Anco Eaglin A-E Cooker 600-12 User Manual

Page 2

120 North Chimney Rock Road • Greensboro, North Carolina 27409

336-855-7800 • FAX 855-7831 • e mail: [email protected]

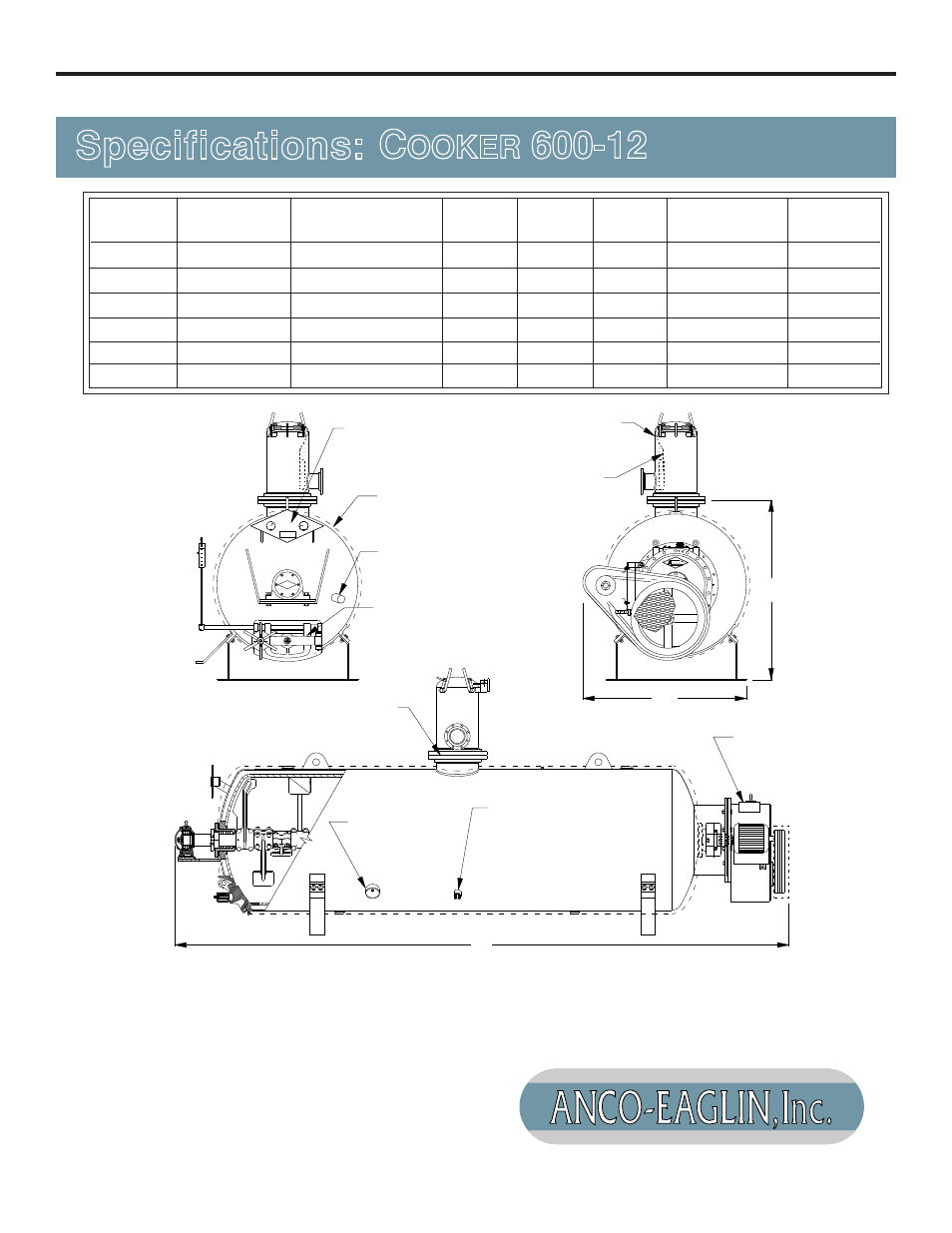

Cooker

Size

5’ x 8”

5’ x 10’

5’ x 12’

5’ x 13’4”

5’ x 16’

5’ x 18’

Gross Volume

Cu. Ft./Liters

107/3,030

143/4,050

180/ 5,100

204 / 5,780

252/ 7,130

288/8,150

“H”

FT./M.

6.3 /1.9

6.3 /1.9

6.3 /1.9

6.3 /1.9

6.3 /1.9

6.3 /1.9

“W”

FT./M.

5.7/1.7

5.7/1.7

5.7/1.7

5.7/1.7

5.7/1.7

5.7/1.7

“L”

FT./M.

13.9/4.2

15.9/4.8

17.9/5.5

19.2/5.9

21.9/6.7

23.9/ 7.3

Batch Capacity

(Raw Material @50lb./cu.ft.) lb/kg

4,010/1,820

5,360/2,432

6,750/3,062

7,650/3,470

9,450/4,287

10,800/4,900

Approx. Shipping

Weight lbs./kgs.

17,800 / 8,000

19,700 / 9,000

21,600 / 9,900

22,800/10,400

25,300/11,500

27,200/12,400

Motor HP

Required Offal/

Feathers

20/30

25/40

30/50

30/50

40/60

50/75

GENERAL CONSTRUCTION DATA:

Both inner and outer shells are constructed

of pressure vessel quality type ASTM 516-70

alloy steel or (optional) stainless steel

inner shell.

RATE CAPACITY:

Is dependent on process conditions,

product type and quality of steam.

STEAM REQUIREMENTS:

1.3 to 1.4 pounds of steam per pound of water

evaporated as per vessel with (optional) high

quality factory standard insulation jacket.

W

18" OR 24"

DOME ASSY.

(OPTIONAL)

FEELER POINT

FOR ANCO NO. 1205

RENDERING INDICATOR

(OPTIONAL)

SAMPLING

VALVE

(OPTIONAL)

DISCHARGE DOOR ASSEMBLY

OR (OPTIONAL) AUTOMATIC

DOOR CLOSURE SYSTEM FOR

0 PSIG DRYING APPLICATION

H

VAPOR

SCREEN

POW-R-PAK

NO.12

GEARBOX

L

INSULATION JACKET

1-1/2" OR 2" THICK

(OPTIONAL)

CUSTOMER MAY SPECIFY INLET

POSITIONING. ADDITIONAL MATERIAL

INLET CONNECTIONS ARE OPTIONAL

TEMPERATURE

SENSOR

(OPTIONAL)

ANCO

INSTRUMENT PANEL

WITH TWO GAUGES:

JACKET PRESSURE &

INTERNAL PRESSURE