Aalborg DFM Digital User Manual

Page 32

Analog output signals of 0-5 Vdc, (0-10 Vdc optional) or 4-20 mA are attained at

the appropriate pins of the 25-pin "D" connector (see Figure b-1) on the side of the

DFM transducer.

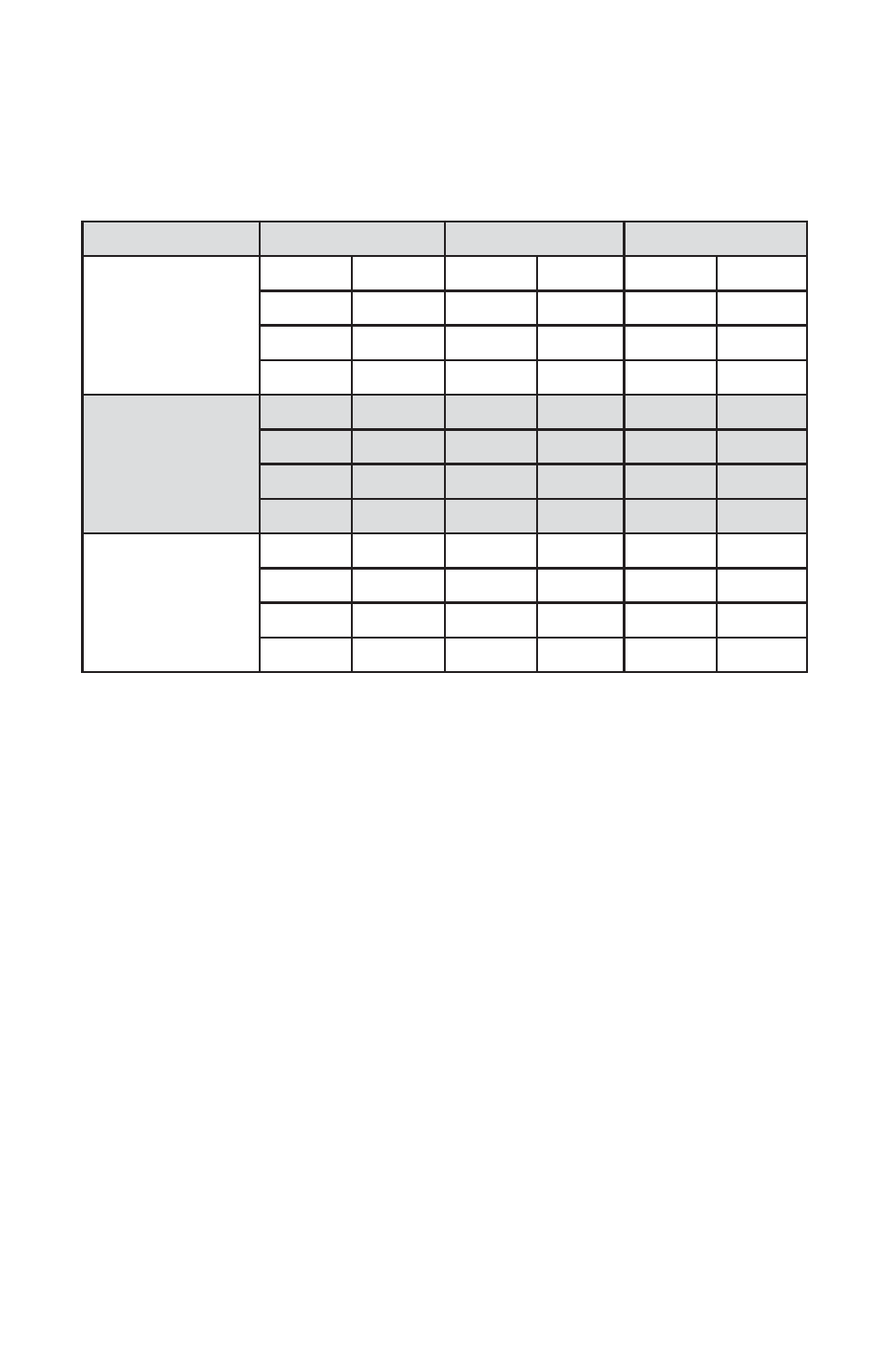

Table VI Analog Output Jumper Configuration

See APPENDIX IV for actual jumpers layout on the analog PCB.

6. MAINTENANCE

6.1 Introduction

It is important that the Mass Flow Meter is used with clean, filtered gases only.

Liquids may not be metered. Since the RTD sensor consists, in part, of a small

capillary stainless steel tube, it is prone to occlusion due to impediments or gas

crystallization. Other flow passages are also easily obstructed. Therefore, great

care must be exercised to avoid the introduction of any potential flow impediment.

To protect the instrument a 50 micron (DFM26/27) or 60 micron

(DFM 36/46/37/47) filter is built into the inlet of the flow transducer. The filter

screen and the flow paths may require occasional cleaning as described below.

There is no other recommended maintenance required. It is good practice, how-

ever, to keep the meter away from vibration, hot or corrosive environments and

excessive RF or magnetic interference. If periodic calibrations are required they

should be performed by qualified personnel and calibrating instruments, as

described in section 7. It is recommended that units are returned to Aalborg

7 for

repair service and calibration.

28

ANALOG SIGNAL

0-5 VDC

0-10 VDC

4-20 mA

Flow Rate Output

Jumper Header J2

J2.A

5-9

J2.A

5-9

J2.A

1-5

J2.B

2-6

J2.B

2-6

J2.B

2-6

J2.C

7-11

J2.C

7-11

J2.C

3-7

J2.D

8-12

J2.D

8-12

J2.D

4-8

Temperature Output

Jumper Header J3

J3.A

5-9

J3.A

5-9

J3.A

1-5

J3.B

2-6

J3.B

2-6

J3.B

2-6

J3.C

7-11

J3.C

7-11

J3.C

3-7

J3.D

8-12

J3.D

8-12

J3.D

4-8

Pressure Output

Jumper Header J4

J4.A

5-9

J4.A

5-9

J4.A

1-5

J4.B

2-6

J4.B

2-6

J4.B

2-6

J4.C

7-11

J4.C

7-11

J4.C

3-7

J4.D

8-12

J4.D

8-12

J4.D

4-8