Enter the over temperature limit, Press the reset button, Enter the setpoint – Chemglass CG-1972-65 User Manual

Page 4

4

Section 1: Quick Operating Instructions

The three steps below are the basics of using your temperature controller. The User’s Manual is a reference that

explains the controller more fully as well as some of its more sophisticated features. It’s recommended that new

users unfamiliar with process controllers read the entire manual carefully. The controller is preprogrammed

for use with heating mantles fitted to round bottomed flasks running “typical” organic reactions (i.e., non-

polymeric reactions in solvents such as THF, toluene, DMF, etc.). If the controller is used with this type of

reaction, the 3 steps below will help you get started.

To use heaters other than heating mantles:

See Section 2.

Do not use the controller to heat oil baths:

See Section 3.2.

For polymer synthesis, atypical, expensive, or safety critical reactions:

See Appendix I

1

Enter the Over

Temperature Limit.

This meter, labeled “Limit Controller”,

is the back-up meter for the setpoint

controller. Set this meter about 5

o

C

higher than the temperature entered

into the Setpoint Controller in Step 5 If

the reaction reaches this temperature

limit for any reason, heating is

automatically stopped until being

manually reset. See Section 3.3.

*

8 0. 0

Limit

Controller

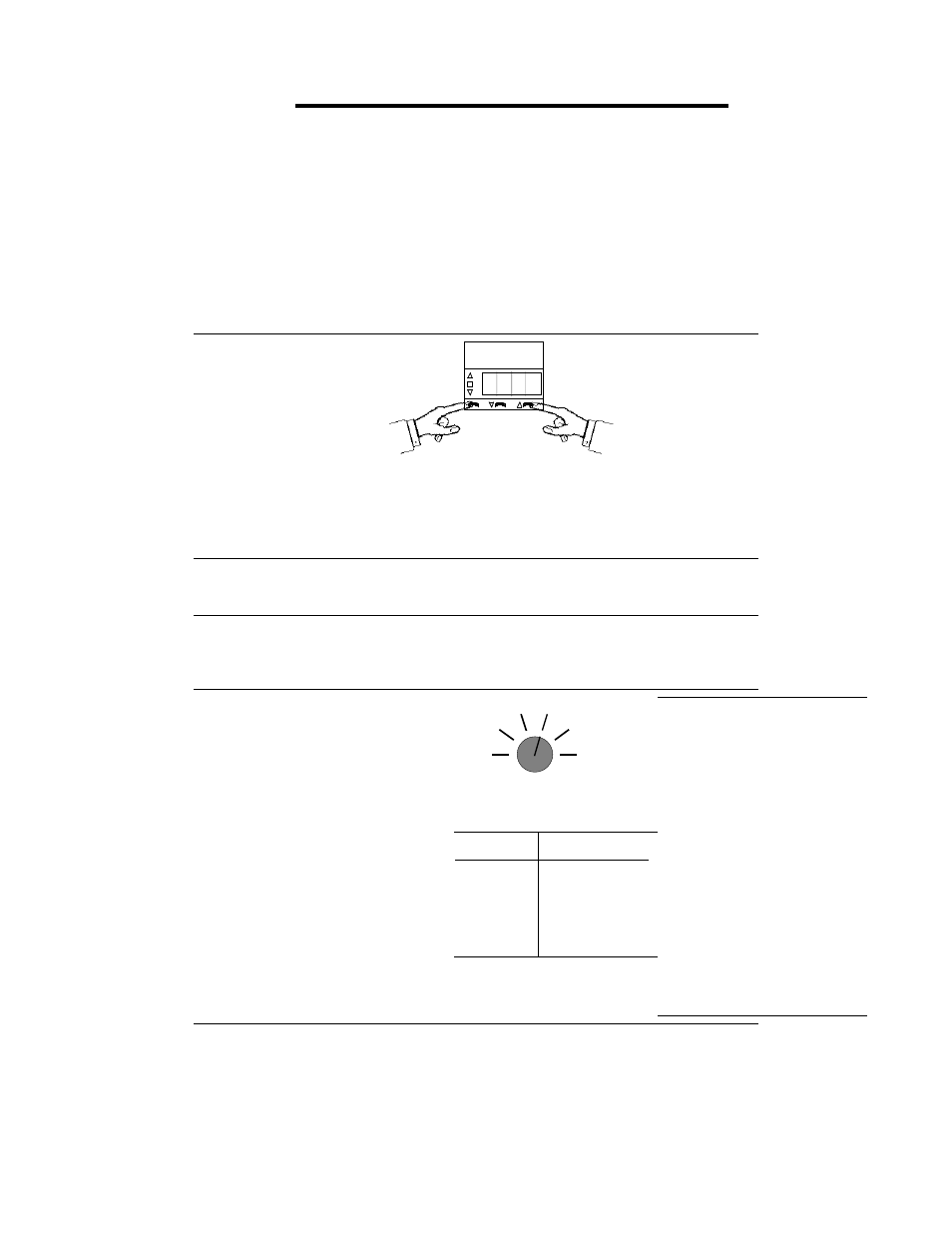

To enter a temperature into either

of the digital meters, hold the *

button and simultaneously press

the ▲ key to increase or the ▼ key

to decrease the setpoint. The

setpoint can be seen at anytime by

holding in the * button. The

setpoint appears as a blinking

number in the display.

2

Press the Reset Button.

The reset button resets the over temperature circuit and prepares the controller

for use. The probe temperature must be below the temperature of the limit controller or the circuit will not reset.

3

Place the thermocouple in the solution being heated.

Place at least the first 1/4” of the

thermocouple directly in the solution being heated. Thermocouples can be bent without harming them. If you’re

heating a corrosive liquid, use Teflon coated thermocouples. If you are heating a sealed reaction, see Section 4.2.

4

Set the power level switch to the

volume of solution being heated

(not the size of the flask being used). The

power level switch can be thought of as a

solid state variac. Volume ranges are printed

above this switch as a guide to select the

correct power level since it’s easier to guess

the volume being heated than the appropriate

“percent power” to apply to a heater. ‘Heat

Off’ turns off the heater so the controller

displays temperature only. All new users

should read Section 3.5.

1-10 ml

10-100 ml 50-500 ml

300 ml-2 L

> 2 L

Output

Power Level

Heat

Off

A power

is equivalent to

setting of..... a variac setting of:

1-10

ml

3%

10-100 ml

10%

50-500 ml

25%

300 ml - 2 L

50%

> 2 L

100%

TIP: Because the power switch

acts like a variac, if the reaction

is heating too slowly or you need

more power (e.g., heating to high

temperatures), give the heater

more power by turning the

power level up one setting. If

the reaction needs less power

than normal (e.g., heating to low

temperatures (<60

o

C) or the

temperature overshoots the set

point excessively, turn the power

down one setting. DO NOT set

the power switch on a setting too

high initially to heat the reaction

quickly and then lower it to the

correct setting, this degrades

heating performance.

5

Enter the setpoint

(i.e., the desired reaction temperature) into the setpoint controller by holding in the *

button and simultaneously pressing the ▲ key to increase or the ▼ key to decrease the setpoint. The setpoint can be

seen at anytime by holding in the * button, the setpoint appears as a blinking number in the display.