Chemglass CG-1972-65 User Manual

Page 11

11

3.3

Setting the Controller for Safe Operation. Two completely separate controllers are contained in the

J-KEM Model HCC and it’s important to understand what each controller does in order to take full

advantage of the Model HCC’s safety benefits.

8 0. 0

o

C

*

Setpoint

Controller

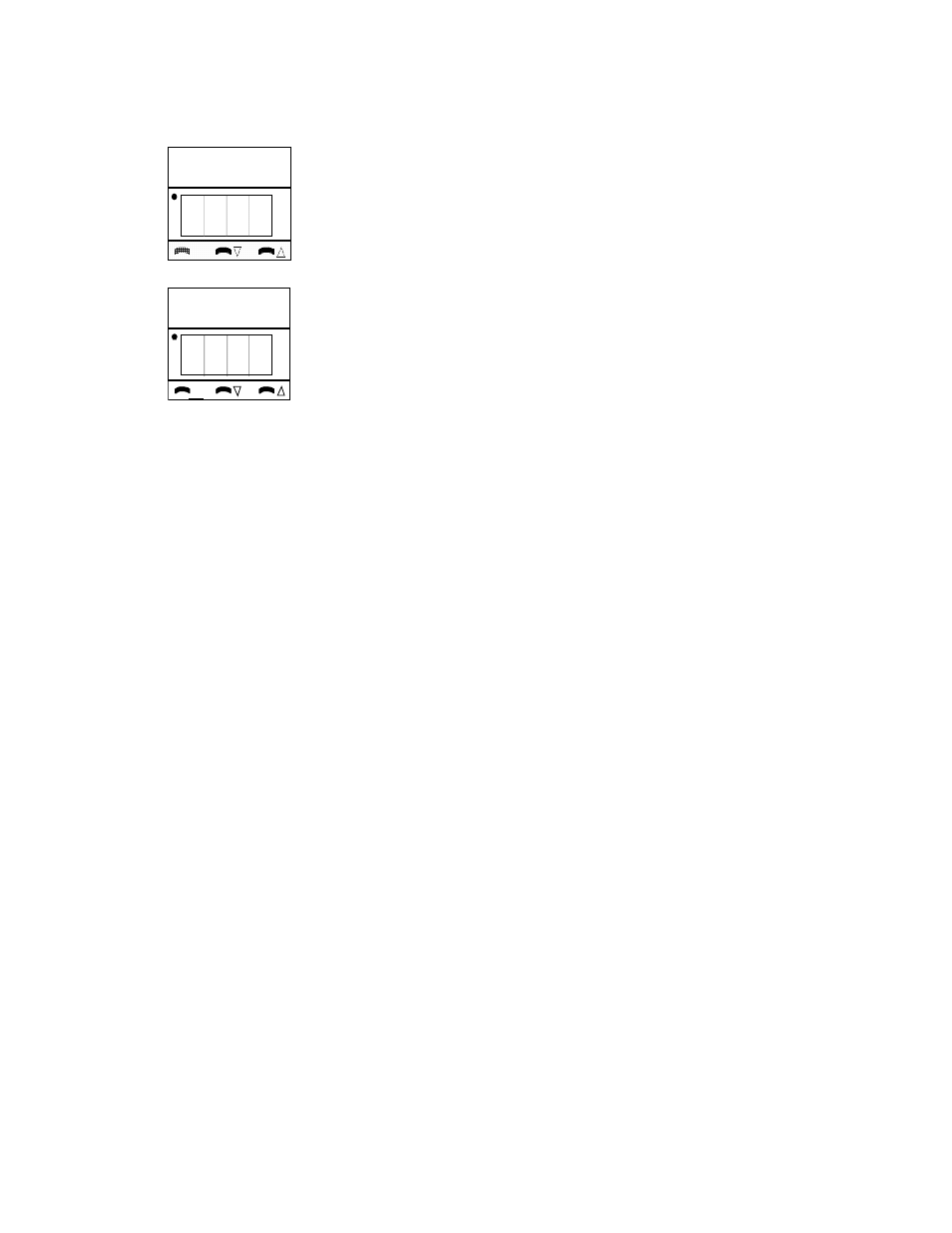

The meter on the far left, labeled Setpoint Controller is the main process controller and

is responsible for all aspects of temperature control including, heating, cooling,

maintaining the temperature, tuning, etc. The desired solution or process temperature

is entered into this controller.

8 0. 0

o

C

*

Limit

Controller

The meter on the right, labeled Limit Controller has no influence on the heating

process, which is under the complete control of the meter on the left. The purpose of

this unit is to monitor the temperature of the reaction or process and take control if a

heating error occurs thus acting as a watchdog or backup unit to the setpoint

controller. In normal use, a temperature is entered into this controller, which is several

degrees (≈ 5

o

C) above the temperature entered into the setpoint controller. If the

process heats to the temperature entered into the limit controller, power is physically

disconnected from outlets 8 and remains disconnected until the controller is manually

reset.

Setting up an experiment with the Model HCC is quite simple. Place the dual element

thermocouple in the process to be heated and turn the controller on. Enter the desired temperature into

the setpoint controller (i.e., the meter on the left) (for example 80

o

C) then a slightly higher temperature

into the limit controller (for example 85

o

C). Press the reset button (9). The setpoint controller begins to

heat the process to 80

o

C where it will maintain it indefinitely. The only time the limit controller comes

into play is if, for whatever reason, the temperature of the process rises to 85

o

C at which point power is

removed from outlets 8. Power remains disconnected until being manually reset. The operation of the

limit controller can be verified at any time by entering a temperature lower than ambient which should

activate the over temperature protection circuit indicated by light 6 coming on.

The Model HCC derives its’ unique safety advantages from it’s design in which the temperature

sensing ability and action of the two controllers are completely independent of the other. By considering

the way the controller responds to different types of heating failures demonstrates the safety benefits of

this construction. If the limit controller fails closed, the over temperature protection circuit is activated

disconnecting all power to the heater. If it fails open, this has no effect on the temperature regulation of

the setpoint controller, which continues to maintain the desired temperature of the process. If the setpoint

controller fails closed (The most dangerous failure mode. (i.e. uncontrolled full power to the heater)) The

limit controller activates the over temperature protection circuit permanently disconnecting all power to

the heater. If the setpoint controller fails open the process simply cools to room temperature. Since each

controller has its’ own thermocouple a failure with either thermocouple results in the same scenarios as

above. The Model HCC provides complete, 100% redundant control of the heating process for maximum

safety of unattended operations.