8 commissioning, 9 operation, 10 maintenance and care – Festo Линейный привод с датчиком перемещения DFPI User Manual

Page 4: 11 disassembly and repair, 12 troubleshooting, 13 technical data

8

Commissioning

The product is ready for operation as soon as it is installed and connected.

• Make sure that the operating conditions lie within the permitted ranges (tech-

nical data

chapter 13).

• Make sure that a slide gate (process valve) attached to the linear drive can be

positioned without hindrance.

• If necessary, adjust the linear drive adapter attached to the piston rod. This

setting serves to optimise the opening or closing reaction of the connected

process valve or penstock valve.

• Slowly pressurise the linear drive.

For slow start-up pressurisation use soft-start valve type HEL.

• At first, select a slow travel speed.

9

Operation

Warning

Fast moving parts can cause injury to people in the vicinity of the DFPI.

• Make sure that, in the positioning range:

– Nobody can place his/her hand in the path of moving components (e.g. by

providing a protective guard).

– There are no foreign objects in the path of the moving components.

It should not be possible to touch the DFPI until the mass has come to a com-

plete rest.

10

Maintenance and care

If used as intended in the operating instructions, the device will be maintenance-

free.

11

Disassembly and repair

Make sure that the following energy sources are switched off:

– electrical power supply

– compressed air supply.

1. Remove the slide gate from the piston rod.

2. Remove the screws on the flange of the processing valve or penstock valve.

3. Remove the drive (if necessary including mounting adapter and coupling exten-

sion).

Recommendation: Send the product to our repair service. This way, the required

fine tuning and tests will be taken into special consideration.

Information about spare parts and accessories

www.festo.com/spareparts.

12

Troubleshooting

Malfunction

Possible cause

Remedy

Piston rod does not move in

the desired direction

Compressed air tubes inter-

changed

Correct the tubing connection

Displacement encoder cable

incorrectly connected at posi-

tioning controller or DFPI (e.g.

connections at pin 1 and pin 3

interchanged).

Correct the connection

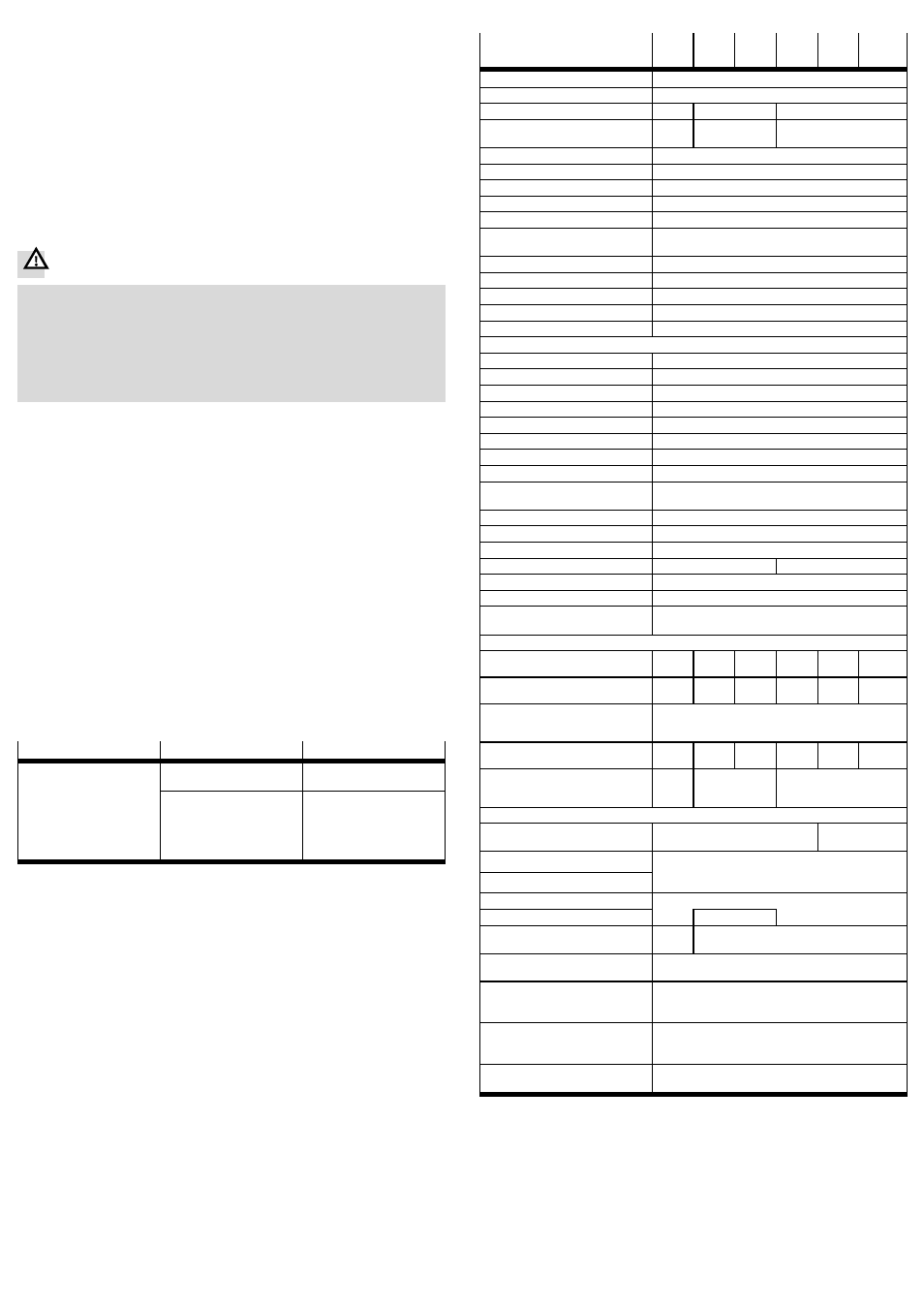

Fig. 11

13

Technical data

DFPI-...-...-ND2P-E-P-G2

-100-

...

-125-

...

-160-

...

-200-

...

-250-

...

-320-

...

Based on standard

DIN 3358

Type of mounting

on flange in accordance with DIN 3358

Flange hole pattern

F07

F10

F10, F14

Width across flats, spanner

flat on the piston rod

22

27

36

Design

Piston rod, cylinder barrel

Cushioning

No cushioning

Mounting position

Any

Mode of operation

Double-acting

Position sensing

With integrated displacement encoder

Measuring principle of displacement

encoder

Potentiometer

Operating voltage range

[V DC]

0 … 15

Max. operating voltage

[V DC]

15

Independent linearity

[% FS]

±0.04

Hysteresis

[mm]

0.33

Repetition accuracy

[mm]

±0.12

Resistance value of displacement encoder (on the T.E.P.) dependent on the stroke length

1)

–

š 290 mm

[kΩ]

5

–

, 290 mm to 590 mm

[kΩ]

10

–

, 590 mm to 990 mm

[kΩ]

20

Electrical connection

3-pin; straight plug; screw terminal

Pneumatic connection

For tubing outside

∅ 8 mm

Operating pressure

[bar]

3 … 8

Nominal operating pressure

[bar]

6

Operating medium

Compressed air in accordance with ISO 8573-1:2010 [7:4:4]

Note on the operating medium

Operation with lubricated medium possible (in which case

lubricated operation will always be required)

Max. cable length

[m]

30

Protection class - in mounted status

IP65, IP67, IP68, IP69K, NEMA 4

Stroke

[mm]

40 … 990

Stroke reserve

[mm]

3

4

Ambient temperature

[°C]

–20 … +60

Relative air humidity

[%]

0 ... 100 condensing

Use in exterior

C1 – weather-protected areas in accordance with

IEC 60654

Product weight

– Basic weight with 0 mm

stroke

[g]

3476

5530

6529

13 946

22 569

35 359

– Additional weight per

10 mm stroke

[g]

80

145

159

187

325

399

– Additional weight

of displacement encoder

per 10 mm

[g]

2

– Moving mass

with 0 mm stroke

[g]

1228

1944

2250

4722

7059

11417

– Additional weight

of moving mass

per 10 mm stroke

[g]

27

52

87

Materials

– Cylinder barrel

Anodised wrought aluminium alloy

High-alloy

stainless steel

– Cap (end cap)

Anodised wrought aluminium alloy or

Anodised and painted wrought aluminium alloy or

Cast aluminium painted

– Bottom cap (bearing cap)

– Piston rod

High-alloy stainless steel

– Screws

Steel

2)

– Seals

NBR,

PU

NBR

Note on materials

Contains PWIS (paint-wetting impairment substances),

RoHS-compliant

Vibration resistance

in accordance with DIN/IEC 68,

Part 2-6

0.35 mm path at 10 ... 60 Hz;

5 g acceleration at 60 ... 150 Hz

Continuous shock resistance

in accordance with DIN/IEC 68,

Part 2-82

±15 g at 6 ms duration;

1000 shocks per direction

CE certification (see declaration of

conformity

www.festo.com)

in accordance with EU Explosion Protection Directive

(ATEX)

3)

1)

T.E.P. = theoretical electrical path

2)

Steel and high-alloy stainless steel

3)

Certification-specific special documentation must be considered (

www.festo.com/sp).

Fig. 12