X. start-up, adjustments, and checks, Caution, Figure 30 counterflow furnaces – Amana VR8205 User Manual

Page 21

21

9. After a 15 second delay while flue products are purged

from the furnace heat exchanger, the induced draft

blower motor is de-energized.

10. The air circulation blower has an adjustable delay-off

timing of 60, 90, 120 or 180 seconds (starting from the

time the gas valve closes). This allows more heat from

the furnace to be transferred to the conditioned space.

After this time has elapsed, the blower will be de-

energized.

NORMAL COOLING SEQUENCE - INTEGRATED

IGNITION CONTROL

With the room thermostat in the FAN-AUTO position, the

indoor air circulation blower and outdoor condensing unit

will be energized when a call for cooling occurs. When the

call for cooling ends, the outdoor condensing unit will be de-

energized. The indoor air circulation blower will continue to

run for 45 seconds.

OTHER ITEMS

Constant Fan. During normal operation, the air circu-

lation blower will continually run at “Cooling” speed as

long as power is present at terminal G. If a call for heat

occurs, the blower will run at heating speed throughout

the heating cycle.

If a trip on high/auxiliary/rollout limit occurs, the air

circulation blower will run at “Heating” speed. Even if

power is present at terminal G, the blower will run at

heating speed until the limit closes.

X. Start-Up, Adjustments, and Checks

GENERAL OPERATION

This furnace is equipped with an electronic ignition device

to light the burners and an induced draft blower to exhaust

combustion products.

An interlock switch prevents furnace operation if the blower

door is not in place. Keep the blower access doors in place

except for inspection and maintenance.

This furnace is also equipped with a self-diagnosing elec-

tronic control module. In the event a furnace component is

not operating properly, the control module LED will flash

on and off in a factory-programmed sequence, depending

on the problem encountered. This light can be viewed

through the observation window in the blower access door.

Refer to the

Diagnostic Signal Chart for further explanation

of the lighting codes and Section X,

Abnormal Operation -

Integrated Ignition Control for an explanation of the pos-

sible problem.

On new installations, or if a functional part such as the gas

valve, pressure switch, or limit control has been replaced,

verify that the furnace is operating properly after servicing.

Check furnace operation as outlined in the following in-

structions. If any sparking, odors, or unusual noises are

encountered, shut off electrical power and recheck for

wiring errors, or obstructions in or near the blower motors.

Various shipping materials must be removed before the

blower motor is operated.

CAUTION

To prevent personal injury, use only blunt

pointed screws to attach the plenum to the

furnace and filter rack. Screws should not

be placed where they could interfere with

filter replacement.

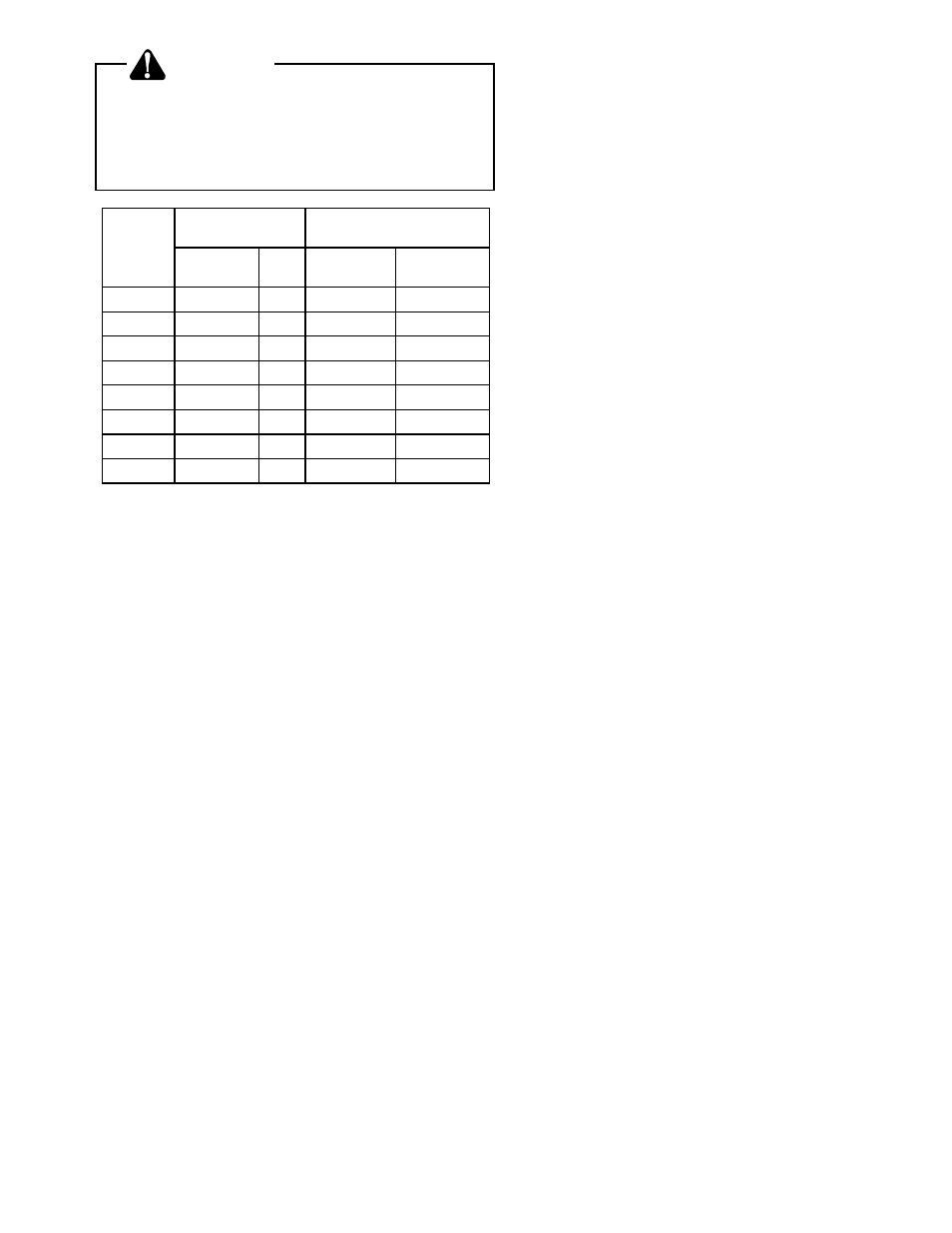

S iz e_ Air

Dim ension "A",

Inc he s

M inimum R e comme nded

F ilter Siz e s, Inches

F low

T hrow aw ay

Perm.

F iberglas s

T hrow aw ay

P erma ne nt

045_30

15-1/2

8

(2) 16x 20x 1

(2) 10x 20x 1

070_30

15-1/2

8

(2) 16x 20x 1

(2) 10x 20x 1

070_40

19-3/4

8

(2) 20x 20x 1

(2) 10x 20x 1

090_30

14-1/4

13

(2) 16x 20x 1

(2) 15x 20x 1

090_50

24-1/4

13

(2) 25x 20x 1

(2) 15x 20x 1

115_40

17-3/4

11

(2) 20x 20x 1

(2) 15x 20x 1

115_50

23-1/2

11

(2) 25x 20x 1

(2) 15x 20x 1

140_50

23-1/2

11

(2) 25x 20x 1

(2) 15x 20x 1

Figure 30

Counterflow Furnaces

3. With the air flow direction arrow pointing toward the

furnace, insert the filters from the left side of the blower.

Starting with the right filter, push the filter into the

plenum so the bottom of the filter fits into the filter rack

and the upper edge rests against the side of the

plenum. Repeat with the left filter (Figure 29).

OTHER FILTER OPTIONS

External filter grilles can be used instead of the filter rack.

IX. Sequence of Operation (Integrated

Ignition Control)

Refer to Timing Charts for sequencing.

NORMAL HEATING SEQUENCE

1. Thermostat calls for heat.

2. The induced draft blower is energized.

3. The ignitor is energized and is allowed to preheat for 17

seconds.

4. The gas valve is energized delivering gas to the burners

and starting combustion.

5. The control checks for a signal from the flame sensor

within seven seconds after the gas valve is energized.

Gas will only continue to flow if a signal is present.

6. The control waits 30 seconds and turns on the air

circulation blower to the speed that was selected for

heating operation.

7. The thermostat is satisfied and opens.

8. The control de-energizes the gas valve.