General dimensions for model cxldp (in inches), I.d. tubing. (see figure 5) when, Zero and span potentiometers – Ashcroft CXLdp - Differential Pressure Transmitter User Manual

Page 2

MODEL CXLdp DIFFERENTIAL

PRESSURE TRANSDUCER

INSTALLATION & MAINTENANCE SHEET

1.45

2.90

я .20

я .16

3.33

1.89

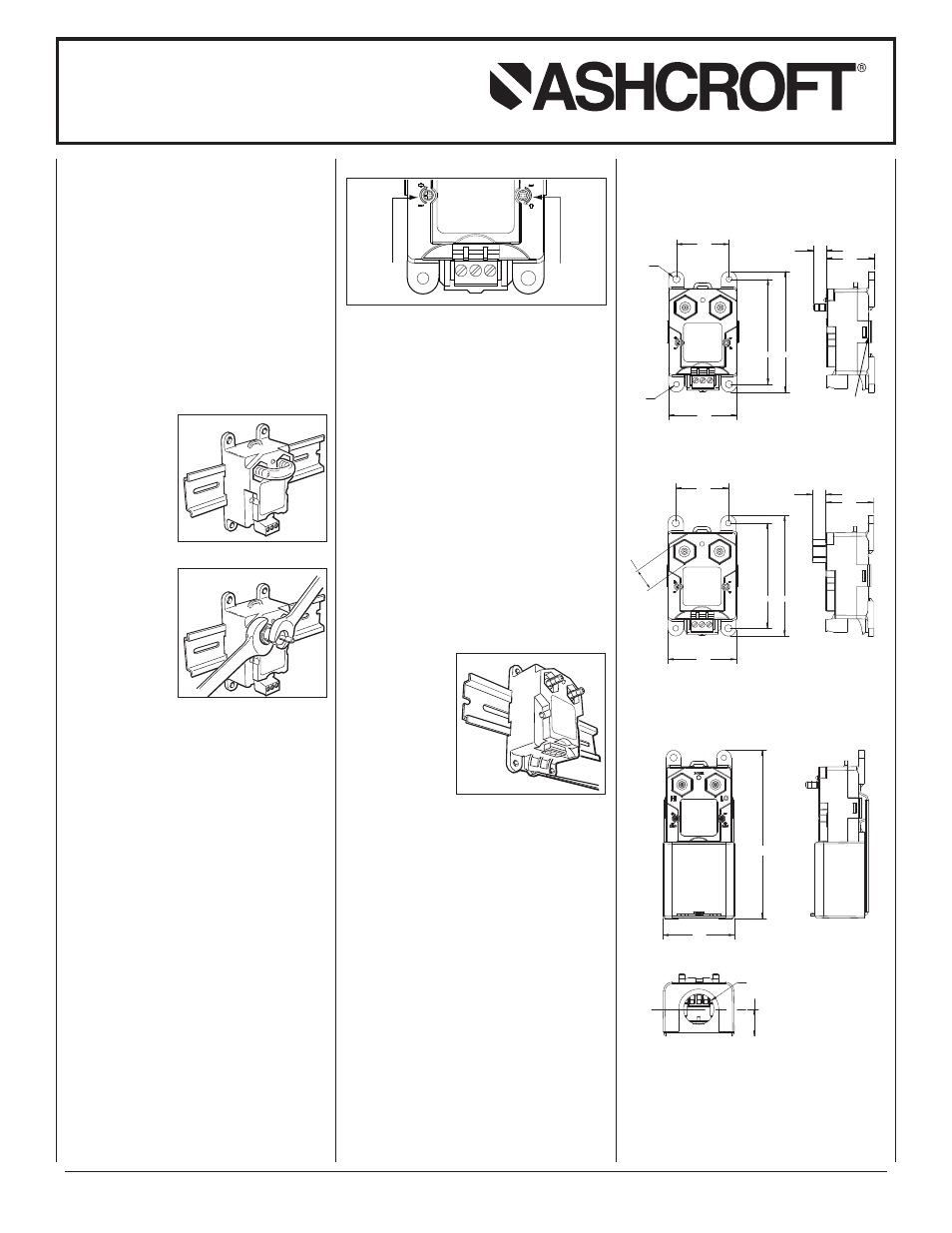

"B2" 1/4 BARB FITTINGS

1.32

.37

POWER

HI

LO

SPAN

ZERO

HOUSING TABS (2)

1.45

2.90

3.33

1.89

"01" 1/8 FEMALE NPT FITTINGS

1.32

.37

POWER

HI

LO

SPAN

ZERO

.56

MB2

1

⁄

4

˝ BARB FITTINGS

F01

1

⁄

8

NPT FEMALE FITTINGS

GENERAL DIMENSIONS FOR

MODEL CXLdp (in inches)

4.85

4.85

2.06

2.06

ASSEMBLED WITH 101A213-01 CONDUIT KIT

.78

.78

R

R .88

.88

ASSEMBLED WITH 101A213-01

CONDUIT KIT

4. Firmly reinstall the terminal block plug to its

mating connector.

Set Up:

Note: For best immunity from EMI the pressure

connection fittings on the CXLdp should not be

grounded.

The transmitters are calibrated at the factory in the

vertical position. Mounting in the horizontal posi-

tion can cause a zero shift of as much as ±1% F.S.

in ranges below 1 IW dp. Any minor zero offset can

be minimized using the zero adjust potentiometer

located on the front, left side of the instrument.

To find true zero differential pressure, pneumati-

cally connect the high and low pressure connec-

tions together using the tubing provided with the

transmitter. The

barbed connection

accept

1

⁄

4

˝ O.D.

1

⁄

8

˝

I.D. tubing.

(see Figure 5)

When

1

⁄

8

NPT fe-

male brass fittings

are used, do not

exceed 60 inch-

pound torque force

on female NPT fit-

ting.

When connecting to

the NPT fittings, do

not apply torque to

the CXLdp fitting.

Use a

9

⁄

16

˝ wrench to

hold the CXLdp.

(see Figure 6)

Zero potentiometer adjustment requires using a

3

⁄

32

˝

or 2.5 mm slotted or phillips screwdriver. The tub-

ing should remain in place until the transmitter is

to be connected to the BCS tubing system.

(see Figure 7)

Figure 5

Figure 6

Routine Maintenance:

The CXLdp is a very stable and reliable transmitter

incorporating a proven, micro-machined silicon ca-

pacitive sensor and a new, state-of-the-art applica-

tion specific integrated circuit (ASIC).

All calibration and temperature compensation func-

tions are done with a microprocessor and

digital routines.

To troubleshoot or verify performance, it is recom-

mended to pneumatically connect the pressure

ports to each other and establish a zero offset

reading in the as-installed position. Adjusting zero

will not affect span calibration.

Adjusting span should only be attempted when a

high accuracy pressure standard and high quality

electrical meter are able to be used.

DIN Rail Transmitter Removal:

In order to remove the transmitter when it is installed

on a DIN rail, it is necessary to first unplug the wiring

terminal block from the transmitter.

Insert a small slot-

ted screwdriver into

the black plastic

clip extending

slightly below the

transmitter case.

(see Figure 8)

Next, raise the

screwdriver handle

up thereby forcing

the spring clip down.

If questions or concerns need to be addressed, our

Low Pressure Product Manager or Engineering

Personnel can be contacted at (203) 378-8281 or

visit our website at www.ashcroft.com.

Figure 8

Figure 7

SPAN

ZERO

Zero adjust

potentiometer

Span adjust

potentiometer

Zero and Span Potentiometers

© 2011 Ashcroft Inc. 250 East Main Street 06614, Tel: 203-378-8281 • Fax: 203-378-0499, All specifications are subject to change without notice.

All sales subject to standard terms and conditions. www.ashcroft.com All rights reserved. I&M011-10130 Rev. A 10/12