Snap action switches – Ashcroft B700 Pressure Switches User Manual

Page 4

Installation and Maintenance Instructions for

B700 ASHCROFT

®

Snap Action Switches

© Ashcroft Inc., 250 East Main Street, Stratford, CT 06614 USA, Tel: 203-378-8281, Fax; 203-385-0408, www.ashcroft.com

All sales subject to standard terms and conditions of sale. I&M009-10120-10/02 ATEX Rev. 06/13

1. Installation Requirements

• Ambient Temperature: –20 to 60°C

• Process Temperature: – 20 to 60°C

Other temperature limits are possible with different

diaphragm materials

• Refer to appropriate datasheet for materials of construction

and technical information.

• These controls are precision instruments and should never

be left with internal components exposed. During installation

insure that covers are in place and conduit openings are

closed except when actually working on the control.

• To minimize the risk of injury, the control must be installed

according to the required safety and electrical codes.

• To attain the degree of protection listed on the switch it may

be necessary to add required conduit fittings.

• The switch must be protected from moisture, shock and/or

extreme vibration.

• Mounting position: Switch can be mounted in any position. It is

recommended that unit be set in intended operating poistion.

2. Cautions

• Always install the cover after wiring the switch and before

power is supplied.

• Before removing the cover in hazardous areas be sure there

is no explosive atmosphere present and the power supply is

turned off.

• For ATEX approved switches all safety locking devices and

electrical earthing must be installed or connected before

operating.

• Never carry a temperature switch by holding only the stem,

bulb or capillary.

• Do not push any foreign objects (ex. Screwdrivers) against

the diaphragm.

• Do not exceed ranges, current and/or voltage limits.

3. Mounting

• Three holes external to the enclosure for surface mounting.

Location of these holes is shown in the general dimension

drawing.

• Units may also be mounted directly on the pressure line

using the pressure connection. When tightening control to

pressure line, always use the wrench flats or hex on the

lower housing.

4. Electrical Connections

• Before operating the switch all conduit entries and/or junction

boxes need to be closed according to the required safety and

electrical codes.

a) Standard product has two

3

⁄

4

NPT conduit holes with one

permanent plug.

3

⁄

4

NPT conduit holes can be modified

or reduced with ATEX approved adapters.

b) Available ATEX approved cable glands can be used.

• It is recommended that Teflon tape or other sealant be used

on conduit, bushing, gland or plug threads to ensure integrity

of the enclosure.

5. Cleaning

• Never use aggressive solvents.

• Do not use high-pressure water to clean the switch.

6. Maintenance/Troubleshooting

• All ASHCROFT switches require little or no maintenance.

• Be sure that the case is closed at all times.

• When the switch is exposed to process media that may hard-

en and/or build up in the pressure port, the switch should be

removed and cleaned as needed.

• If the switch does not function, only trained and skilled per-

sonnel should check on the wiring, power supply and/or

mounting.

• If the problem cannot be solved, please contact one of the

Dresser affiliates or distributors.

7. Electrical Connections

• Only trained and skilled personnel are allowed to install the

wires to the electrical terminals of the switch.

• Cable couplers, glands and conduit connectors must have

the correct electrical approvals.

• Always follow safety and electrical regulations when connect-

ing these devices.

• The system ground of the device is marked with a green col-

ored screw and/or by the ground symbol.

• ATEX approved switches have and external ground screw

that must be connected.

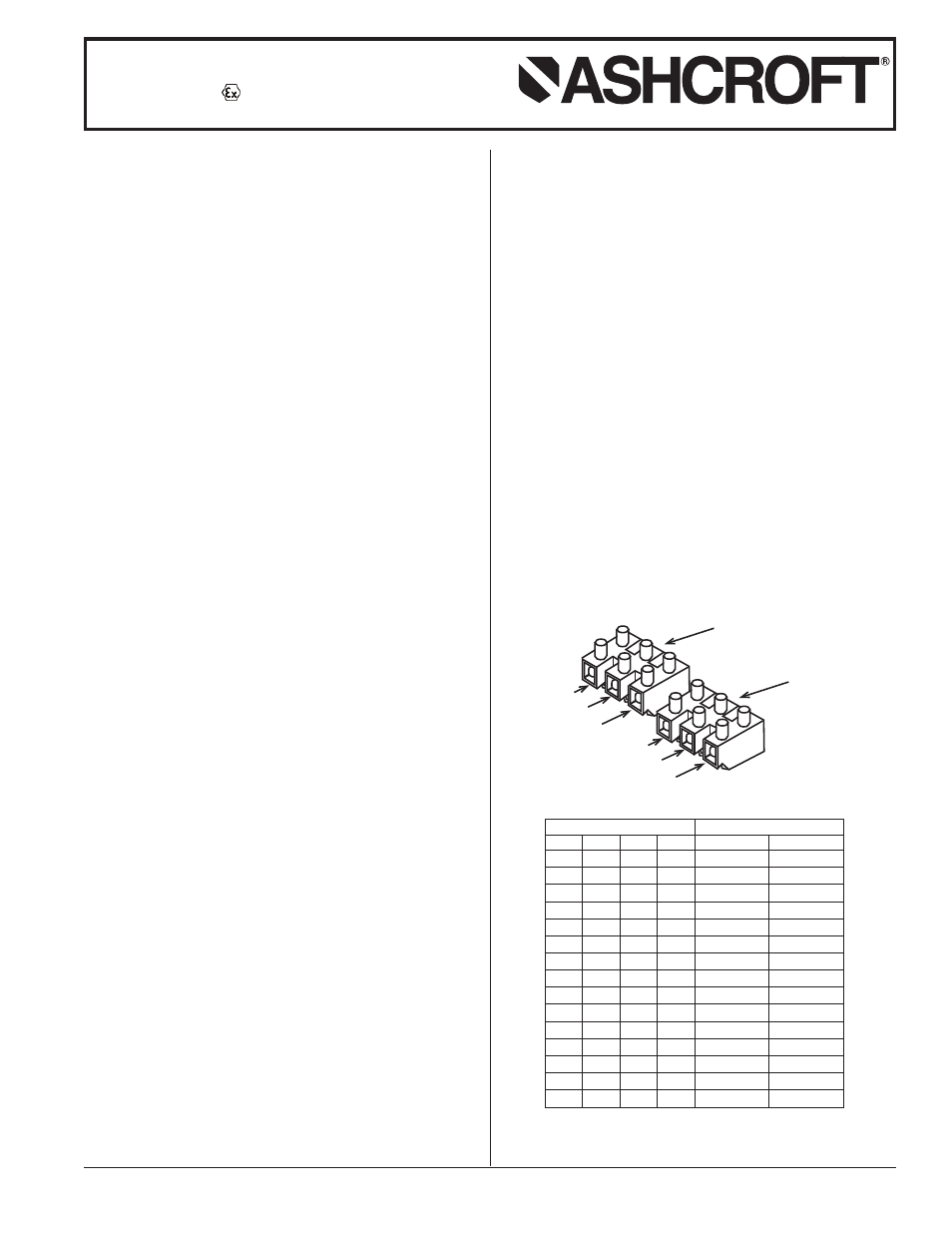

• Micro switch terminals and wire color codes:

TERMINAL BLOCK

FRONT SWITCH

TERMINAL BLOCK

REAR SWITCH

NC

NO

C

NC

NO

C

MICRO SWITCH CODE

ELECTRICAL RATING

Single

Dual

Single

Dual

Vac

Vdc

K

KK

20

61

15A, 250V

0.4A, 120V

W

WW

21

65

5A, 250V

P

PP

22

67

5A, 250V

2.5A, 28V

C

N/A

23

N/A

22A, 250V

G

GG

24

64

15A, 480V

0.25A, 250V

S

N/A

25

N/A

10A, 250V

10A, 250V

F

FF

26

62

15A, 250V

0.4A, 120V

Y

YY

27

63

15A, 250V

U

UU

28

N/A

15A, 250V

E

EE

29

N/A

15A, 250V

M

MM

31

70

1A, 250V

50mA, 60V

J

JJ

32

68

11A, 250V

5A, 30V

L

LL

42

71

1A, 125V

N/A

N/A

50

N/A

15A, 250V

H

HH

35

N/A

10A, 250V

0.3A, 250V

TABLE 1: MICRO SWITCH ELECTRICAL RATINGS

SIRA 02ATEX1391X; II 2GD; Ex d IIC T6 Gb;

Ex t IIIC T85° C Db IP 6X; (Ta = –20°C to +60°C)