ROTHENBERGER COLLINS CLASSIC 22 A User Manual

Page 30

28

ENGLISH

5.3

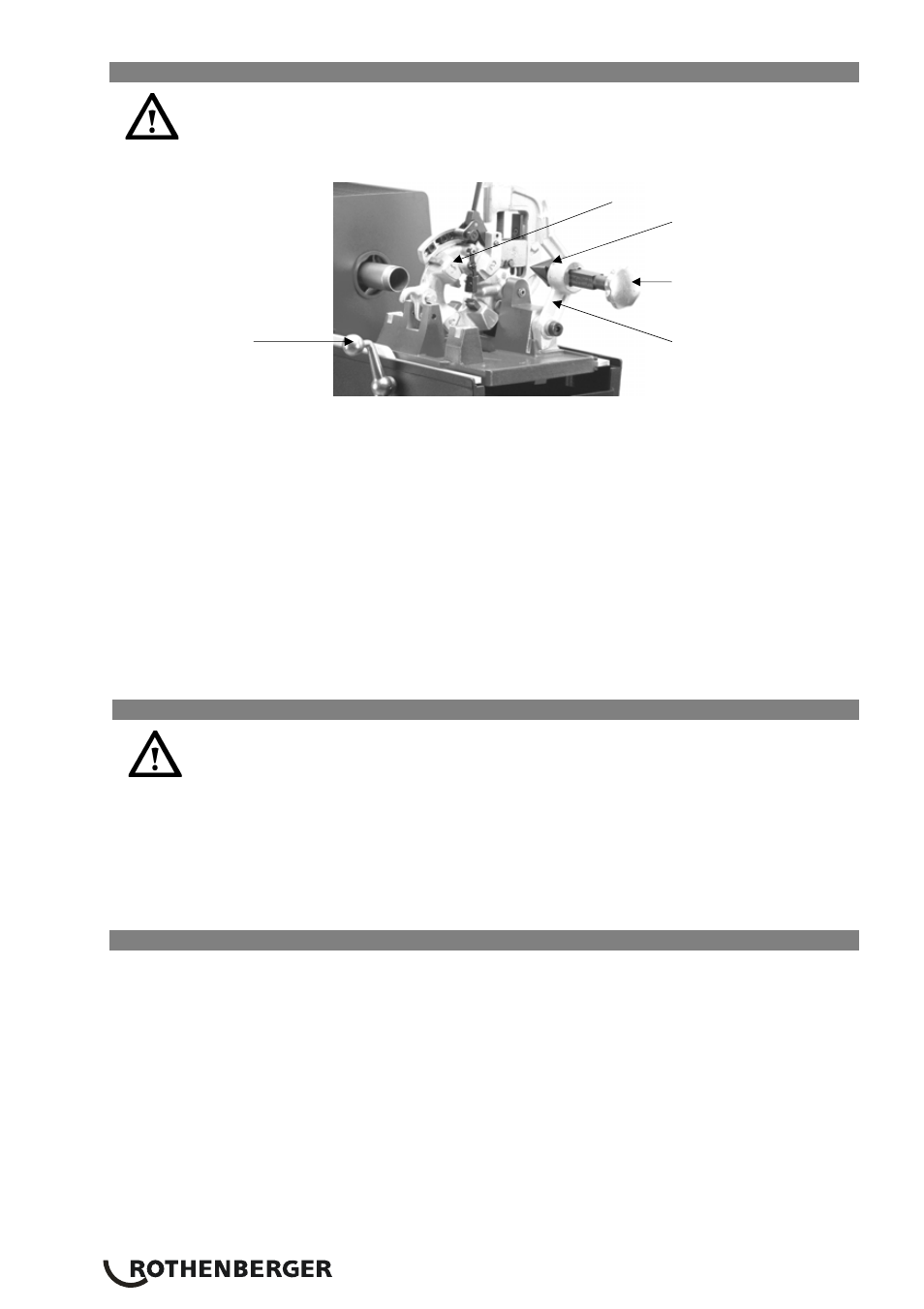

Reaming the workpieces

The cutting tip of the internal deburrer is very sharp! Do not touch it with

bare hands! Risk of cutting and injury!

Î

Swing reamer holder down (1) and insert a pipe if there is not already one in the machine

before separation.

Î

Raise cutter and die head (4).

Î

Reamer can be extended toward to pipe, if necessary, by sliding reamer knob (2) toward

reamer arm until contact with reamer holder. Twist reamer knob to left ¼ turn to lock in

position.

Î

With pipe chucked and rotating, turn carriage handle (6) counter clockwise so that flutes of

reamer enter pipe.

Î

Momentarily apply pressure to handle to force reamer against pipe to remove burrs.

Î

After reaming, retract reamer (3) and turn T.O.R.-switch to off. Place reamer in out of way

position.

5.4

Removing and installing the thread jaws from and in the thread-head

Wear gloves in order to prevent cut injuries to the hands caused by the

thread jaws!

After changing the thread- jaws, check that they are secure!

After changing the thread- head or replacing the thread- jaws, check that they are

locked securely in the tool carriage!

Precise thread- is only possible if the number on the slot of the thread- head

corresponds with the number on the thread jaw!

5.4.1 Automatic thread- head

B

The automatic die head requires two sets of dies to thread pipe ranging from ½” through 2”.

One set of dies is required for each of the following pipe size ranges:

½” and ¾ , and 1” through 2”. Bolt threading requires a separate set of dies for each bolt

size.

Î

Make sure trigger assembly (1) is released

Î

Disengage selector pin (2) and swing it up, out of the way.

Î

Lay head down with numbers up.

Î

Rotate selector size bar (3) to open position.

Î

Remove die segments No. 1, 3 and 4. Move die segment No.2 until die pin can freely travel

in outer scroll slot.

2

3

1

4

6