Quarterly – Alliance Laundry Systems Hardmount Coin and OPL User Manual

Page 19

Maintenance

17

F232134

© Copyright, Alliance Laundry Systems LLC – DO NOT COPY or TRANSMIT

7. Use compressed air to clean lint from motor.

8. Clean interior of machine, both basket and shell,

by wiping with a water-soaked sponge or cloth.

9. Use compressed air to clean all electrical

components of moisture and dust.

10. Verify the insulation is intact on all external wires

and that all connections are secure. If bare wire is

evident, call a service technician.

Quarterly

NOTE: Disconnect power to the machine at its

source before performing the quarterly

maintenance procedures.

1. Tighten door hinges and fasteners, if necessary.

2. Using a Teflon-based spray lube, lubricate the

door lock by applying the spray to the door lock

pin while turning the door handle.

3. Tighten anchor bolts, if necessary.

4. Verify that the drain motor shield is in place and

secure, if so equipped.

5. Check all painted surfaces for exposed metal.

(Matching paint is available from the

manufacturer.)

●

If bare metal is showing, paint with primer or

solvent-based paint.

●

If rust appears, remove it with sandpaper or by

chemical means and then paint with primer or

solvent-based paint.

6. Clean customer-supplied steam filter, where

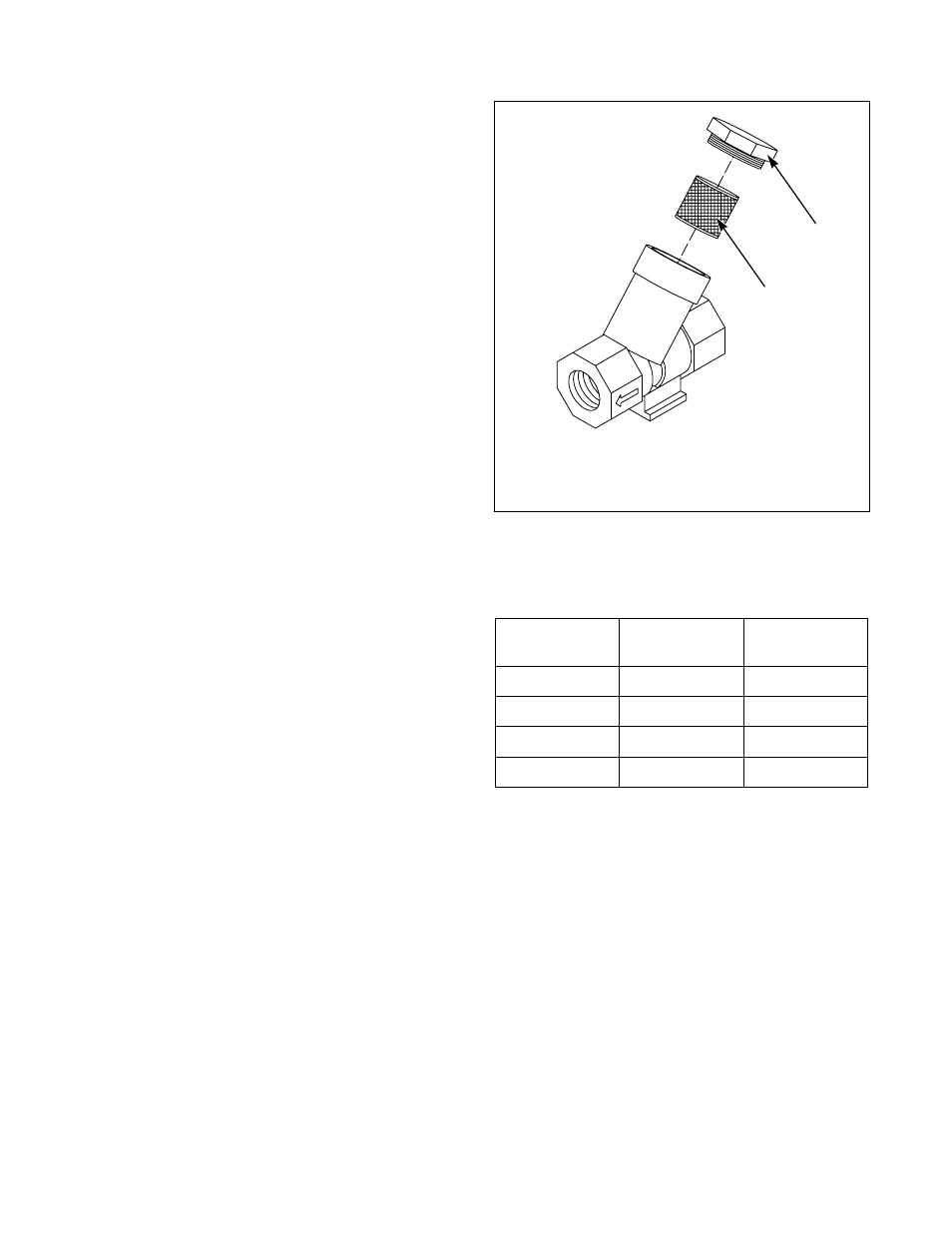

applicable. Refer to Figure 13.

a. Turn off steam supply and allow time for the

valve to cool.

b. Unscrew Cap.

c. Remove Element and clean.

d. Replace Element and Cap.

Figure 13

7. Check the bearing mounting bolts to make sure

they are torqued properly. Refer to Table 2 for

specifications.

H042I

1

Cap

2

Filter Element

Machine

Capacity

Bearing

Torque

18-25

All

75 ft.-lbs.

27-60

All

105 ft.-lbs.

80

Front

200 ft.-lbs.

80

Rear

97 ft.-lbs.

Table 2

H042I

1

2