Oven removal, Changing gas type, Table 1 – Siemens EG20158EU User Manual

Page 6

5 -

Mechanical joint/Universal joints.

Move the oven towards the universal joints.

be left so that the universal joints can be

manually connected to the oven. Remove

the gum or adhesive tape from all the

universal joints and connect them to the

6 -

Mounting the oven.

the 2 screws to secure it to the side walls

test.

The controls received with the oven with

the gas symbols must be placed on the

Switch on the gas of the cooking hob and

burners stay alight after switching them

on and releasing the control knobs.

(Thermocouple safety burners) Turn the

controls from maximum to minimum to

check the stability of the flame.

Oven removal:

If the oven needs to be removed to:

regulate the minimum point of the tap

fittings, adjust the length of the universal

joints or for a new mounting, the following

steps must be taken:

1 -

Remove the controls knobs.

Remove the oven mounting screws

(situated on both sides of the oven behind

the door, in front of the oven unit, side

walls).

50 mm. Only remove the oven the required

distance in order to access the rear part

of the control panel. If you continue to

remove the oven, the universal joints in

the tap fittings area may come loose.

actuators.

unit. If necessary (for example with a high

base board in the kitchen unit) it may be

necessary to remove the electrical

connection and the earth wire.

If the universal joint has come away from

the tap fitting or actuator spindle, it must

be refitted:

a) Securing the universal joint to the

actuator:

The position of the narrow and wide pivots

of the universal joint needs to be taken

into consideration.

b) If the plastic piece of the tap fitting

spindle falls off: reconnect it but take into

account the correct position of the spindle

with a "D" shape and tighten it firmly.

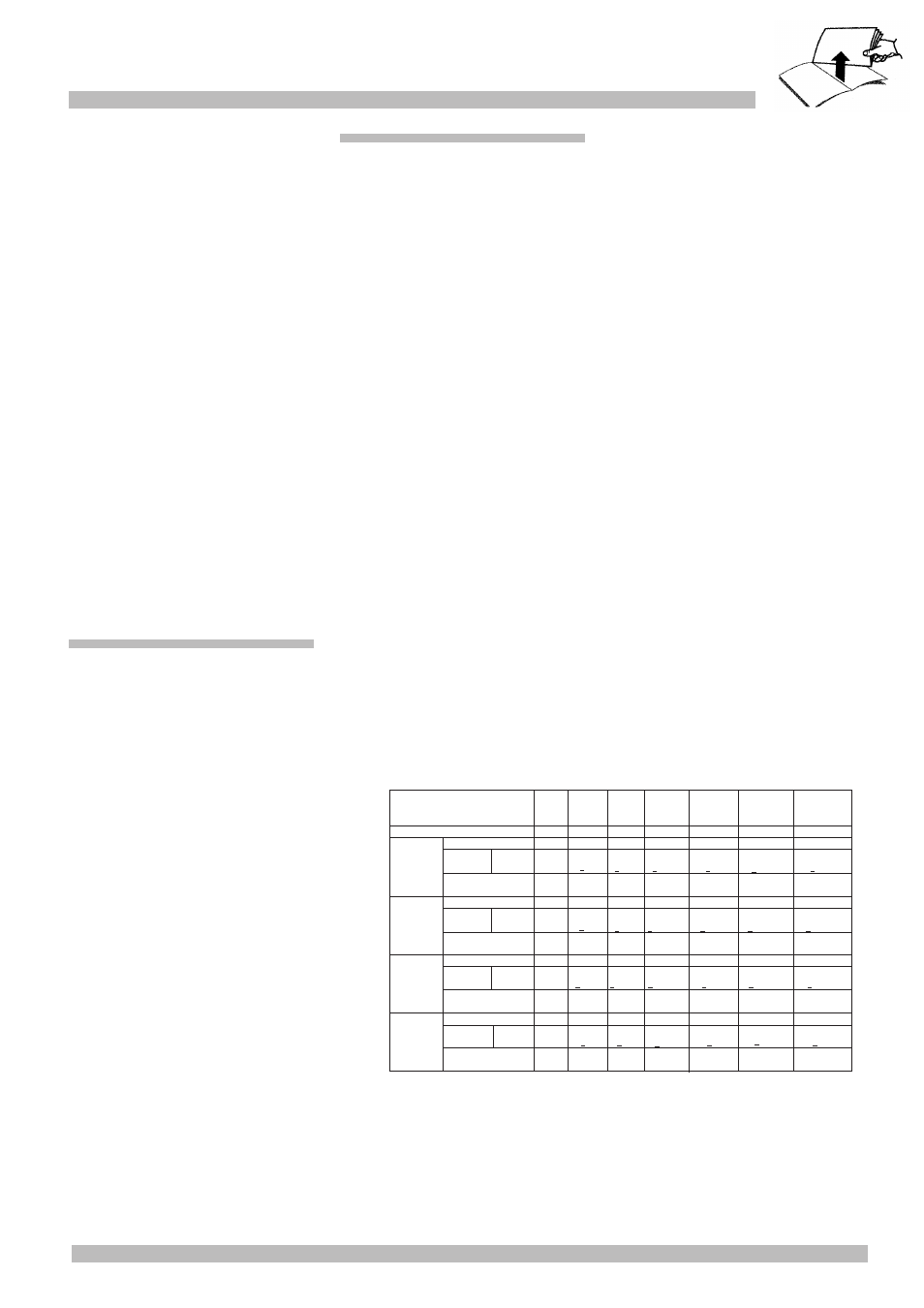

Changing gas type

Before connecting up the appliance to

the installation, first check that it has been

adjusted for the type of gas that is to be

supplied. Our cooking hobs leave the

factory set to function with the type of gas

that is indicated on the specifications plate.

legislation permits it, this cooking hob may

be adapted to function with other types of

gas. To do so, follow these steps:

A) Change of rapid, semi-rapid and

auxiliary burner tips.

1 -

Remove the pan supports, cover

and casing of the burner.

2 -

Change the burner tips using a 7

mm socket spanner and tighten them as

firmly as possible to ensure they are

With these burners the air does not have

to be adjusted.

B) Adjusting the reduced

consumption of the taps of the cooking

hob burners.

2 -

Remove the oven or control module

sequence.

array from its position in the tap shank.

well as ignition switches, the flow adjusting

screw must always be visible.

and bearing in mind that:

For 28-30/37 mbar Propane and

Butane Gas, the screw must be tightened

as firmly as possible.

For 50 mbar Butane Gas, change the

by-pass.

Place the sticker indicating that the

appliance's gas supply has been changed

close to the specifications plate.

actions, put the parts back together again.

Never take the tap spindle apart.

In

the event of a malfunction, change the

whole tap.

Put these instructions in a safe place for future reference

For Natural Gas, turn the screw

anti-

clockwise to the correct hotplate burner

gas output. The flame must be stable and

as small as possible. Check:

- the stability of the flame when changing

- the stability of the flame against draughts,

the hotplate burner setting between maxi-

mum and minimum,

- that there is no flame back draught.

7 -

Completion of installation and working

2 -

3

-

Remove the oven carefully, approx.

4

-

Remove the universal joints from the

5 -

Remove the oven from the kitchen

6

-

Special cases with the universal joints:

GAS

TYPE

G -31

PROPANE

G- 30

BUTANE

G -20

NATURAL

G -25

NATURAL

Gas pressure for use

Rapid

burner

Injector make

Consumption

(Hs)

Pressure 15ºC

1,013 mbar

Semi-rapid

burner

Auxiliary

burner

Triple flame

burner

m

3

/h

m

3

/h

m

3

/h

m

3

/h

g/h

g/h

g/h

g/h

mbar

kW

kW

kW

kW

37

85

3

-

214

67

1,75

-

125

50

1

0,33

71

97

3,6

1,26

-

257

-

29

85

3

0,6

-

218

67

1,75

-

127

50

1

0,33

73

97

3,6

-

261

-

20

115

3

0,5

0,286

-

100

1,75

0,167

-

72

1

0,33

-

140

3,6

0,343

0,095

-

3

0,5

0,333

-

1,75

0,194

-

1

0,33

-

3,6

0,399

0,111

-

Nominal

reduced

1,26

1,26

1,26

of gas that is indicated on the specifications

plate

Injector make

Consumption

(Hs)

Pressure 15ºC

1,013 mbar

Nominal

reduced

Injector make

Consumption

(Hs)

Pressure 15ºC

1,013 mbar

Nominal

reduced

Injector make

Consumption

(Hs)

Pressure 15ºC

1,013 mbar

Nominal

reduced

G -20

NATURAL

25

<

110

3

0,5

0,286

-

91

1,75

0,167

-

68

1

0,33

-

124

3,6

0,343

0,095

-

1,26

<

<

<

<

<

<

<

<

<

<

<

(see Fig. 9) A gap of approx. 50mm must

actuators. See Fig.9.

of the kitchen unit (Fig. 10).

spindles. Figure 11.

operate the burners. (Fig. 12). Check the

correctly sealed. Figure 13.

Figure 14, according to the disassembly

Figure 1 5 depending on the model

4

-

If the cooking hob has safety as

5

-

Operate the flow adjusting screw,

6

-

7

-

Once you have completed these

G- 30

BUTANE

3

0,6

-

218

1,75

0,35

-

127

1

0,33

73

3,6

-

261

-

1,26

<

<

<

0,6

0,6

50

74

58

43

75

0,5

20

132

100

0,5

73

150

0,5

<

<

<

<

<

<

<

<

<

1-

Set the taps to minimum.

3 -

Remove the 3 body universal joint

Push the oven right to the back and use

en

It is recommended that you call our

gas supply companies' specifications.

All installation, regulation and adaptation

respecting all applicable regulations,

by an authorised installation technician,

Technical Assistance Service for

and gas supply.

to other types of gas must be carried out

you begin, turn off the appliance's electricity

standards and the country's electrical and

adaptation to other types of gas. Before

The burners must be used with the type

TABLE 1

0,6

BURNER FEATURES

Provided that your country's domestic

Raise and secure the universal joints to

the bottom of the cooking hob with the

help of adhesive tape or gum, if the cooking

hob does not have this.

4 -

Electrical connection

Connect the oven to the mains.

The connection cable must be connected

to the oven and the earth wire secured as

oven in the kitchen unit.

shown in Fig. 8. If necessary, insert the