Grout the baseplate – Goulds Pumps 3355 - IOM User Manual

Page 21

Installation

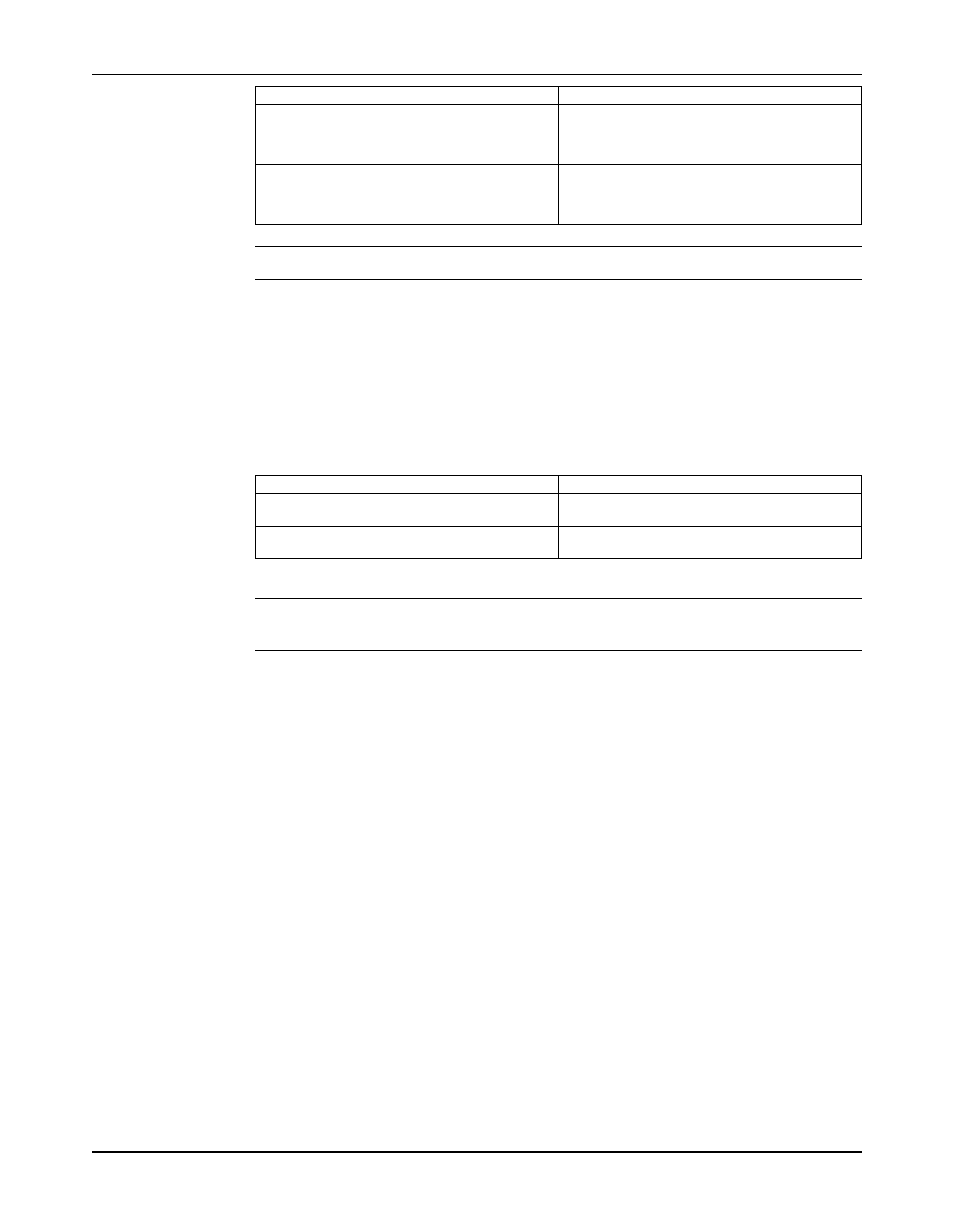

When the reading value is...

Then...

Negative

The pump coupling half (X) is lower than the

driver coupling half (Y). Remove shims of a

thickness equal to half of the indicator reading

value under each driver foot.

Positive

The pump coupling half (X) is higher than the

driver coupling half (Y). Add shims of a thickness

equal to half of the indicator reading value to each

driver foot.

NOTICE:

4. Repeat the previous steps until the permitted reading value is achieved.

Perform parallel alignment for a horizontal correction

A unit is in parallel alignment when the parallel indicator (P) does not vary by more than as

measured at four points 90° apart at the operating temperature.

1. Set the parallel alignment indicator (P) to zero on the left side of the driver coupling half (Y),

90° from the top-center position (9 o’clock).

2. Rotate the indicator through the top-center position to the right side, 180° from the start

position (3 o’clock).

3. Record the indicator reading.

When the reading value is...

Then...

Negative

The driver coupling half (Y) is to the left of the

pump coupling half (X).

Positive

The driver coupling half (Y) is to the right of the

pump coupling half (X).

4. Slide the driver carefully in the appropriate direction.

NOTICE:Make sure to slide the driver evenly. Failure to do so can negatively affect

horizontal angular correction.

5. Repeat the previous steps until the permitted reading value is achieved.

Perform complete alignment for a vertical correction

1. Set the angular and parallel dial indicators to zero at the top-center position (12 o’clock) of

the driver coupling half (Y).

2. Rotate the indicators to the bottom-center position (6 o’clock).

3. Record the indicator readings.

4. Make corrections according to the separate instructions for angular and parallel alignment

until you obtain the permitted reading values.

Perform complete alignment for a horizontal correction

1. Set the angular and parallel dial indicators to zero at the left side of the driver coupling half

(Y), 90° from the top-center position (9 o’clock).

2. Rotate the indicators through the top-center position to the right side, 180° from the start

position (3 o’clock).

3. Record the indicator readings.

4. Make corrections according to the separate instructions for angular and parallel alignment

until you obtain the permitted reading values.

Grout the baseplate

Required equipment:

• Cleaners: Do not use an oil-based cleaner because the grout will not bond to it. See the

instructions provided by the grout manufacturer.

Model 3355 Installation, Operation, and Maintenance Manual

19