Ashcroft GL42 - Low Differential Indicating Pressure Transmitter User Manual

Page 2

b. Design and mode of operation

The transmitter is based on a capacitance sensor element

with a micro machined differential capacitor using a patented

silicon-on-glass technology. This ultra-thin single crystal dia-

phragm provides excellent sensor repeatability and stability.

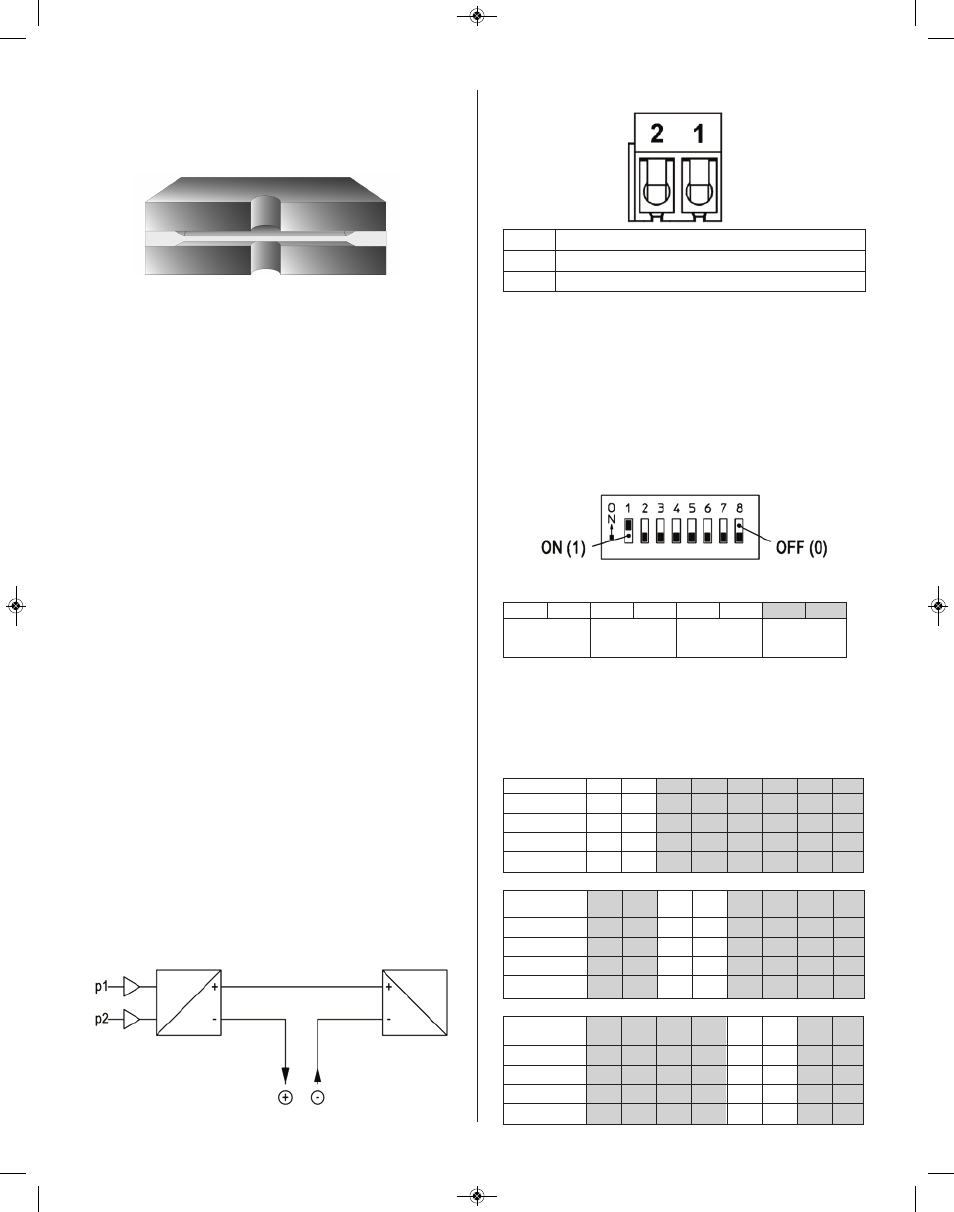

Sensor cross section

The silicon diaphragm sensor has no glues or other organics

to contribute a drift or mechanical degradation over time.

12. INSTALLATION AND ASSEMBLY

All supply lines should be arranged so that there are no me-

chanical forces acting on the device.

The GL42 is calibrated for vertical installation; however any

installation position is possible. If an installation position

other than vertical is selected, the zero-point signal can be

corrected as shown in Section 13b.

a. Process connection

• By authorized and qualified personnel only.

• All lines need to be depressurized when the instrument

is being connected.

• Appropriate steps must be taken to protect the device

from pressure surges.

• Check the suitability of the device for the media to be

measured.

• Maximum pressures shall be observed.

• Check that all connections are tight before use.

The pressure sensing lines need to be kept as short as pos-

sible and installed without sharp bends to avoid interfering

delay times.

The pressure connections are marked with (+) and (-) sym-

bols on the device. For differential pressure measurements,

the higher pressure is connected to the (+) side and the lower

pressure to the (-) side of the device.

If during installation the pressure measuring lines are already

under pressure, the zero-point cannot be checked and no

settings can be adjusted. In these cases, the device should

only be connected electrically first.

b. Electrical connection

• By authorized and qualified personnel only.

• The electrical connection of the device shall be per-

formed according to local electrical codes

• Turn off power before connecting the device.

i. 2-wire circuit

ii. Pin assignment

13. COMMISSIONING

All electrical supply, operating and measuring lines, and the

pressure connections must have been correctly installed be-

fore commissioning. All supply lines are arranged so that

there are no mechanical forces acting on the device.

Check that the pressure connections do not leak before

commissioning.

a. Configuration of the LCD display

To configure the LCD display, remove the lid by unscrewing

the four screws on the front of the device. This gives you ac-

cess to the DIP switch used for configuration.

The following overview shows the basic function of the indi-

vidual switches:

Using the following switch settings, the display can now be

configured at your discretion. Changes to the configuration

via the DIP switch are shown immediately on the display.

A “1” equals the switch setting “ON”; a “0” means that the

switch setting is “OFF”.

Pin

Signal Name

1

+ Power Supply / Output Signal +Ub / +Sig

2

- Power Supply / Output Signal -Ub / -Sig

S1

S2

S3

S4

S5

S6

S7

S8

Unit

Decimal

Attenuation

reserved

Point

Unit

S1

S2

S3

S4

S5

S6

S7

S8

inWC

0

0

X

X

mbar

1

0

X

X

kPa

0

1

X

X

Pa

1

1

X

X

Decimal

Point

S1

S2

S3

S4

S5

S6

S7

S8

0

0

0

X

X

1.0

1

0

X

X

2.00

0

1

X

X

3.000

1

1

X

X

Display

Damping

S1

S2

S3

S4

S5

S6

S7

S8

none

0

0

X

X

1 s

1

0

X

X

3 s

0

1

X

X

5 s

1

1

X

X

GL42

Meter

Power

Supply

I&M011-10227 (GL42)_GL42 I&M 6/25/14 10:29 AM Page 2