Ashcroft D700 - Differential Pressure Switches User Manual

Page 2

INSTALLATION

These controls are precision instruments and should never be

left with internal components exposed. After installation ensure

that covers are in place and conduit openings are closed.

MOUNTING D400 AND D700 SERIES

There are three holes external to the enclosures for surface

mounting. The locations of these holes is shown on the general

dimension drawing. The controls may also be mounted directly

on the pressure line using the pressure connections.

ELECTRICAL CONNECTIONS

Remove cover

D400 Series – two screws hold cover to enclosure

D700 Series – cover unscrews

CONDUIT CONNECTIONS

Note – It is recommended that Teflon

®

tape or other sealant be

used on conduit, bushing or plug threads to ensure integrity of

the enclosure.

D400 Series standard – one

3

⁄

4

NPT conduit hole right side.

D700 Series standard – two

3

⁄

4

NPT conduit holes with one

permanent plug.

NEMA 7 & 9 enclosures require proper conduit

seals and breathers as per the National Electrical Code.

D400 & WT700 Series – XJL variation – two

3

⁄

4

NPT conduit

holes with two

3

⁄

4

to

1

⁄

2

NPT reducing bushings.

D400 Series – XJK variation – two

3

⁄

4

NPT conduit holes.

D400 SERIES

SPDT – Wire directly to the switch according to circuit require-

ments. On controls with pilot lights, wire lights according to cir-

cuit diagram on the inside of the cover. See special wiring

instruction tag for single switches with two pilot lights and dual

switches with one or more pilot lights.

2-SPDT – Dual switching elements consist of two SPDT switches

mounted together in a bracket. The switches are calibrated to have

simultaneous operation within 1% of range either on increasing

or decreasing pressure, but not in both directions. Wire directly

to the front and rear switch according to circuit requirements.

Leads provided on rear switch and leads provided for hermeti-

cally sealed switch components are color coded as follows:

Common

– White

Normally Closed – Red

Normally Open

– Blue

See SPDT instructions for pilot light hook-up.

Installation and Maintenance Instructions for

D400 & D700 ASHCROFT

®

Snap Action

Switches for Differential Pressure Control

D700 SERIES

SPDT – Wire directly to the switch according to circuit

requirements.

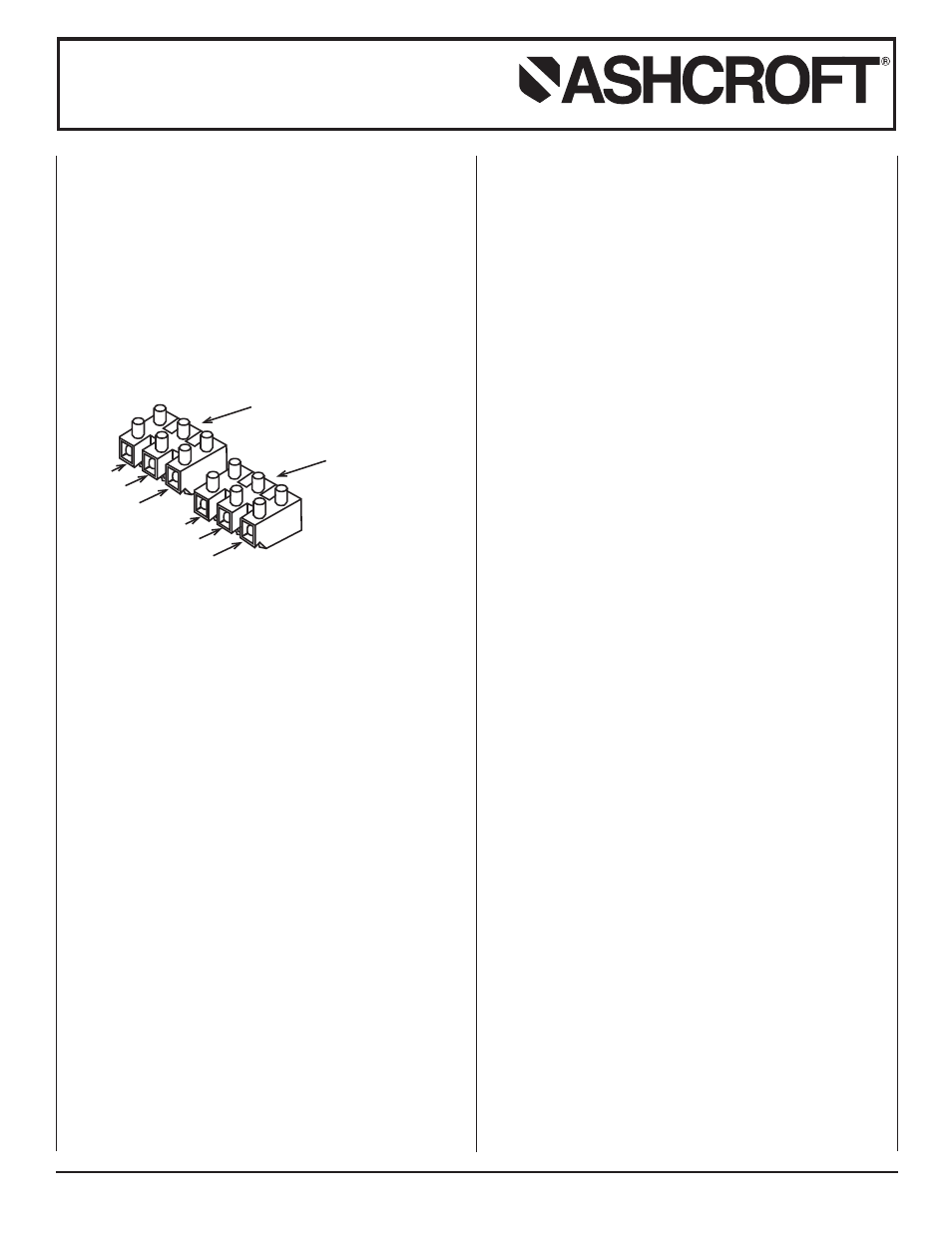

2-SPDT – Wire to front switch terminal block (left) and rear

switch terminal block (right) as marked. Strip insulation

5

⁄

16

˝,

insert in proper terminal connector and tighten clamping screw

to secure.

ADJUSTMENT OF SETPOINT

D400 & D700 Series – A single setpoint adjustment nut (

7

⁄

8

˝) is

located centrally at the bottom on the inside of the enclosure.

The direction of turning is indicated on a label affixed to the

inside of the control enclosure.

A typical calibration procedure would be as follows:

Static Working Pressure

– 600 psig

Adjustable Differential Range – 30/200 psid

Differential Setpoint

– 150 psi above static working

pressure

Simultaneously raise the high and low side pressure to 600

psig. Maintain the low side pressure at 600 psig. Raise the high

side pressure to 750 psig to obtain 150 psi differential.

Turn the adjustment nut until the switch changes mode at 150

psi differential. When the setpoint has been achieved, raise and

lower the high side pressure to ensure that the differential set-

point is correct.

D450 and D750 VARIABLE DEADBAND SWITCHES

Deadband is varied by rotating the wheel on the precision

switch. When viewed from the front of the enclosure, rotation to

the left increases deadband – rotation to the right decreases

deadband. Letters on the wheel may be used as a reference.

Deadbands obtainable will vary from 2% to 9% of pressure

range depending on range segment and the type of diaphragm.

ADJUSTMENT OF SETPOINT

As received, the differential pressure switch will normally be set

to approximately 90% of range. Rotate the wheel on the MICRO

SWITCH all the way to the right. This will provide the smallest

deadband. Pressurize the system to the required setpoint and

turn the adjustment nut until the switch changes mode. Lower

the pressure to reset the switch. Rotate the wheel on the

MICRO SWITCH until the desired deadband is obtained. The

upper setpoint will be changing upward with this adjustment.

Lower the pressure to reset the switch. Increase the pressure to

the desired setpoint and turn the adjustment nut until the switch

changes mode. Lower the pressure and check the reset point

and deadband.

Note – As indicated above, adjustment of setpoint is made by

use of

7

⁄

8

˝ nut. The precision switch element mounting screws

and bracket adjusting screw are factory sealed and should not

be tampered with.

© 2012 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614-5145, USA, Tel: 203-378-8281, Fax: 203-385-0499, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M009-10007- (250-2248E) 10/12

TERMINAL BLOCK

FRONT SWITCH

TERMINAL BLOCK

REAR SWITCH

NC

NO

C

NC

NO

C