Rugged Ridge HD Tie Rod & Drag Link Kit, 87-95 Jeep Wrangler (YJ) User Manual

Page 3

H/D Cross –Over steering conversion.

P/N: 18050.82 (XJ-TJ-ZJ) 18050.83 (1987-1995 YJ)

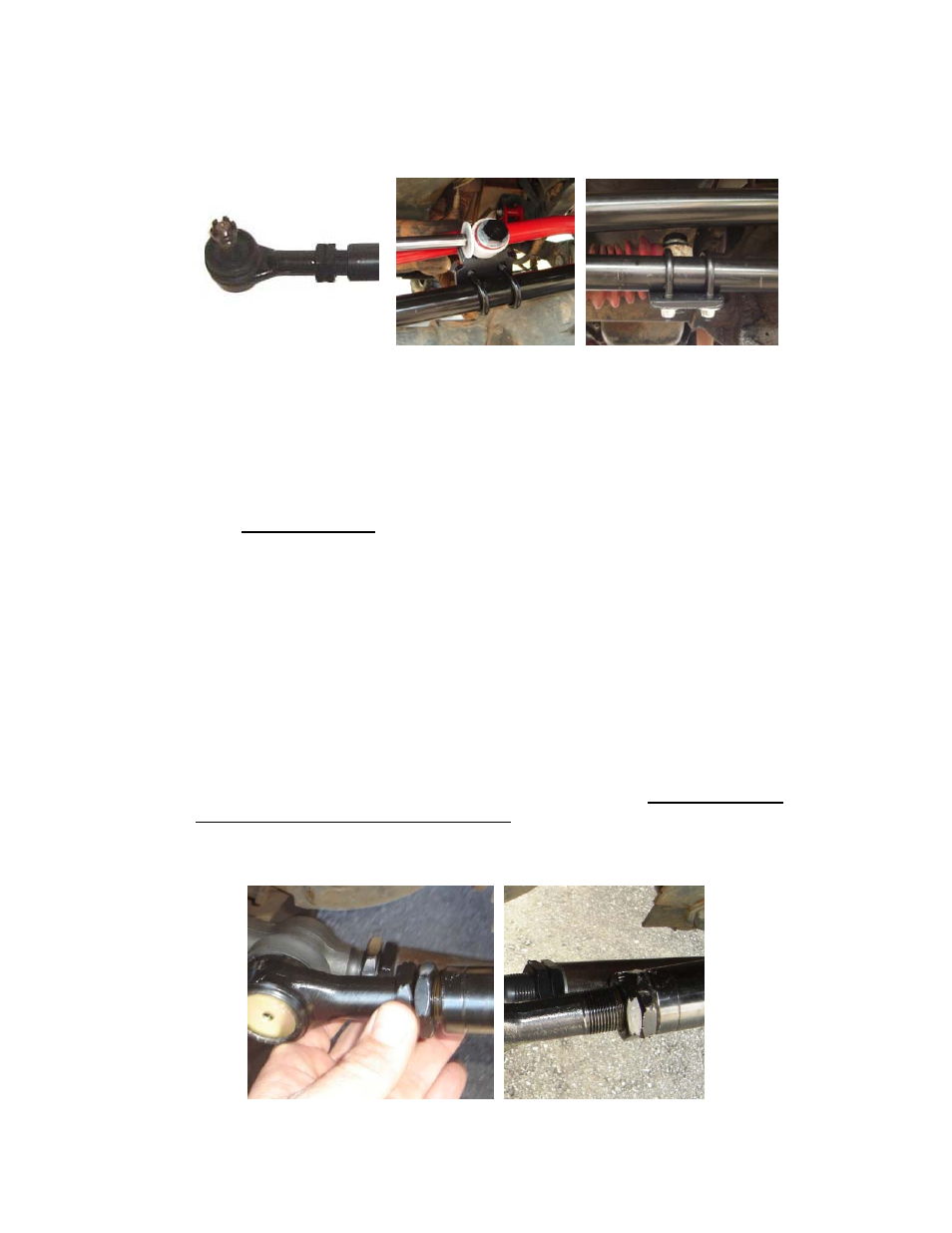

Fig. 3 Fig.4 Fig.5

(4) (ALL) Double check all castle nuts for proper torque setting and insert cotter pins and

grease fittings. Add additional grease if needed. After grease has been inserted remove

nipples and insert supplied plugs. These plugs are to reduce damage when used off-road.

Attach H/D steering stabilizer bracket and position so that no interference with any other

steering component or engine oil pan occurs during full suspension cycle.

The brackets

damper attachment bar is bent to allow for any number of positions. The bracket may be

turned 360degs as the mounting holes are squared to the size of the u-bolts. If your choose to

reusing the old damper it’s tapered bolt will need to be cut off and the new bolt used that is

supplied with the kit. Also the bracket will need to be mounted so that when the Jeep is

sitting with wheels straight there is enough movement in the dampener to allow for full left

and full right turns with no binding or bottoming out. By not moving the damper’s piston

during removal you will be able to determine where the bracket should be located on the

drag-link. Tighten stabilizer nut to 45ft-lbs. The above images are for reference use only

(Fig.4 and 5). The images supplied show one stock height YJ and a 6” lifted TJ. You will

need to determine the proper orientation for your vehicle set-up

(5) (ALL) With steering wheel and steering knuckles aligned tighten the first keeper nut on all

tie-rod ends. NOTE: DO NOT TIGHTEN BOTH NUTS TOGETHER! The first keeper nut

must be tightened before starting the second nut. The assistance of a second person may be

needed to insure that both of the first nuts are properly tightened on each tube (Fig.6). With

the first nuts secured proceed with tightening the second set of keeper nuts. Again the

assistance of a second person may be needed to insure that the second keeper nuts are

properly tightened (Fig.7). Remember that the nuts must be tightened independently of each

other for them to perform properly. If listed steps are not performed the keeper nuts could

back out allowing the tubes to rotate and upsetting your alignment.

It is recommended

that a quality thread lock be used (soft set).

After all nuts have been tightened double

check to make sure no keeper nuts have loosened during the tightening procedure. Check all

nuts at least 3 times.

Fig.6 Fig.7

Page 3