Beijer Electronics AN-BEI-P2-050 User Manual

Page 2

APPLICATION NOTE AN-BEI-P2-050

Date: 15/02/12

AN-BEI-P2-050 Open Loop Permanent Magnet Motor Control

2

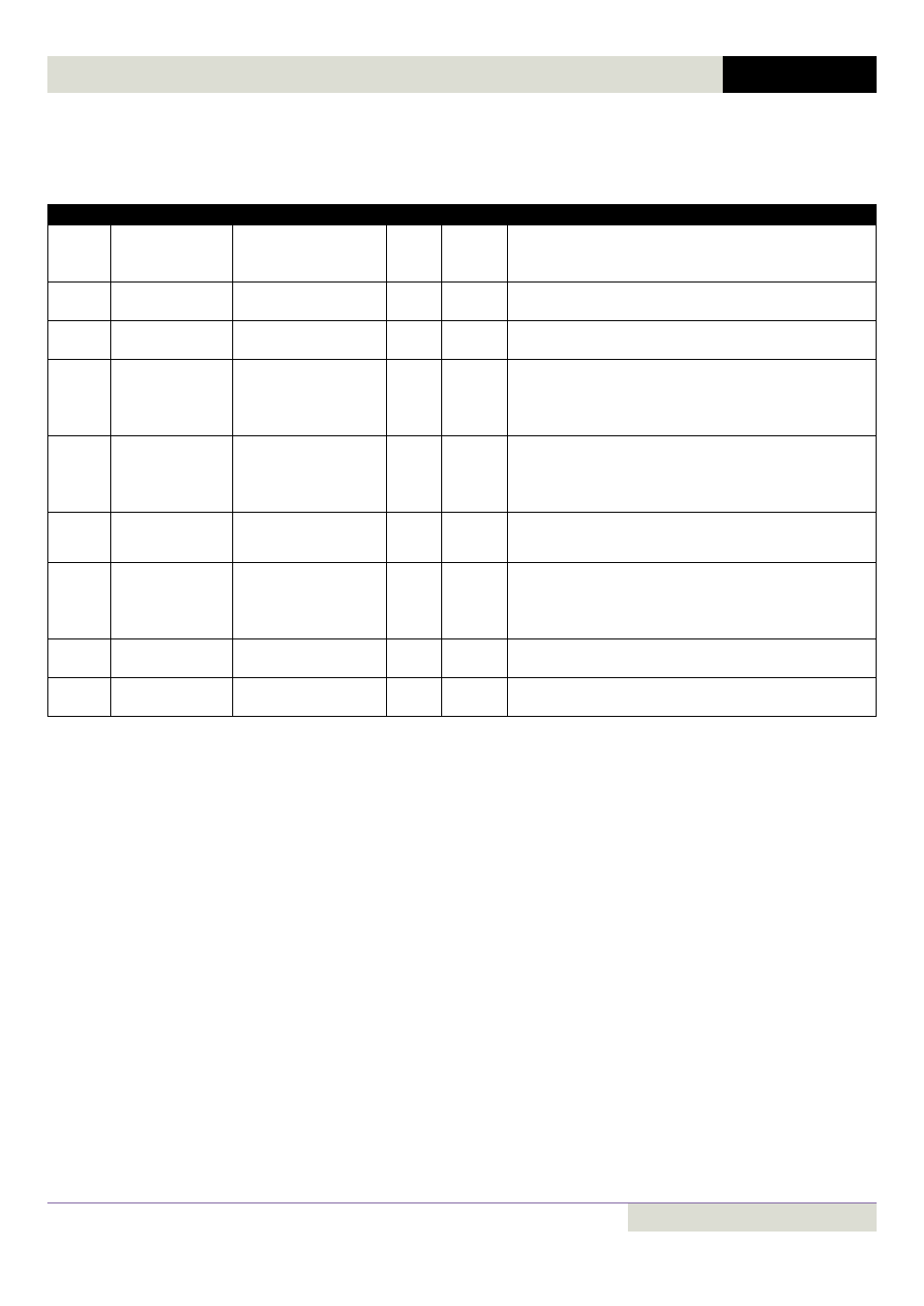

Firmware Overview – Additional Parameters and Settings:

Additional Parameter information to that provided in the standard Beijer Frequency Inverter P2 manual is as

follows:-

Par.

Description

Range

Units

Default

Explanation

P1-14

Extended menu

access

Code 0 to 30000

---

0

Set to ‘201’ for access to PM motor control parameters.

PM motor selection setting (in P4-01) and menu 7 are

not visible when other value (than 201) is set.

P4-01

Control Mode

0, 1, 2: See Std Guide

3: PM Motor Control

---

2

Selects the motor control method.

Set to ‘3’ for Sensor-less PM motor control

P7-01

Stator

Resistance

0.000 – 50.000

ohm

2.8

Motor Stator Resistance (phase –phase).

Measure with ‘auto-tune’ or enter manually.

P7-03

Lsd Phase

Inductance

0.0000 – 1.0000

Henry

0.13

Inductance Per Phase.

‘d’ component of armature winding inductance from

the d-q linear model.

Measure with ‘auto-tune’ or enter manually.

P7-06

Lsq Phase

Inductance

0.0000 – 1.0000

Henry

0.13

Inductance Per Phase.

‘q’ component of armature winding inductance from

the d-q linear model.

Measure with ‘auto-tune’ or enter manually.

P7-10

Inertia Ratio

0 - 100

%

10

System Load Inertia to Motor Inertia Ratio. Entered into

P7-10 as:

P7-10 = (J

Tot

/ J

Mot

) . 10

P7-12

Current

magnetising

time

0 - 2000

mS

45

Motor magnetising time at start.

Time following drive enable to establish magnetising

flux in motor windings in order to accurately phase

motor shaft.

P7-14

Boost Current

Level

0 - 100

%

0

Boost current applied at start-up, as % of motor rated

current (P1-08)

P7-15

Boost

Frequency

0 – 50

%

0

Frequency range for applied boost current (P7-14) as %

of motor rated speed (P1-10)