Nor-Lake Lighted Chambers User Manual

Page 6

- 6 -

ELECTRICAL

For electrical requirements see data information and wiring unit diagram located in parts

bag, inside of the cabinet.

Check the proposed external power outlet/supply to be used to ensure that the voltage,

phase and current carrying capacity of the circuit from the electrical panel correspond to the

requirements of the cabinet. NEVER use an extension cord to wire any unit. Refer to the

serial tag (nameplate data) for all pertinent electrical information.

Observe all Warning Labels. Disconnect power supply(s) to eliminate injury from

electrical shock or moving parts when servicing equipment.

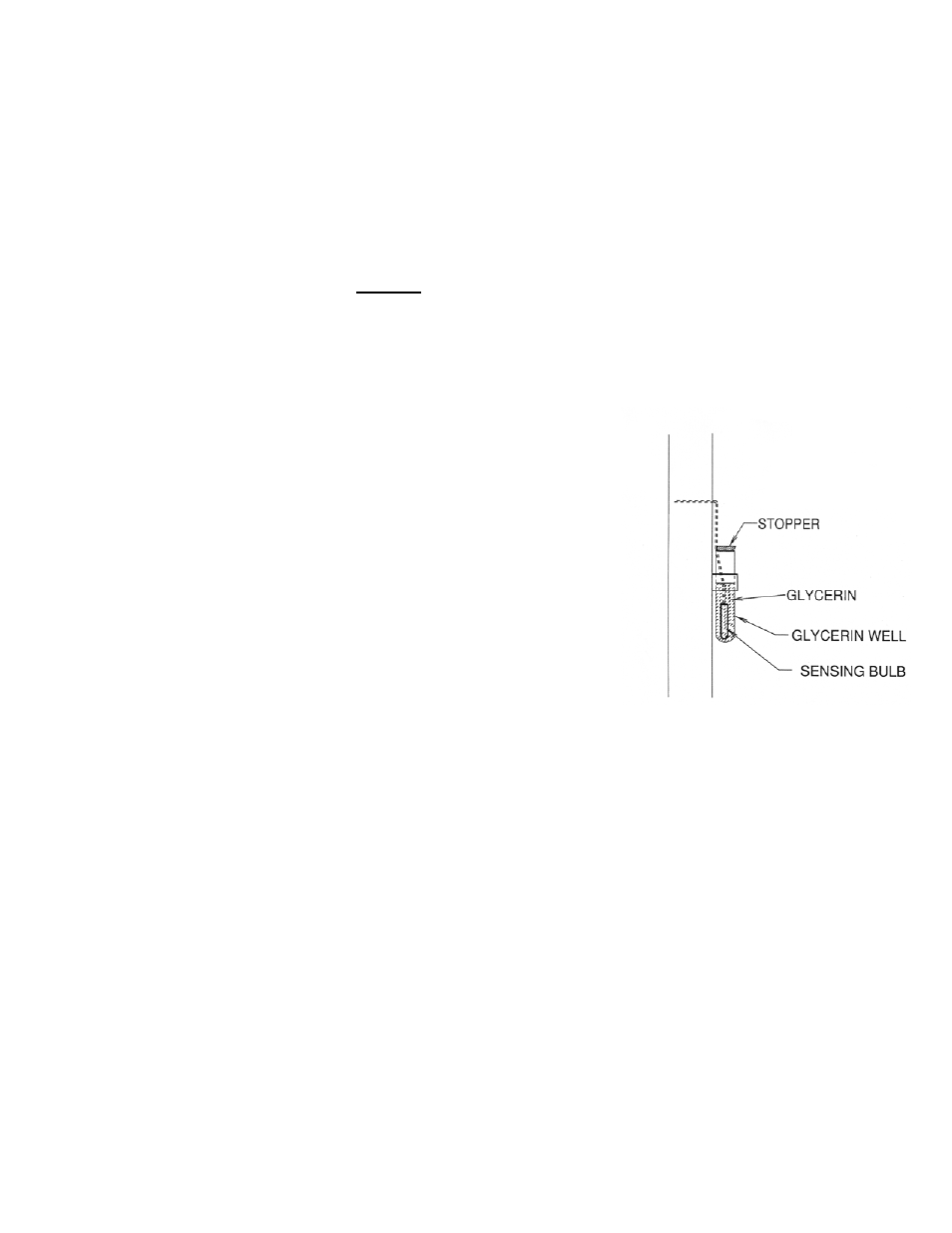

GLYCERIN WELL ASSEMBLY

Important:

For accurate product temperature reading, the

product-sensing bulb must be immersed in glycerin solution

contained in the provided well.

One glycerin well is furnished with each model. The

purpose of the glycerin is to simulate the product stored in

the Lighted Chamber. The glycerin temperature reflects the

product's temperature during normal operation.

Figure

1

After the unit is put into operation. Check to make sure that

the temperature indicating or alarm sensing bulb is

positioned inside the glycerin well. As far as possible

without touching the well itself.

OPERATION

The Lighted Chambers are designed for an operating range of 4°C to 44°C Temperature

only, 5°C to 44°C Temperature with Humidity and is intended for indoor use only.

These units employ a programmable controller to control the temperature, defrost and

humidity settings. The controller, which is located on the facade of the unit, is factory set.

Please see the separate instructions, part number 113635, on the operation of the

controller used in the Stability Chambers.

The cabinets use an evaporator coil, located on top of the cabinet as the heat-removing

source. Through the refrigeration process, heat is captured in the evaporator, transferred to

the condensing unit on top of the cabinet, and expelled to the surrounding outside air. It is

extremely important to allow a four-inch clearance on the top, rear, and sides of the unit for

the refrigeration process to function properly.

The cabinets utilize electrically operated heaters to warm the cabinets in the heating mode.

The heating elements are located in the interior cowl. The programmable control is factory

set with a cutout temperature to prevent the cabinet from exceeding its design limits.