Safety of the installation, Water temperature protection, Flue gas backflow safeguard – A.O. Smith ADM - 80 User Manual

Page 13: Flame probe

Instruction manual ADM

13

gis

2.4.2

Water temperature protection

By means of the frost, high-limit and safety thermostats, the burner control

monitors three temperatures that are important for safety. The table explains the

working principle of the thermostats with sensors.

Temperature protection

2.4.3

Flue gas backflow safeguard

The flue gases are discharged to the outside via the draught diverter (33) and

the flue (22). To prevent the flue gases from flowing back into the boiler room,

the discharge ducting is monitored by a feature called the Thermal Reflux

Safeguard (TRS). This uses a flue gas thermostat (37) with a flue gas

thermostat sensor (34) that are located in the draught diverter. Under normal

circumstances this sensor will register the ambient temperature.

However, if the chimney is not drawing sufficiently (for example, due to a

blockage in the chimney), the flue gases will 'reflux' and flow back past the flue

gas thermostat sensor. The sensor will then detect an excessive temperature

and the flue gas thermostat will open. The demand will cease, and the burner

control will immediately stop the heating cycle. The flue gas thermostat will also

lock out. It must be manually reset before the appliance can resume operation .

2.4.4

Flame probe

To ensure that no gas can flow when there is no combustion, the water heater

is fitted with a flame probe (21). The burner control uses the ionisation-detecting

properties of this probe for flame detection. The burner control closes the gas

valve the instant it determines that there is a gas flow but no flame is present.

2.5

Safety of the

installation

In addition to the appliance's standard built-in safety monitoring, the appliance

must also be protected by an expansion vessel, expansion valve, pressure

reducing valve, non-return valve and a T&P valve.

The use of an expansion vessel, expansion valve and/or pressure reducing

valve depends on the type of installation: unvented or vented.

2.5.1

Inlet combination and pressure-reducing valve

In addition to the appliance's standard built-in safety monitoring, the appliance

must also be protected by an expansion vessel, expansion valve, pressure

reducing valve, non-return valve and a T&P valve.

The use of an expansion vessel, expansion valve and/or pressure reducing

valve depends on the type of installation: unvented or vented.

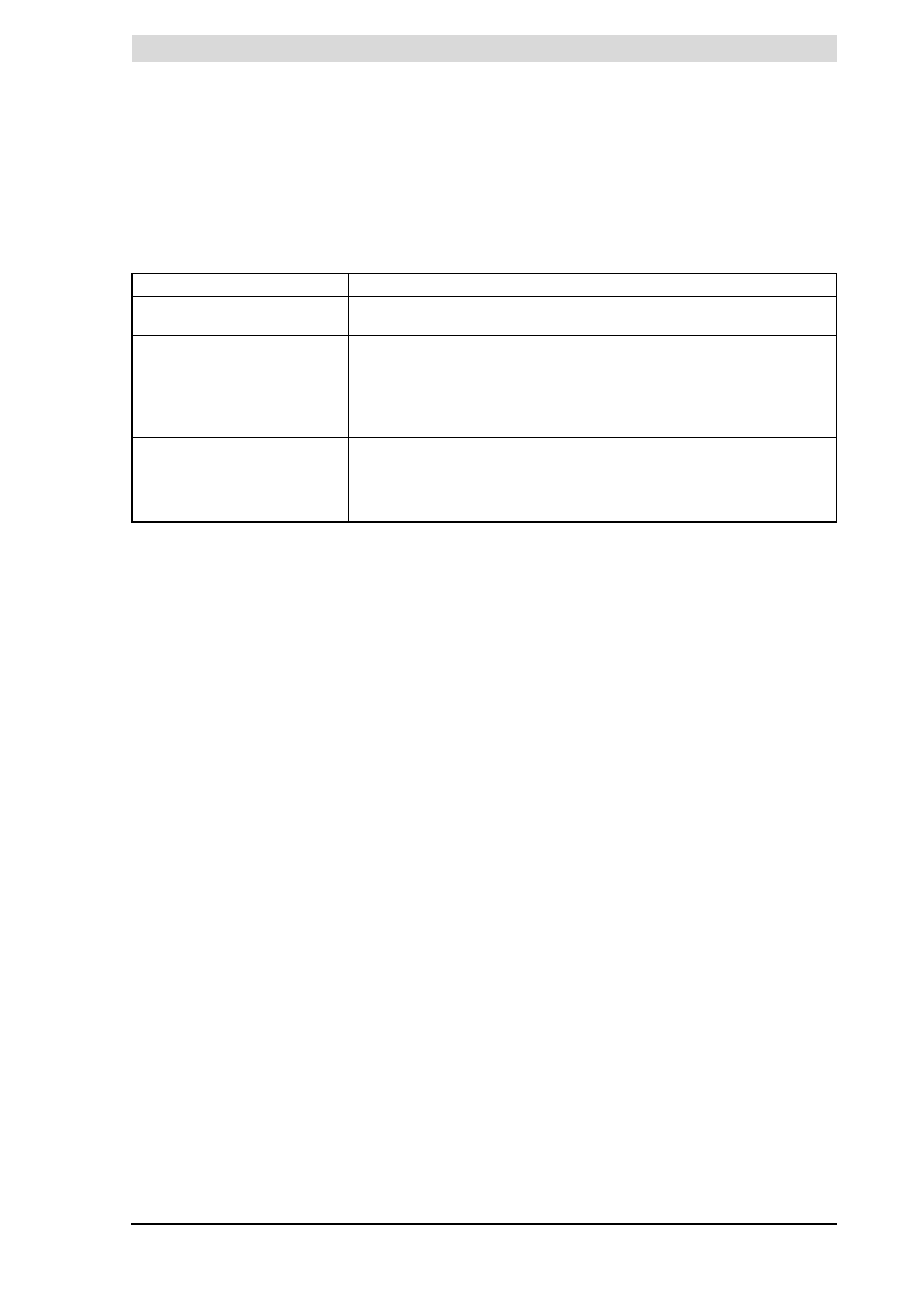

Protection

Description

Frost thermostat

When the frost thermostat sensor (46) measures a temperature of 20°C or

less, the heating cycle

(2.3 "The appliance's heating cycle")

will start.

High-limit thermostat

When the high-limit thermostat sensor (39) measures a temperature higher

than 84°C, the high-limit thermostat will open. The heat demand is terminated

and the burner control halts the heating cycle until the high-limit thermostats

close once more. At that moment the burner control will reset the appliance and

the heating cycle will restart. The high-limit safeguard serves to prevent

overheating and/or excessive formation of scale in the appliance.

Safety thermostat

When the safety thermostat sensor (38) measures a temperature higher than

93°C, the safety thermostat will open. The heat demand is terminated and the

burner control will immediately halt the heating cycle. The burner control will go

into a lockout error state. This must be manually reset before the appliance can

resume operation.