Post-assembly checks, Assembly references, Bolt torque values – Goulds Pumps HT 3196 i-FRAME - IOM User Manual

Page 119: Ost-assembly checks

Post-assembly checks

Perform these checks after you assemble the pump, then continue with pump startup:

• Rotate the shaft by hand in order to make sure that it rotates easily and smoothly and that there is no

rubbing.

• Open the isolation valves and check the pump for leaks.

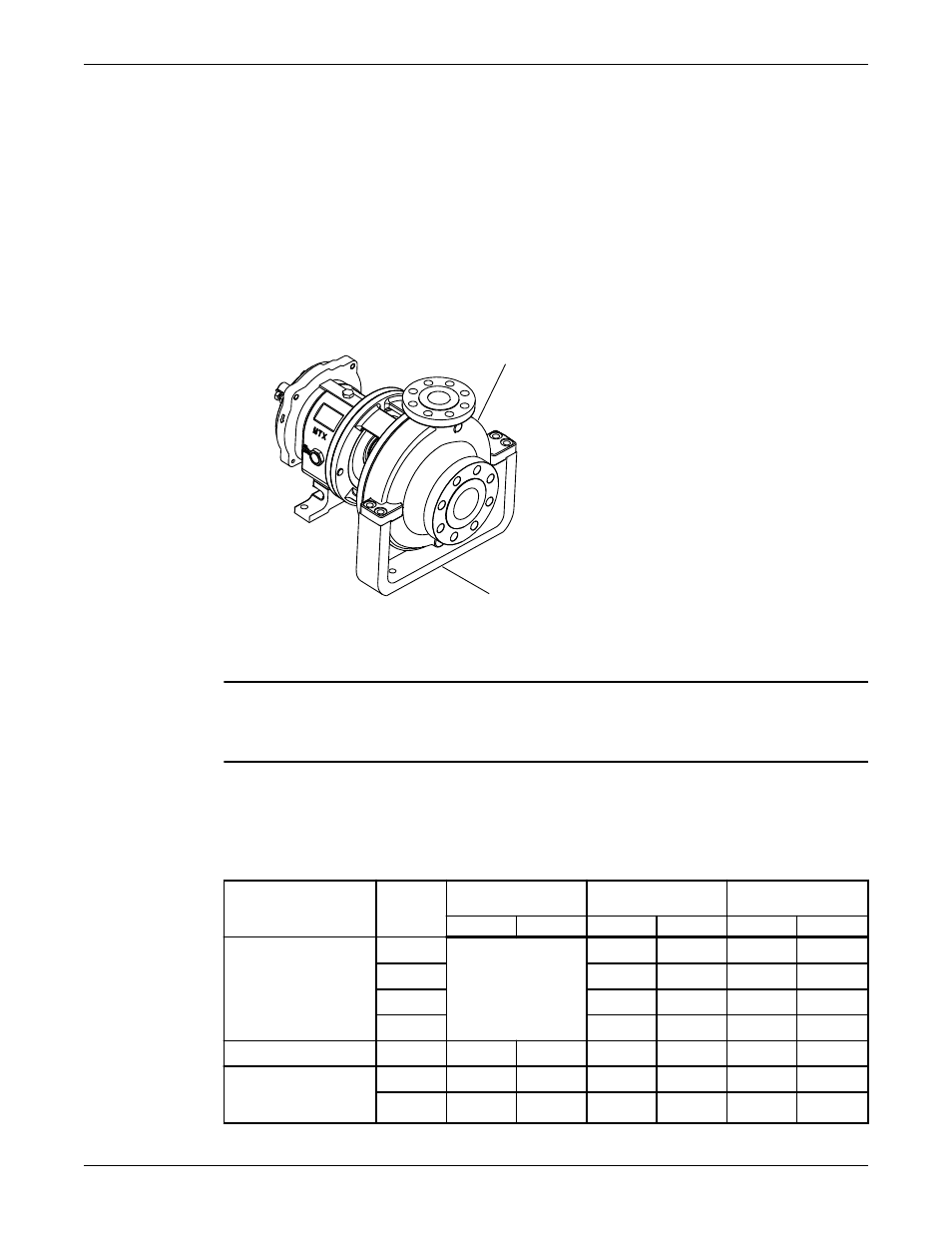

Reinstall the back pull-out assembly for the HT 3196

1. Attach the casing support (239) to the casing (100).

The stamped part number on the casing support is located on the left side when you face the casing

suction.

100

239

2. Reinstall the coupling guard.

Refer to the Install the coupling guard section for more information.

NOTICE:

Risk of damage to the mechanical seal or shaft sleeve on units supplied with cartridge mechanical seals.

Prior to startup, make sure to tighten the set screws in the seal locking ring and remove the centering clips.

Assembly references

Bolt torque values

This table provides the bolt torque values.

Table 17: Bolt torque, lb-ft (Nm)

Location

Frame

3196, CV 3196, LF

3196, 3796

NM 3196

3198

Lube

Dry

Lube

Dry

Lube

Dry

Casing bolts (370) or

casing nuts (425)

6-in. STi

Refer to the

maximum torque

values in lb-ft (Nm)

for casing bolts table.

27 (36)

40 (53)

N/A

N/A

8-in. STi

20 (27)

30 (40)

35 (47)

53 (71)

MTi, LTi

27 (36)

40 (53)

35 (47)

53 (71)

XLT-i, i17

N/A

N/A

N/A

N/A

Frame-to-adapter bolts All

20 (27)

30 (40)

20 (27)

30 (40)

20 (27)

30 (40)

Bearing-clamp ring

bolts (236A) - duplex

bearing only

STi, MTi 10* (1.1)

17* (1.9)

10* (1.1)

17* (1.9)

10* (1.1)

17* (1.9)

LTi

55* (6.2)

83* (9.4)

55* (6.2)

83* (9.4)

55* (6.2)

83* (9.4)

Maintenance

Model HT 3196 i-FRAME Installation, Operation, and Maintenance Manual

117