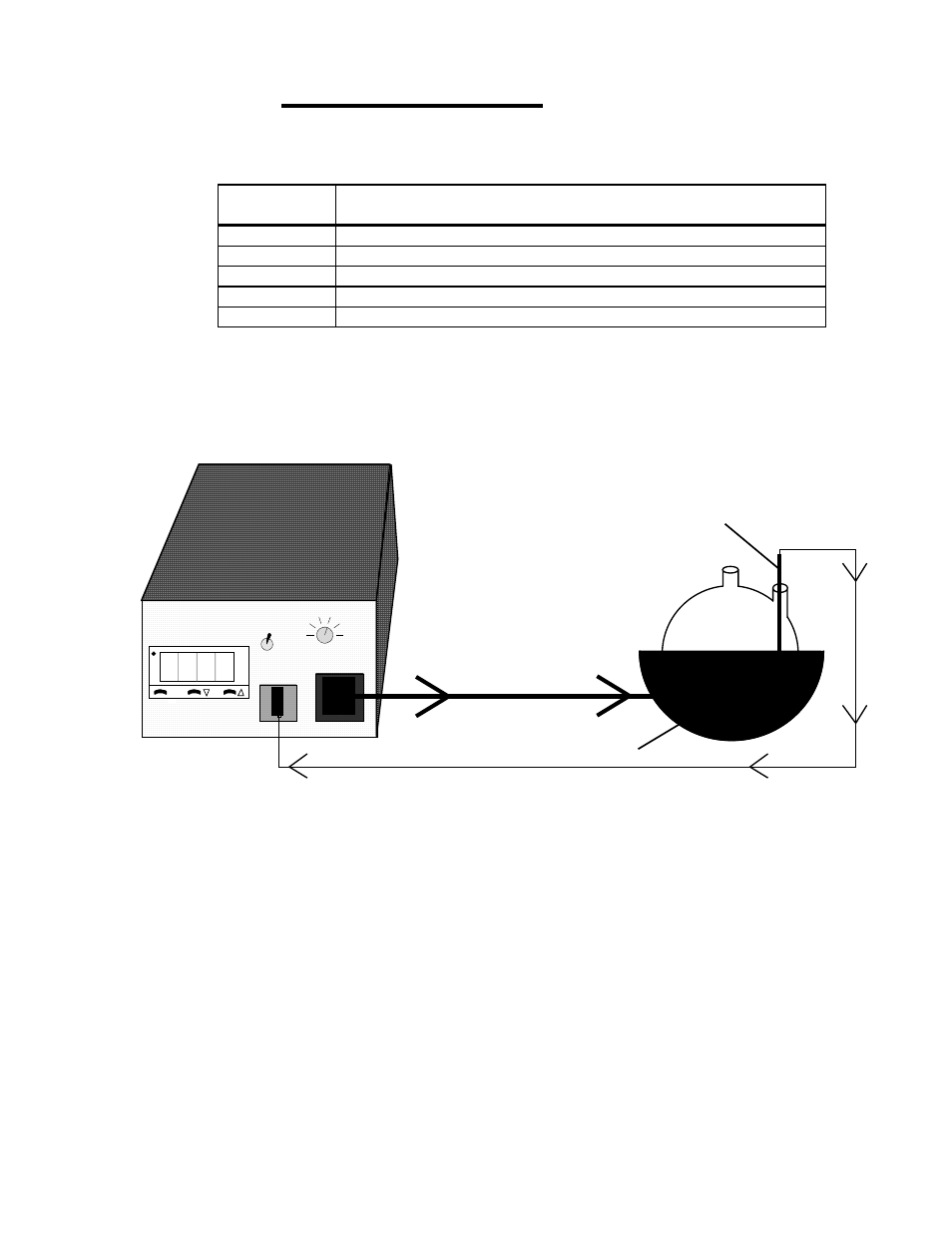

120 vac power to heater, Figure 2 – Chemglass CG-1972-65 User Manual

Page 21

21

Section 4: Application Notes

Supplemental application notes on the following topics are available by contacting J-KEM.

Application

Note

Subject

AN1

How to heat oil baths with your controller. (Included in Appendix)

AN2

Changing the controller’s thermocouple type.

AN3

Changing the heating outlet into a cooling outlet.

AN4

Using the controller for unattended fractional distillations.

AN5

Using the controller with inductive (motors, valves) loads.

4.1

Theory of How the Controller Works – Simply.

For the purpose of explaining how the controller

works, the example of a solution heated with a heating mantle is used. The principles are the same for all

heater types.

Power

ON

J -KEM

S cie ntific

Instruments for Science

Model 210

120 Vac, 840 watts

120 vac

Power to heater

Thermocouple

Heating mantle

Temperature of process

from the thermocouple

Output

Power Level

1-10 ml

10-100 ml

50-500 ml

300 ml-2 L

> 2 L

Heat

Off

8 0. 0

o

C

*

Figure 2

The controller, the heating mantle and the thermocouple form a closed loop feedback system. If

the process temperature is below the set point, the controller turns the heating mantle on and then

monitors the temperature rise of the solution. If a small rise results (indicating a large volume is being

heated) the controller sets internal parameters appropriate for heating large volumes. If a large rise in

temperature results, the controller responds by loading a set of parameters appropriate for heating small

volumes. For the controller to work ideally, information needs to travel instantaneously around the

feedback loop. That means that any power the controller applies to the heating mantle must reflect itself

in an instantaneous temperature rise of the solution and the thermocouple. Unfortunately, this type of

instantaneous heat transfer from the heating mantle to the solution to the thermocouple just doesn't occur.

The delay time between when power is applied to the heating mantle and when the solution rises in

temperature; and also the converse, when power is removed from the heating mantle and the

solution

temperature stops rising is the source of most controller errors. The reason for this can be seen in a

simple example.