Dow THERMAX™ Wall System User Manual

Page 3

I N S T A L L A T I O N

I N F O R M A T I O N

.

C O M M E R C I A L

while applying the foam.

• Spray equipment must be capable

of delivering the proper ratio

(1:1 by volume) of polymeric

isocyanate and polyol blend at

the recommended temperatures

and spray pressures (Table 1).

To minimize the potential for

off-ratio product, the use of a

common drive on the positive

displacement pumps of the

proportioner is recommended.

• Follow the spray equipment

manufacturer’s guidelines for

all spray operations. Spray units

and guns come in a variety of

capacities and styles and will

require adjustments to achieve

the desired spray pattern.

AMBIENT AND SUBSTRATE

CONDITIONS

Substrate must be at least 5 degrees

above dew point, with best process-

ing results when the relative humidity

is below 80 percent (<18 percent

substrate moisture content if wood or

concrete is the substrate). To minimize

potential for moisture interference with

adhesion of STYROFOAM

™

Brand

SPF (CM Series) to the substrate, spray

only when the relative humidity is

below 70 percent (<12 percent substrate

moisture content if wood or concrete

is the substrate).

SURFACE PREPARATION

• The steel stud and THERMAX

™

(ci)

Exterior Insulation substrates

must be free of moisture (dew or

frost), grease, oil, solvents and

other materials that would

adversely affect the adhesion of

the polyurethane foam. Poor

adhesion will result in stud line

cracking of the SPF.

• THERMAX

™

(ci) Exterior Insulation

and the steel studs do not need

to be primed unless the studs are

weathered or previously painted.

If priming is desired, clean the

surface per primer manufacturer’s

recommendations and use a

primer known to be compatible

with spray polyurethane foam.

• Most untreated and unpainted wood

does not need to be primed.

• Substrate temperatures should

not exceed 120°F for STYROFOAM

™

Brand SPF CM 2060, 100°F for

STYROFOAM

™

Brand SPF CM

2045 and 60°F for STYROFOAM

™

Brand SPF CM 2030. Excessive

temperatures will lead to fast gel

times and low yield.

APPLICATION GUIDELINES

Due to the exothermic reaction of

the isocyanate and polyol blend,

STYROFOAM

™

Brand SPF (CM

Series) should be applied in layers

1/2" to 1-1/2" thick. Application of

one layer of 1-1/2" thick is

recommended for optimum yield

and performance. Allow the foam to

cool completely before applying

successive layers. If spraying to full

cavity depth, maximum thickness

per layer is 2". Excessive

thicknesses can lead to void

formation and even internal char,

reducing the thermal and

mechanical quality of the foam.

To minimize void formation where

the sheathing is attached to the steel

studs, apply foam in the cavity where

the steel stud and sheathing meet

(picture framing technique) prior to

filling the cavity. Allow the foam to

fully cool and then spray to the desired

thickness by filling in the area between

the previously applied foam using a

side-to-side motion within each cavity.

STYROFOAM

™

Brand SPF (CM

Series) should be covered as soon as

feasible during the construction process.

There is no need to wait for any off-

gassing of the foam as this happens

immediately during application.

OVERSPRAY NOTES

Overspray can lead to several prob-

lems on the job site if not controlled

properly. Overspray will coat all

surfaces in a room and if windows

and doorways are left open, the

overspray can reach other rooms

and vehicles outside the building.

Cover objects near the application

area that might be coated with over-

spray. Excessive overspray can

accumulate on areas that are

intended for STYROFOAM™ brand

Spray Polyurethane Foam Insulation

(CM Series) application. Overspray

can be brittle and may affect the

adhesion of the STYROFOAM™

brand Spray Polyurethane Foam

Insulation (CM Series) on

oversprayed substrates. When

STYROFOAM™ brand Spray

Polyurethane Foam Insulation (CM

Series) is applied to an area coated

with excessive over-

spray, delamination can result.

To minimize overspray, do not

apply STYROFOAM

™

Brand SPF

(CM Series) if there is air movement

in the room due to wind or fans.

Point the gun perpendicular to the

surface being sprayed and as close

as possible without causing

spattering or a popcorn pattern.

COLD WEATHER APPLICATION

Applying STYROFOAM

™

Brand SPF

CM 2030 to the interior stud cavity

side of THERMAX

™

(ci) Exterior

Insulation when outside temperatures

are below 30°F can be accomplished

with the following precautions:

• Heat the area to be sprayed to

≥30°F for a minimum of 2 hours

prior to spraying for both the

ambient air and substrate

temperature. This is best done

with window and doorway areas

closed to improve even heating.

Dry off any areas that might have

formed moisture on the surface

before spraying.

• Check the substrates (sheathing

and studs) and ensure no

moisture condensation is present.

After applying the spray foam,

maintain the temperature at ≥30°F

for 48 hours.

SPF TROUBLESHOOTING TIPS (SEE

TABLE 2)

Reduced yield and excessive shrink-

age leading to stud line cracking are

the more common issues that SPF

applicators face. The best rule of

thumb is to stop applying foam to

the walls if the foam looks different.

“Different” would include color

changes, color swirls, faster/slower

than normal cream, non-circular or

smaller/larger than usual spray

pattern, foam reversion and poor

wetting of the substrate.

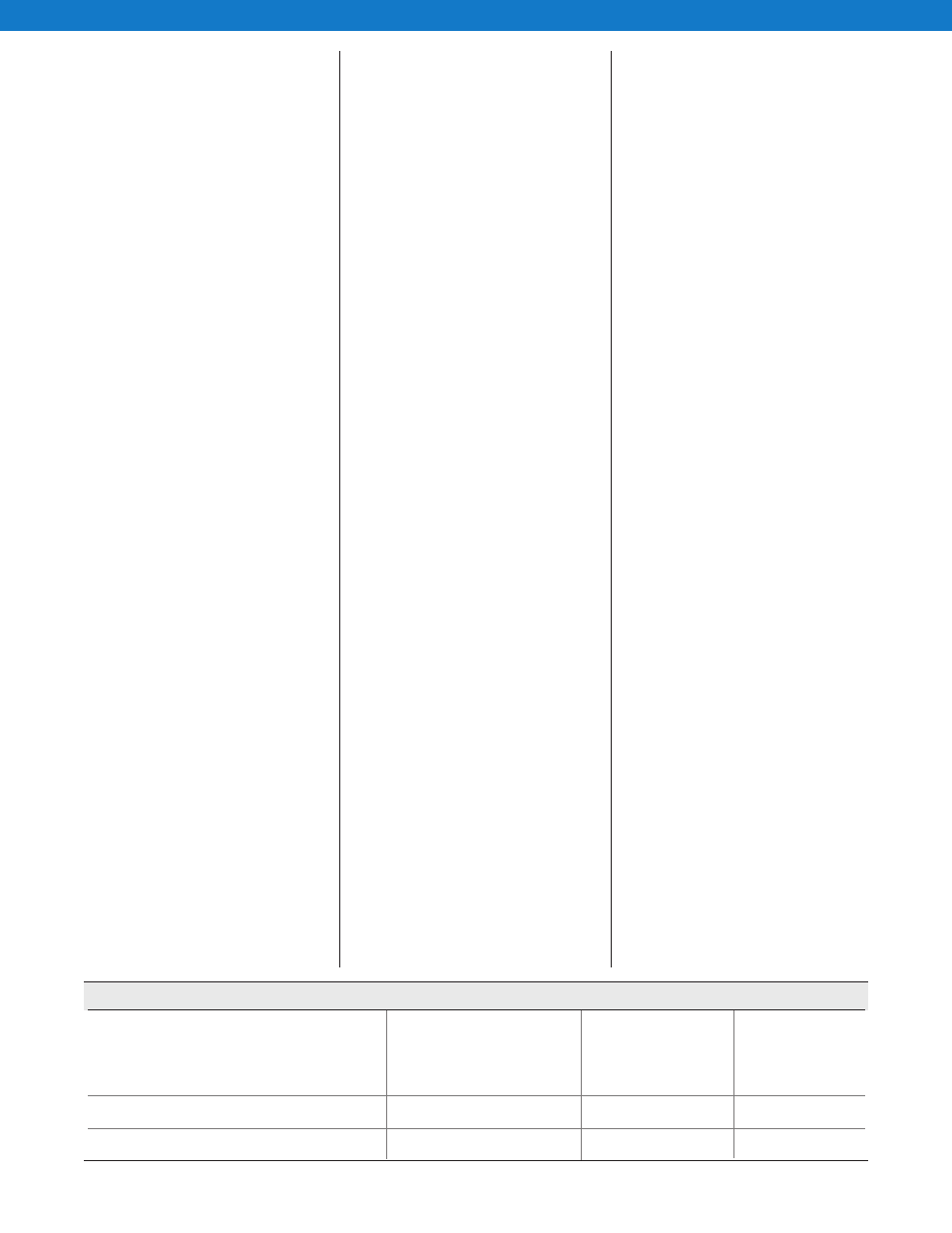

Recommended Equipment

Relative Humidity %: <80

Substrate Temp (°F)

Ambient Temp (°F)

• Graco/Gusmer A-20, E20/30, H25/40 proportioner

CM 2030: 30-60

CM 2030: 30-70

or equivalent

CM 2045: 45-100

CM 2045: 45-95

• Graco/Gusmer Fusion AP, MP, CS, Probler P2 gun

CM 2060: 60-120

CM 2060: 60-100

or equivalent

• #0.01-0.03 mix chamber or equivalent

Difference Between Ambient and

Primary Heater Temp (°F): 115-130

(1)

Hose Temp (°F): 115-130

(1)

Dew Point Temperatures (°F): >5

Dynamic Pressure “A” (psi):

Dynamic Pressure “B” (psi):

SPF max.: 1.5" thick

Mixing Ratio A/B: 1:1

600-1200 (800

(2)

)

600-1200 (800

(2)

)

TABLE 1: RECOMMENDED PROCESSING PARAMETERS – CM 2030, CM 2045 AND CM 2060

(1) To minimize potential for stud line cracking, STYROFOAM™ Brand SPF CM 2030 should be applied at the higher end of temperature and pressure ranges.

(2) Recommended initial pressure

®™Trademark of The Dow Chemical Company (“Dow”) or an affiliated company of Dow