Figure 40 – Amana VR8205 User Manual

Page 25

25

O

F

F

ON

M

P

C

1

3

2

WR

INLET

OUTLET

Main Regulator

Adjust

Inlet Pressure Tap

(Side of Valve)

Outlet Pressure Tap

(Side of Valve)

Main

Solenoid

Redundant

Solenoid

ON/Off

Switch

Figure 39

White Rodgers Model 36E22

CHECK GAS INPUT AND PRESSURES

Gas supply pressure and manifold pressure with the burn-

ers operating must be as specified on the rating plate.

CHECKING GAS PRESSURE

Gas inlet pressure should be checked and adjusted in

accordance to the type of fuel being consumed.

With Power and Gas Off:

1.

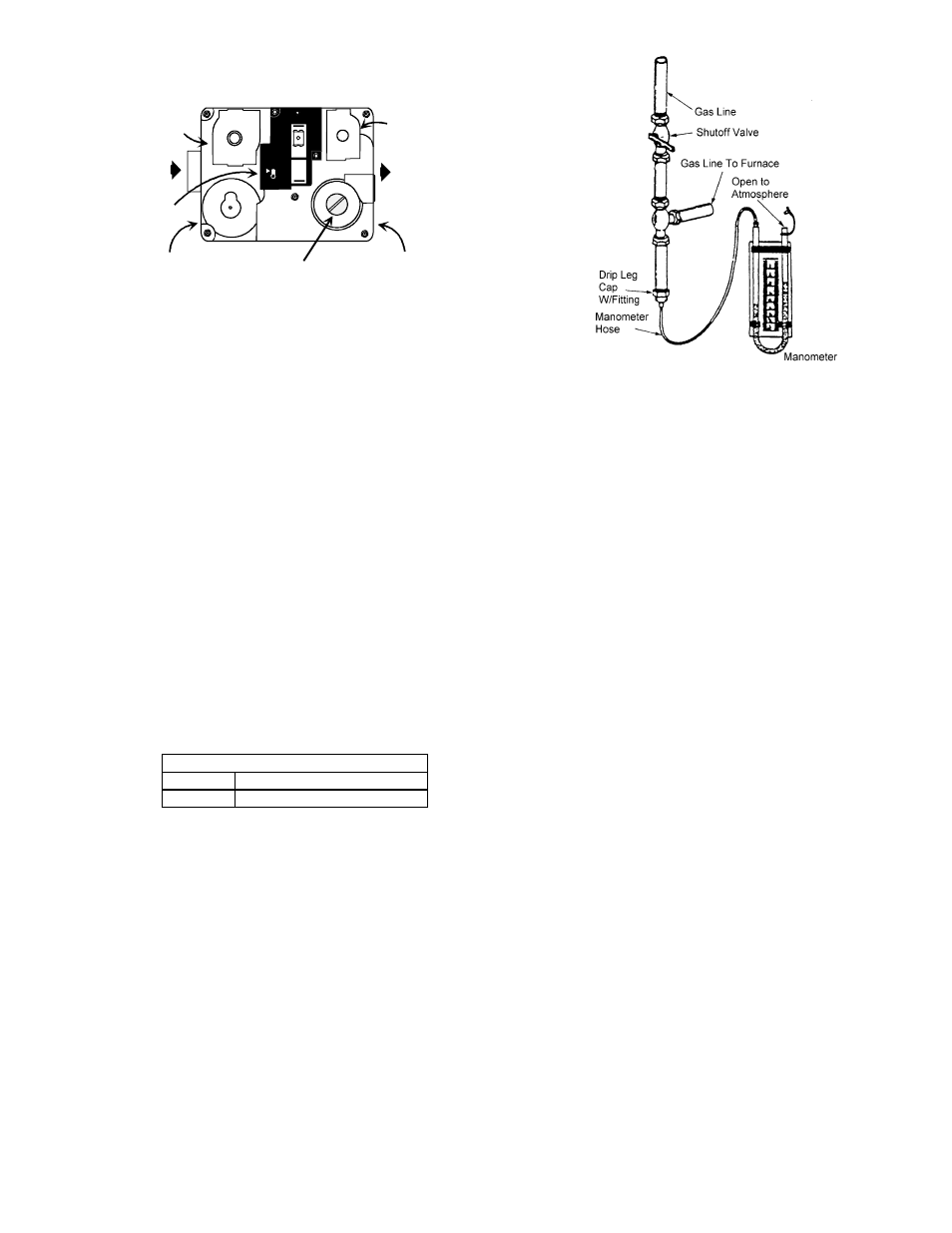

Honeywell Model VR8205, or White Rodgers Models

36E36 or 36E22, or Robertshaw Model 7222: Connect

a water manometer or adequate gauge to the “inlet

pressure tap” of the gas valve.

As an alternative method, inlet gas pressure can also

be measured by removing the cap from the drip leg and

installing a predrilled cap with a hose fitting (Figure 41).

With Power and Gas On:

2. Put furnace into heating cycle and turn on all other gas

consuming appliances.

Inlet Gas Pressure

Natural

Min. 5.0" W.C., Max. 10.0" W.C.

Propane

Min. 11.0" W.C., Max. 14.0" W.C.

Inlet Gas Pressure Must Not Exceed the Maximum Value Shown.

Figure 40

If operating pressures differ from above, make necessary

pressure regulator adjustments, check piping size, etc.,

and/or consult with local utility.

Figure 41

Measuring Inlet Gas Pressure

(Alternate Method)

CHECK MANIFOLD PRESSURE

A tapped opening is provided in the gas valve to facilitate

measurement of the manifold pressure. See the “Outlet

Pressure Tap” in Figures 36, 37, 38, & 39. A “U Tube”

manometer having a scale range from 0 to 12 inches of

water should be used for this measurement. The manifold

pressure must be measured with the burners operating .

To adjust the pressure regulator, remove the adjustment

screw or cover on the gas valve. Turn out (counterclockwise)

to decrease pressure, turn in (clockwise) to increase pres-

sure. Only small variations in gas flow should be made by

means of the pressure regulator adjustment. For natural

gas, the manifold pressure must be between 3.2 and 3.8

inches water column (3.5 nominal). For propane gas, the

manifold pressure must be between 9.7 and 10.3 inches

water column (10.0 nominal). Any major changes in flow

should be made by changing the size of the burner orifice.

CHECK GAS INPUT (NATURAL GAS ONLY)

To measure the gas input using the gas meter proceed as

follows:

1. Turn off gas supply to all other appliances except the

furnace.

2. With the furnace operating, time the smallest dial on the

meter for one complete revolution. If this is a 2 cubic

foot dial, divide the seconds by 2; if it is a 1 cubic foot

dial, use the seconds as is. This gives the seconds per

cubic foot of gas being delivered to the furnace.