Example power setting explanation – Chemglass CG-1972-65 User Manual

Page 15

15

Heating Liquids. Each power level is associated with a volume range, which acts as a guide when

heating solutions with heating mantles. When solutions are heated with heating mantles set the power

switch to the range that includes the volume of solution being heated [Note: this switch is set to the

volume of solution, not the size of the flask]. For example to heat 250 ml of toluene to 80

o

C in a 1 L

round bottomed flask choose the third power setting (50 - 500 ml) since the solution volume falls within

this range. There are situations when a power level other than that indicated by the front panel should be

used:

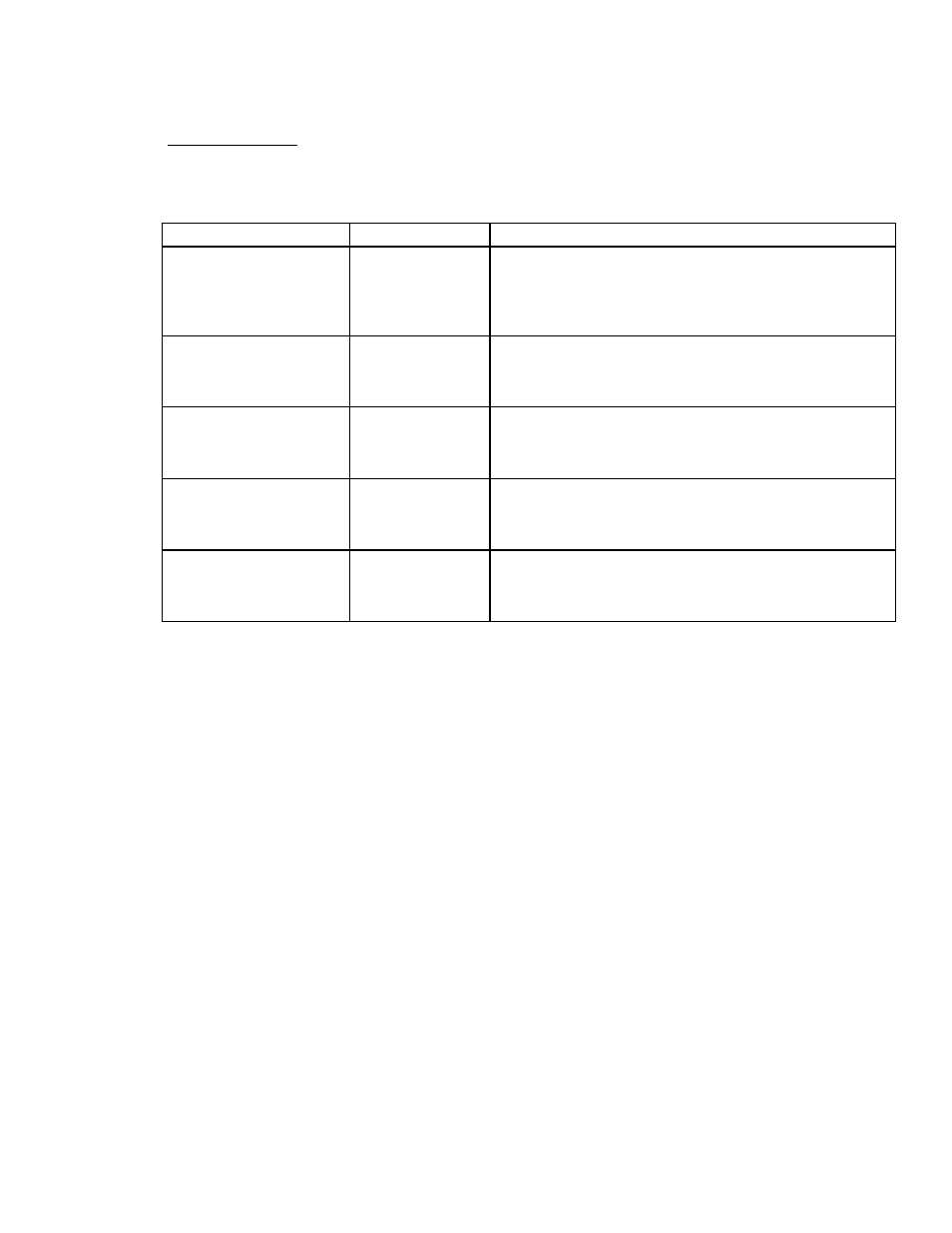

Example

Power Setting

Explanation

80 ml toluene

100 ml flask

100 ml heating mantle

SP = 80

o

C

50 - 500 ml

(25% power)

Organic solvents heated to ≈ 50 - 110

o

C are set to the volume

range on the front panel. When choosing between 2 power

settings (i.e. 80 ml also falls within both the 10 - 100 ml range

and the 50 - 500 ml range) choose the higher setting.

80 ml collidine

100 ml flask

100 ml heating mantle

SP = 170

o

C

300 ml - 2 L

(50% power)

Even though the solvent volume is less than the range of this

power setting, it should be used because high temperatures

require additional power.

80 ml water

100 ml flask

100 ml heating mantle

SP = 80

o

C

300 ml - 2 L

(50% power)

While the setting 50 - 500 ml would work, since the heat

capacity of water is twice that of a typical organic solvent

(1 cal/g/

o

K), a higher power setting can be used to

compensate for the higher heat capacity.

125 ml toluene

1 L flask

1 L heating mantle

SP = 80

o

C

10 - 100 ml

(10% power)

When the heating mantle size is substantially larger (≥ 5X)

than the volume being heated (i.e. the heating mantle has

excess heating capacity for the volume being heated), a lower

power setting gives better control.

150 ml toluene

250 ml flask

250 ml heating mantle

SP = 35

o

C

10 - 100 ml

(10% power)

Even though the solvent volume isn’t included in this power

setting, it should be used because low temperatures are better

regulated with less power.

Avoid switching between the different power levels while the controller is heating. Specifically, do not

initially set the controller on a high power level to rapidly heat the solution, and decrease the power level

to the correct setting as the solution approaches the set point. Changing power levels doesn’t damage the

controller, but it will reduce its heating performance.

Heating Equipment. Two factors need to be considered when heating equipment (ovens, hot plates,

furnaces, HPLC columns, etc.); (1) placement of the temperature sensor (Section 2.4) and, (2) the

appropriate power setting. The best guide to the correct power setting for various pieces of equipment is

the researcher's experience. If your best guess is that the equipment needs 1/3 full power to heat to the set

point, set the power switch on the 300 ml - 2 L setting (i.e., 50% power, it’s usually better to have too

much power rather than too little). If the heater heats too slowly, increase the power (to the >2 L setting),

if it heats too fast or has excessive overshoot, decrease the power (to the 50 - 500 ml setting). If the

amount of power seems to be adequate, but the heater doesn’t heat with stability, the controller probably

needs to be tuned (see Section 2). Section 3.8 shows the type of performance you should expect from the

controller with different pieces of equipment.