Ariens Sno-Thro 920001- ST624E User Manual

Page 12

GB - 12

Scraper Blade

The scraper blade allows the back of the housing to

keep better contact with the surface being cleared. It

also prevents damage to the housing from normal

wear.

IMPORTANT: DO NOT allow Scraper Blade to wear

too far or Auger/Impeller housing will become

damaged.

Runners

The runners control the distance between the scraper

blade and the ground. Adjust runners equally to keep

blade level with the ground. Refer to Pre-Start on

page 12 for recommended settings.

FILLING FUEL TANK

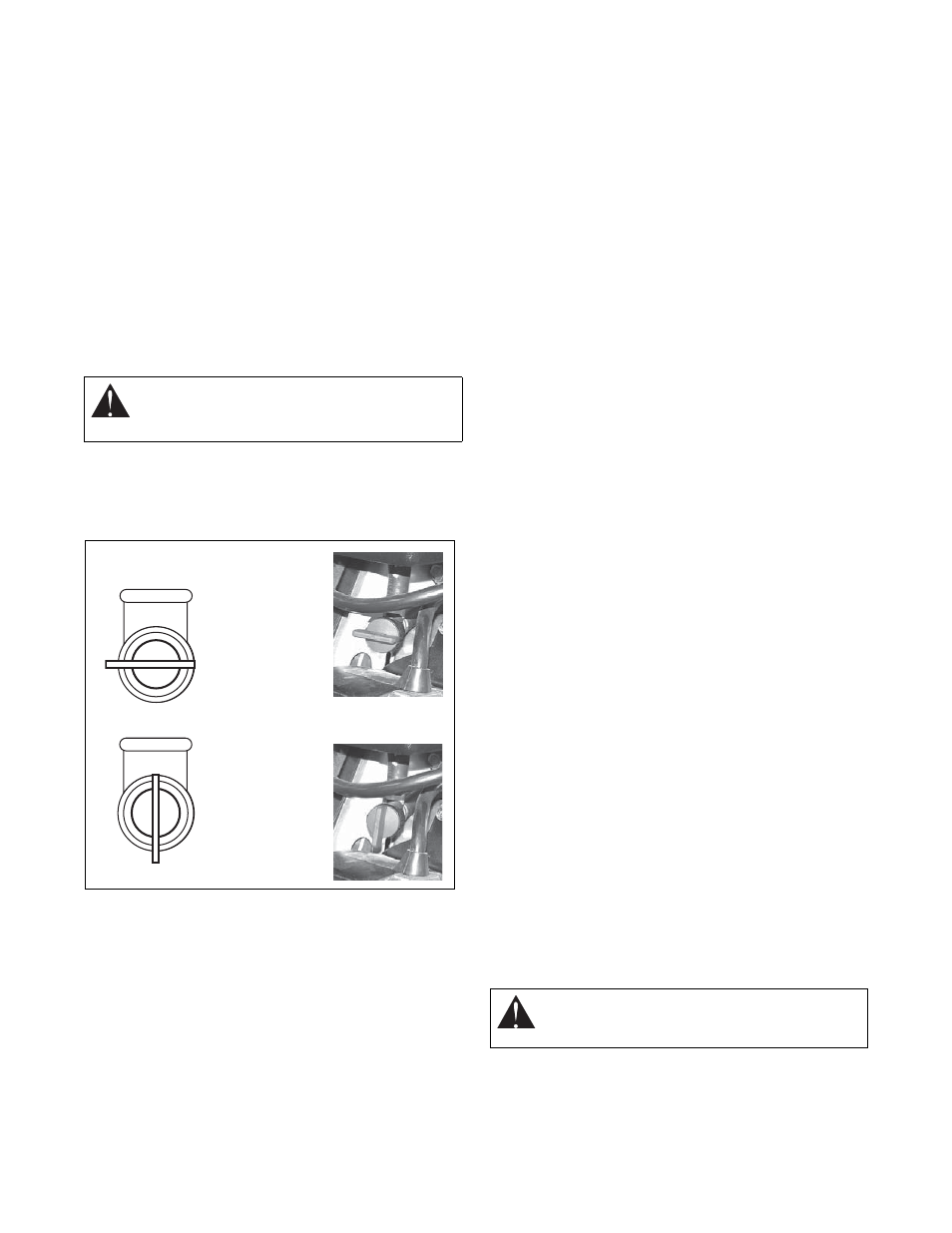

Fuel Shut-Off Valve

IMPORTANT: The fuel shut-off valve MUST be in the

closed position prior to transporting the unit.

The fuel shut-off valve has two positions:

To add fuel to fuel tank:

1. ALWAYS place unit in open or well-ventilated

area.

2. Stop engine and allow to cool.

3. Clean Fuel Cap and surrounding area to prevent

dirt from entering Fuel Tank.

4. Remove Cap.

IMPORTANT: DO NOT use gasohol or gasoline

containing alcohol. See Engine Manual for correct type

and grade of fuel.

5. Fill fuel tank to within 1/2 in. (1.2 cm) below

bottom of filler neck with unleaded gasoline.

NOTE: Tank capacity is 3.5 qt (3.3 L)

6. Replace Fuel Cap and tighten.

7. ALWAYS clean up any spilled fuel.

PRE-START

1. Frozen Impeller

IMPORTANT: Before starting engine, check impeller to

be sure it is not frozen.

To check impeller:

1. With ignition key switch in “Stop” position,

squeeze Attachment Clutch Lever to Engaged

position.

2. Pull Recoil Starter Handle.

3. If Impeller is frozen, (cannot pull Starter Handle)

move unit to a heated area and thaw to prevent

possible damage.

2. Check Function of Clutches

If clutches do not engage or disengage properly, adjust

or repair before operation. See Attachment

Clutch/Brake Adjustment on page 19 and Traction

Drive Clutch Adjustment on page 21

3. Check Dual Handle Interlock

Without the engine running, press down (engage) both

clutch levers. Release attachment clutch lever.

Attachment clutch should remain engaged until traction

clutch lever is released, then both clutches must

disengage.

If clutches do not engage or disengage properly, adjust

or repair before operation (see Attachment

Clutch/Brake Adjustment on page 19 and Traction

Drive Clutch Adjustment on page 21).

4. Check Axle Lock

Use the axle lock pins to lock or unlock the wheels.

Lock both wheels to increase traction; unlock one

wheel to allow for easier turning of the unit.

5. Check Runners

Check and adjust Runners (Runners on page 16).

Allow 1/8 in. (3 mm) between scraper blade and hard,

smooth surface(s). Allow 1-1/4 in. (30 mm) between

scraper blade and uneven or gravel surfaces.

6. Check Engine Fuel & Crankcase Oil

Check and add fuel if required. Check that the engine

crankcase oil is full using dipstick. Refer to Engine

Manual for detailed instructions.

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.

Figure 10

Open Position: Use

this position to run

the unit.

Closed Position:

Use this position

to service,

transport, or store

the unit.

OS7117

WARNING: AVOID INJURY. Read and

understand the entire Safety section before

proceeding.