Example: pneumatic control control – Festo Устройство подачи BV User Manual

Page 2

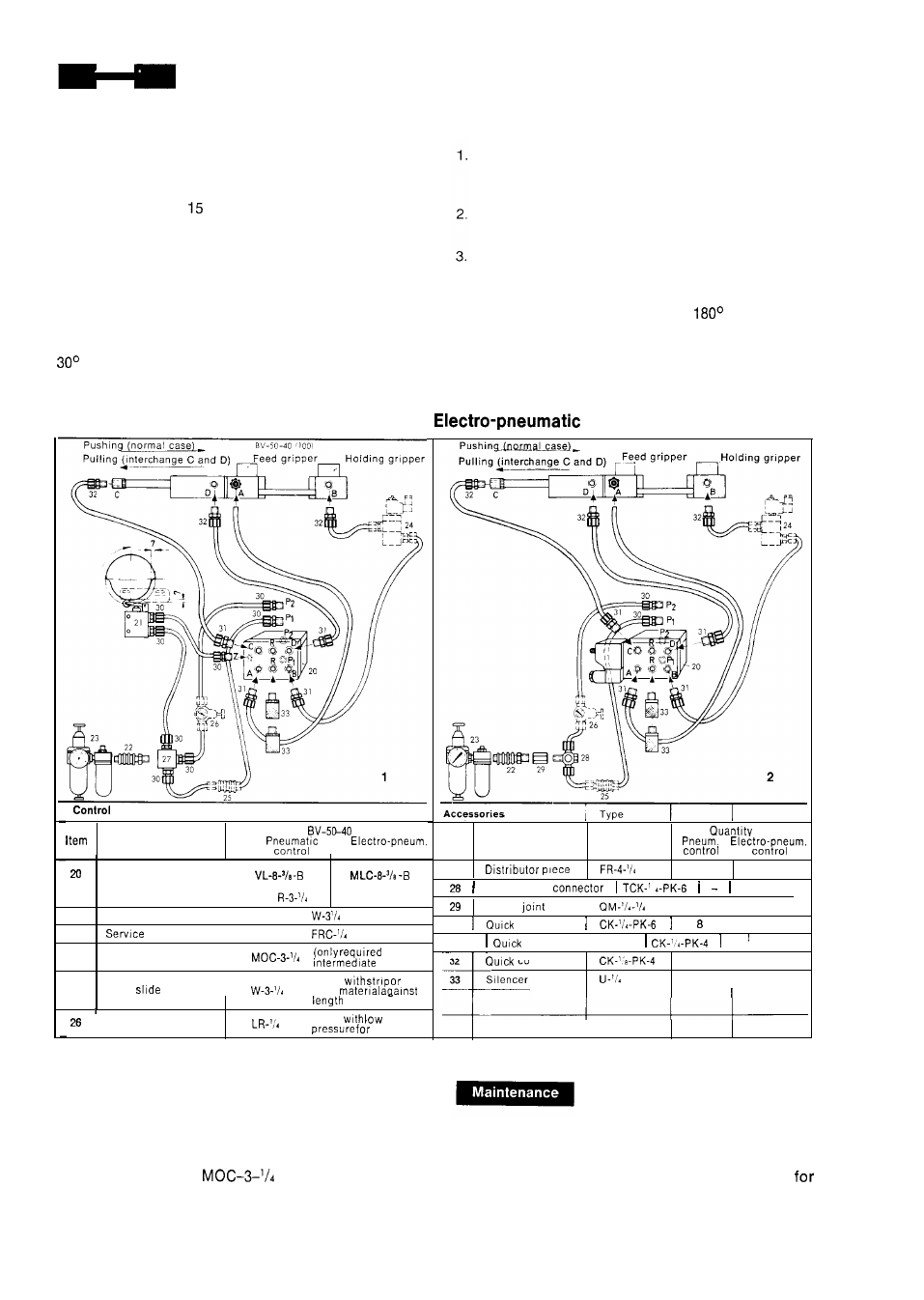

To obtain the optimum cycling frequency, the control

line between valves 20 and 21 should not exceed

two metres in the pneumatic control (Fig. I). The

control signal for valve 20 can be obtained linearly or

rotary as required. With linear pick-up, an adjustable

control rail must be mounted on the press ram. With

press strokes over

mm, only rotary signal pick-up

is possible.

Reverse control (if feed unit is to operate in the

opposing direction)

Reversal of the feed direction and opposite start-

ing position of the slide: interchange connections

C and D.

In general, the rotary type of signal pick-up is to be

preferred. This usually allows one to avoid resetting

of the control rail if tools are changed.

With both types of control, the timing of the pulse

output for the feed should be selected such that the

rams have wiped off and the tape is freely located in

the tool. The feed should be completed no later than

after upper dead centre.

Reversal of feed direction with same starting posi-

tion of the slide: interchange connections A and B.

Reversed starting position of the slide with same

feed direction: interchange connections A and B

and also C and D on the feed unit housing.

slackened.

The grippers can be shifted through

such that the

opening is on the opposite side. To do this, the

socket head cap screws (7, front side) must be

Example:

Pneumatic control

control

elements

N a m e

(100)

c o n t r o l

A i r - o p e r a t e d v a l v e

s o l e n o i d v a l v e

21

R o l l e r l e v e r v a l v e

22

H a n d s l i d e v a l v e

23

u n i t

24

S o l e n o i d v a l v e

w i t h

e x h a u s t )

25

H a n d

valve

( o n l y

t a p e

s t o p )

P r e s s u r e r e g u l a t o r

( o n l y

feed)

Tools with catch pins

Where cycling rate and ram stroke permit, it is pos-

sible to momentarily exhaust the holding grippers

with tools having catch pins (locating pin, pilots). A

solenoid valve type

(24) fitted in line B

and operated by means of a cam disc and a limit

switch exhausts the holding gripper as soon as the

catch pin is inserted in order that the strip can be

centered.

The solenoid valve (Fig. 2. item 20) obtains its reversal

pulse from an electrical limit switch.

Item

N a m e

27

1

Quick

1

Socket

1

30

c o n n e c t o r

2

31 connector

4 4

c o n n e c t o r

3

3

2

2

A service unit type FRC must befitted on the upstream

side of the entire control system. With this unit, the

compressed air is cleaned, regulated to constant

pressure (6 bar), and provided with a fine oil mist

lubricating purposes. The bearing bushes of the feed

brace must be lubricated from time to time by means

of lubricating nipple (II).