Vertical contact toaster, Troubleshooting (continued) – A.J. Antunes & Co VCT-1000 9210719 User Manual

Page 13

13

P/N 1010930 Rev. C 09/13

VERTICAL CONTACT TOASTER

TROUBLESHOOTING (continued)

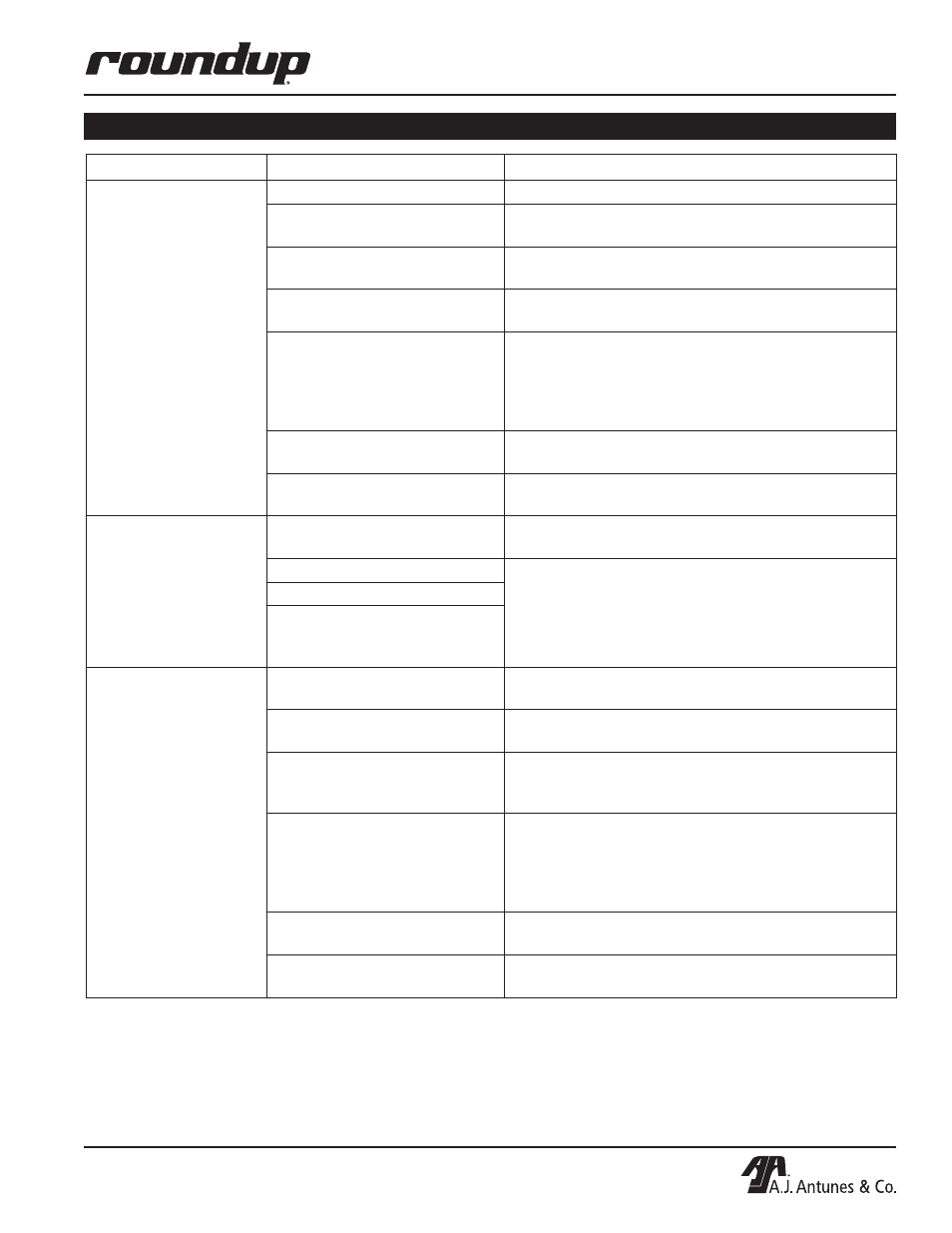

Problem

Possible Cause

Corrective Action

Product is over toasted

or Platen heat is too

high or drop time is too

slow.

Temperature set too high.

Set Temperature Control to a lower setting.

Bun Thickness Compression

Knobs set improperly.

Measure bun thickness and set Bun Thickness

Compression Knobs accordingly.

Buns sticking on Release Sheet. Clean or replace Release Sheet as described in the

Maintenance section of this manual.

Conveyor Cover Assembly not

installed properly.

Re-install Conveyor Cover Assembly.

Loose sprocket setscrews.

Check drive chain for kinks, broken or bent links,

or other damage. Check motor sprocket and drive

sprockets; tighten setscrew on flat of shaft if required.

Check for damaged/worn sprocket and replace as

required.

Conveyor Belt Chain too loose.

Adjust Conveyor Belt Chain length as described in the

Maintenance section of this manual.

Spring Tensioner Assembly is

damaged or missing.

Replace Spring Tensioner Assembly if damaged or

missing.

Product is under toast-

ed or Platen heat is too

low or drop time is too

fast.

Bun Thickness Compression

Knobs set improperly.

Measure bun thickness and set Bun Thickness

Compression Knobs correctly.

Wiring problem.

Contact your maintenance person or Authorized

Service Agency for service.

Inoperable Thermostat.

Conveyor Drive Motor inoper-

able or incorrect conveyor motor

or sprocket installed.

Product is getting

stuck or Conveyor Belt

Chains stop when

product is toasting.

Bun Thickness Compression

Knobs Set improperly.

Measure bun thickness and set Bun Thickness

Compression Knobs accordingly.

Release Sheet not cleaned

properly or is missing.

Clean or replace Release Sheet as described in the

Maintenance section of this manual.

Conveyor Drive motor inopera-

tive or incorrect voltage motor

installed in toaster.

Contact your maintenance person or Authorized

Service Agency for service.

Conveyor Drive Chain loose,

worn, or broken. Loose motor

drive sprocket.

Check drive chain for kinks, broken or bent links,

or other damage. Check motor sprocket and drive

sprockets, tighten setscrew on flat of shaft if required.

Check for damaged/worn sprockets and replace as

required.

Conveyor Belt Chain too loose.

Adjust Conveyor Belt Chain length as described in the

Maintenance section of this manual.

Spring Tensioner Assembly is

damaged or missing.

Replace Spring Tensioner Assembly if damaged or

missing.