Operating instructions for face driver coe, Exchanging the carrier plate (3), Exchanging and setting the centring tip (2) – ROHM CoE - Constant face drivers User Manual

Page 4: Dismantling and mounting the support bolts, Maximum weight of work-piece, Maintenance

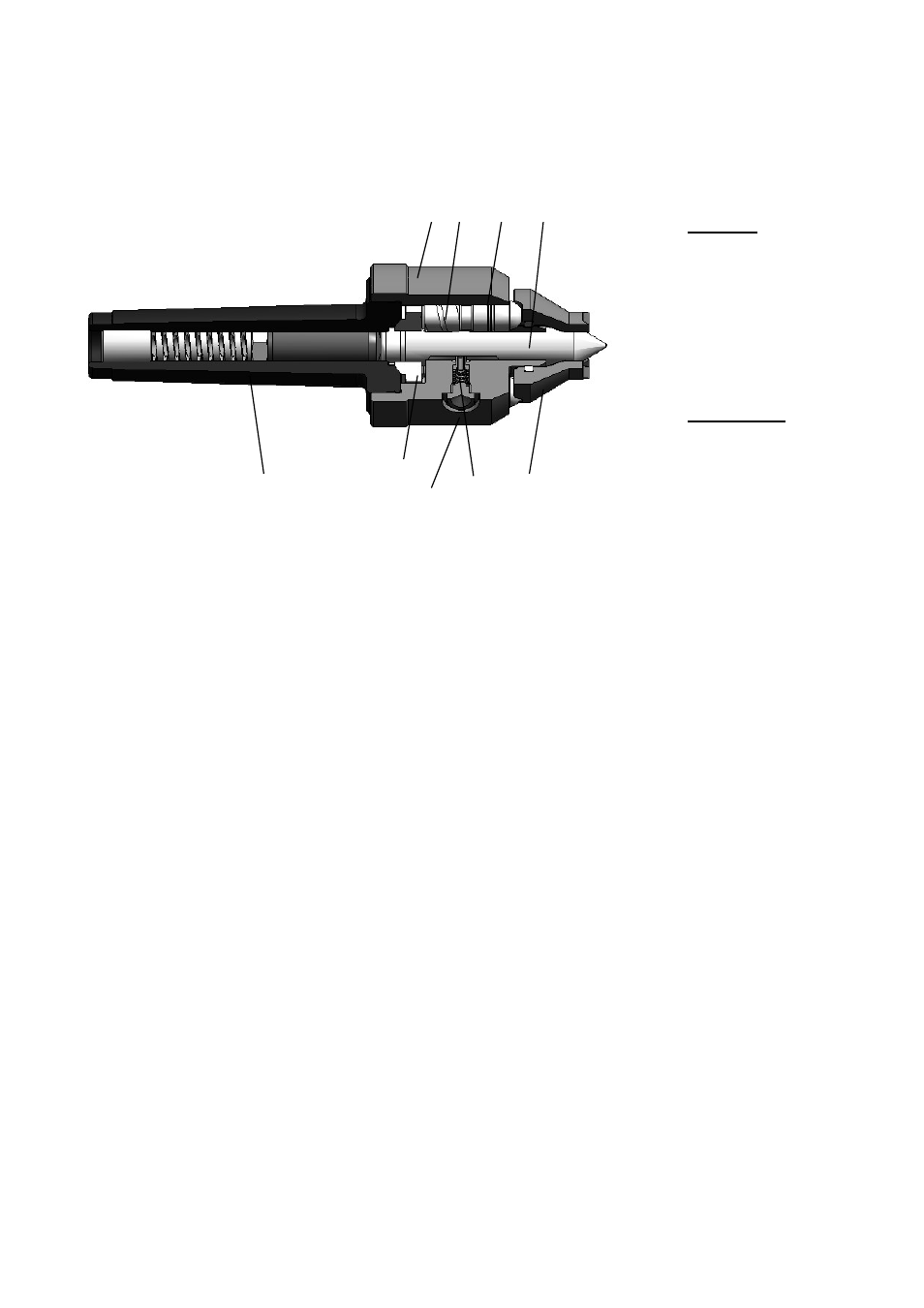

Operating Instructions for Face Driver CoE

With plug-in, radial freedom of movement driving discs

Features:

Turning and milling

in one setting

The suspended

centring tip facilitates

a longitudinal impact

point on the front side.

High level of

concentricity

(0.015mm)

Intended Use

Clamping circuit

Ø 8 – 80 mm

Work-piece

weight

max. 100 kg

Guide value for the

axially permitted

load of the support

bolts: 90kN

Order-No.

Order-No.

1 = body

1177540

6 = thrust piece

712526

2 = centring tip

7 = compensation disk

712524

3 = carrier plate

8 = funnel grease nipple

027380

4 = support bolts

1177542

9

=

O-ring

652312

5 = spring assembly

313026(MK3)

313251(MK4/MK5)

Exchanging the Carrier Plate (3)

Lever off the carrier plate (3) with a screwdriver.

Choose the biggest carrier plate (3) possible, as per the rotation Ø (note the direction of movement).

Grease the O-ring (9) and fit the carrier plate (3).

Here you must ensure that the support bolts (4) plunge into the grooves of the carrier plate (3).

Exchanging and Setting the Centring Tip (2)

Pull the centring tip (2) out to the front.

Choose an appropriate centring tip (2), grease it and slide it into the drill hole, making sure that the

spring thrust piece (6) rests in the groove of the centring tip (2).

Set the spring assembly (5) so that the centring tip (2) performs a stroke of 2 - 6mm when the work-piece

is clamped in. The spring assembly (5) can be adjusted axially at the shaft side using a hexagonal key

(Allen key).

Dismantling and Mounting the Support Bolts

Pull out the support bolts (4) when dismantling (thread M4).

Check O-ring (9), grease support bolts (4) and fit into the body (1).

Maximum Weight of Work-Piece

For base body MK3 and the model with set centring tip Ø4mm: work-piece weight max. 50kg

For base body MK4 and MK5: work-piece weight max. 100kg

Maintenance

Check the cutting edges of the carrier plates (3) regularly, replace carrier plates (3) in good time, or

change the hard metal carrier plates.

The hardened centring tip (2) can be resharpened if worn.

The centring tip (2) and support bolts (4) must be regularly greased using the funnel grease nipple (8).

Lubricant: ISO-Designation C GLP DIN 51502, viscosity class VG 220 DIN 51519

Check the free movement of the mechanical compensation of the support bolts (4).

1 4

9

2

3

6

8

7

5