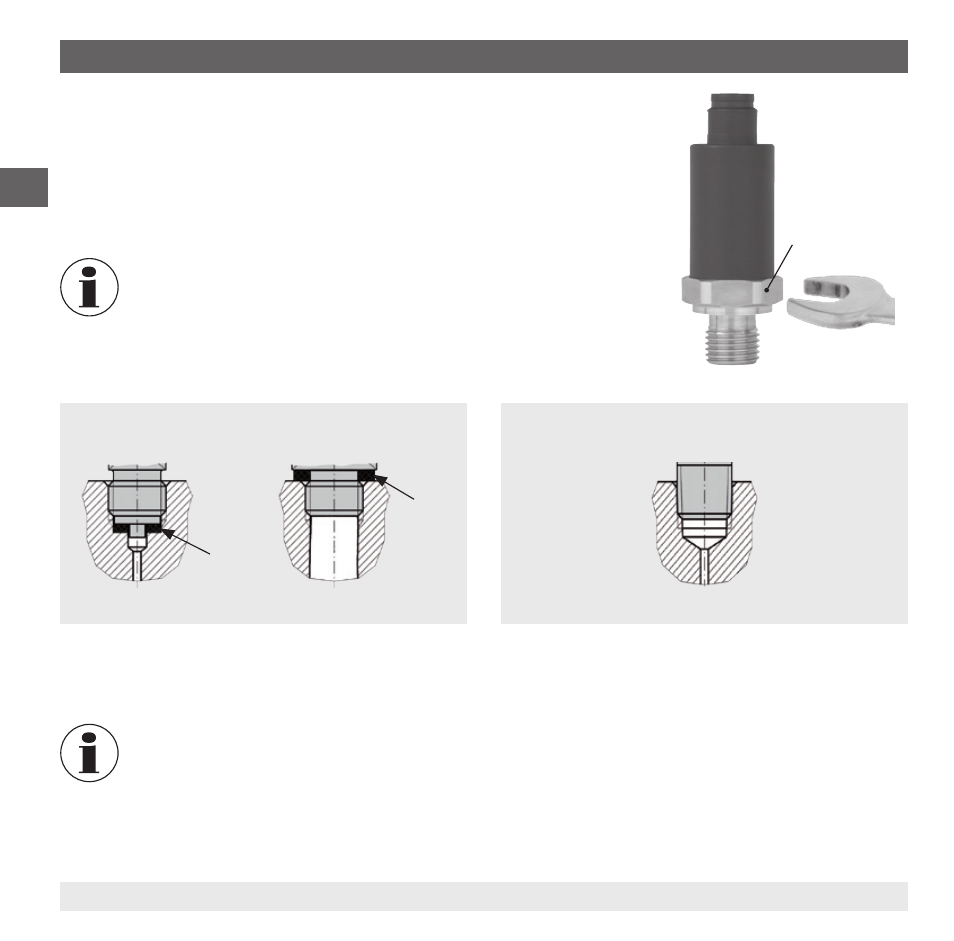

Correct sealing of the process connections with parallel

threads at the sealing face

must be made using suita-

ble flat gaskets, sealing rings or WIKA profile sealings.

For sealing process connections with tapered threads,

the sealing must be made in the threads using additional

sealing material, e.g. PTFE tape (EN 837-2).

6.1 Mechanical mounting

■

The sealing faces at the instrument have to be undamaged and clean.

■

When screwing the instrument in, the force required to do this must not be

applied through the case, but only through the spanner flats provided for this

purpose, and using a suitable tool.

■

When screwing in, do not cross the threads.

For information on tapped holes and welding sockets, see Technical

information IN 00.14 at www.wika.com.

Sealing the process connection

For further information on seals see WIKA data sheet AC 09.08 or at www.wika.com.

Spanner flats

per EN 837

per DIN 3852-E

NPT, R and PT

Parallel threads

Tapered threads