Ashcroft DXLdp - Differential Pressure Transmitter User Manual

Page 2

MODEL DXLdp DIFFERENTIAL

PRESSURE TRANSMITTER

OPERATING & INSTRUCTION SHEET

+

–

+

–

POWER

SUPPLY

+

–

POWER

SUPPLY

R

S

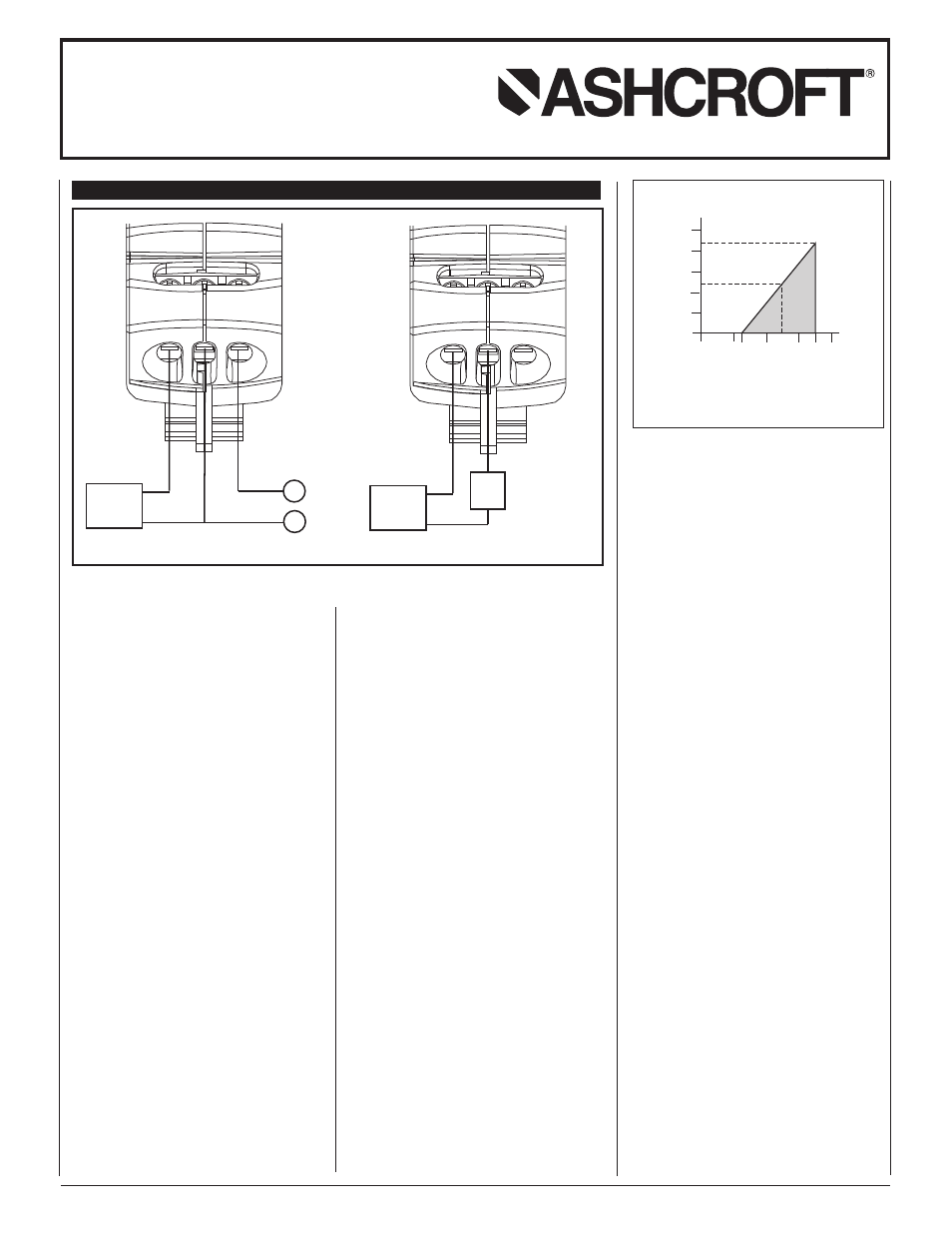

ELECTRICAL CONNECTIONS

Current Output

Voltage Output

Drawing #2

Vmin = 12V+ [.022A*(R L)]

*includes a 10% safety factor

RL = RS + RW

RL = Loop Resistance (ohms)

RS = Sense Resistance (ohms)

RW = Wire Resistance (ohms)

Load Limitations 4-20mA Output

0

10 12

20

30

36

40

1250

1091

1000

750

500

250

0

545

24

Drawing #3

Loop Resistance (

Ω

)

© 2011 Ashcroft Inc., 250 East Main Street, Stratford, CT 06614, USA • Tel: 203-378-8281, Fax: 203-385-0402 • email: [email protected], www.ashcroft.com. All specifications subject to change without

notice. All sales subject to standard terms and conditions of sale I&M011-10074 Rev A 5/11

ASHCROFT, INC.

250 EAST MAIN STREET, STRATFORD, CT 06614

TEL: 203-378-8281 • FAX: 203-378-0499

EMAIL: [email protected]

www.ashcroft.com

OPTION: SPOOLCAL™ (XPV)

The rotating process valve actuator in conjunction

with the SpoolCal™ actuator tool provides two

types of tests including Calibrate (CAL) and

Monitor (MON) through the appropriate Hi and Lo

Port of the SpoolCal actuator tool. In the (CAL)

mode the DXLdp is isolated from the process and

allows externally generated test pressure input for

calibration. In the (MON) mode the system pres-

sures can be monitored with an Ashcroft ATE

Calibrator or other handheld instrument without

physically unplugging the process tubes. In this

mode an on-line measurement can be captured. In

conjunction with the (XDL) option, a reference sig-

nal can also be captured without process interrup-

tion.

The (XPV) option supplies a SpoolCal™ actuator

tool and 7˝ of silicon tubing. The actuator tool

identifies the above positions and tests, including

high (HI) and low (LO) differential pressure reference.

From the (OFF) position the SpoolCal™ actuator

tool can be inserted and removed. The following

tests can be performed:

Calibration (CAL):

Both zero and Span adjustment pots are non-

interactive and accessible from the front of the unit.

Note: Due to the sensing technology used rarely

are actual zero and span adjustments needed.

Zero and span pots are available on the basic unit.

Requires XDL and XPV options.

• Insert SpoolCal™ actuator tool.

• A 90-degree clockwise rotation isolates the

DXLdp from the process.

• Apply zero pressure. This can be best produced

by shorting the HI and LO ports on the SpoolCal™

actuator tool using the silicon tubing supplied.

Verify or make zero adjustment.

• An external pressure generator can be used to

produce the required span pressure. Verify or

make span adjustment.

• Measure record signal via front access test jacks,

option (XDL).

Monitor (MON):

Provides on line or uninterrupted measurement

point capability when XPV option is again selected

in combination with the (XDL) option, including

the front access test jacks.

• Insert SpoolCal™ actuator tool

• A 90-degree counterclockwise rotation tee’s the

process to both the DXLdp sensor and out

through the SpoolCal™ actuator tool, to provide

external measurement or recording capabilities.

OPTION: 2:1 TURN DOWN (X21)

Provides optional in field scalability via internal

jumpers.

Example: Given a 1.0˝ DXLdp with 4-20mA output.

The unit can be adjusted to operate full scale at

0.5˝. In addition, the 4-20mA reference output

remains in calibration.

Steps (Following instructions on label):

1. Lay unit on right side. Remove reusable left side

label.

2. Pry off access door and discard.

3. Using needle nose pliers or twisters, move

jumper from top to bottom position.

4. Reattach label.

5. Reverse range label on face of unit.