The 1212 hydrolyzer, Anco-eaglin, inc, The history of the hydrolyzer – Anco Eaglin Continuous Hydrolyzer 1212 User Manual

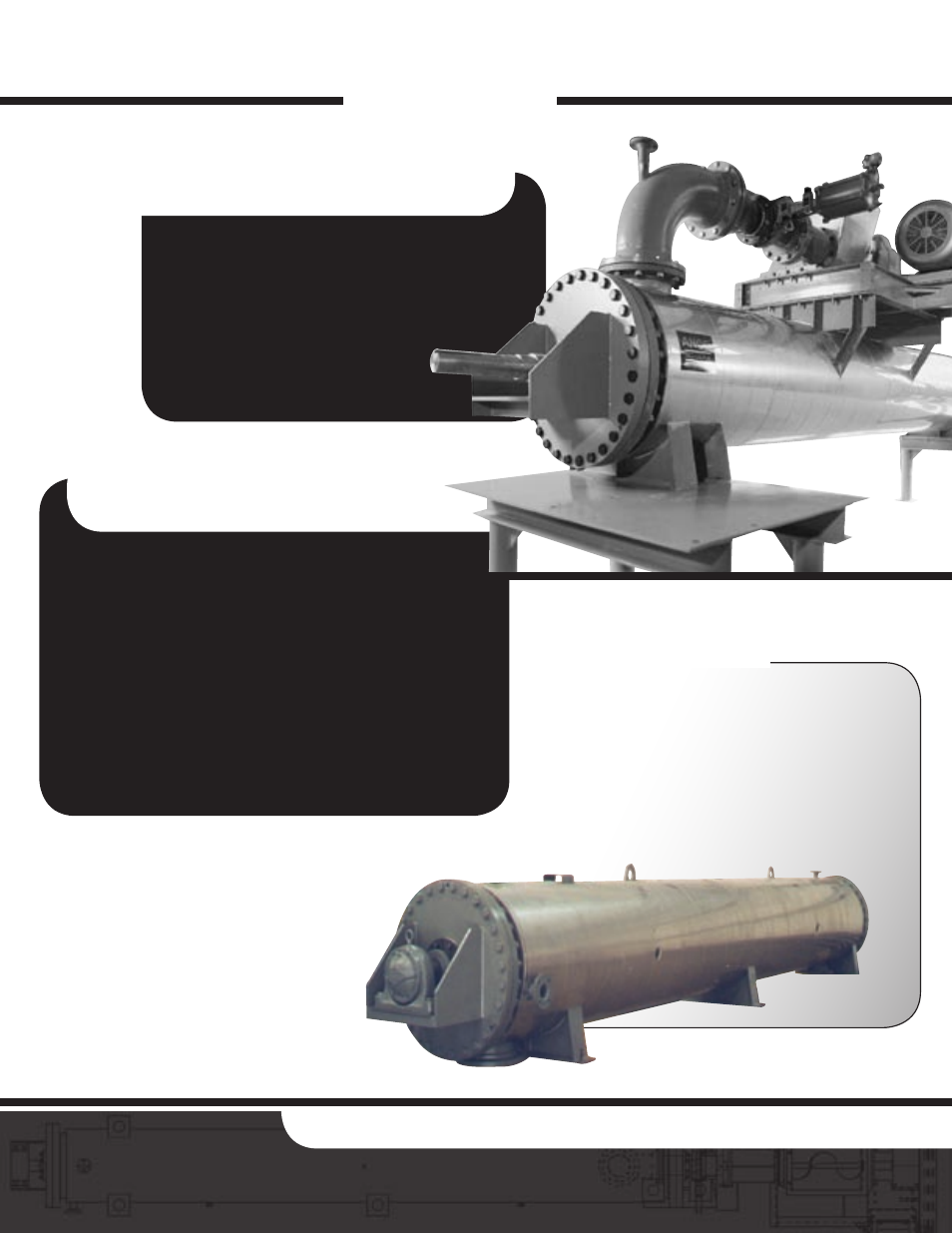

Page 2: Pressure vessel, Anco 1212 continuous hydrolyzer

ANCO-EAGLIN, Inc.

120 North Chimney Rock Road • Greensboro, North Carolina 27409

336-855-7800 • FAX 336-855-7831 • E-mail: [email protected] • WWW.ANCOEAGLIN.COM

The

1212

Hydrolyzer

ANCO originated continuous hydrolyzer technology and was

the fi rst company to patent the process. The fi rst continuous

hydrolyzer was installed at Southern Rendering in Little Rock,

Arkansas, in the mid-1960s. Today, ANCO Continuous

Hydrolyzers are a preferred choice of rendering customers

throughout the world. With slight modifi cations,

the ANCO Continuous Hydrolyzer can also

be used for waste sterilization and corn-stalk processing.

The History of the Hydrolyzer

ANCO-EAGLIN has continued to innovate its 1212 Hydrolyzer, adding

components designed to offer a variety of new and improved features:

•

Processes chicken and turkey feathers and hog and beef hair

•

Consumes one pound of steam for every three pounds of raw material

•

Discharges feather moisture content in the 59±% range

•

Raises product quality and protein digestibility due to the rapid heating

and short resonance time inside the vessel

•

Available in several production sizes ranging from 3,000 to more than

30,000 pounds per hour

Pressure Vessel

•

Consists of a heavy wall inner shell constructed from

stainless steel

•

Produces higher ASME pressure ratings (125 psig. inner

shell; 150 psig. jacket pressure with EC and CRN certifi cations)

•

Features an energy-effi cient insulation jacket consisting of

high R-value wrapping covered by a stainless-steel sheet

•

Generates substantial savings in steam use with minimal

heat loss

ANCO 1212

Continuous Hydrolyzer