Iv combustion chamber continued – Midco Unipower A-Series User Manual

Page 4

■

■

■

■

For warm-air furnaces or Scotch Marine boilers with tubular combustion chambers, the

combustion chamber length must be great enough to exceed the lengths given in Table 2 by at

least 20%.

■

■

■

■

Combustion chamber proportions may be changed if necessary to avoid flame impingement on

critical parts such as drop sections in cast iron boilers or the heat exchanger surfaces of a warm-

air furnace. If sustained flame contact cannot be avoided, protect the surfaces with 2

1

/

2

" or

firebrick.

■

■

■

■

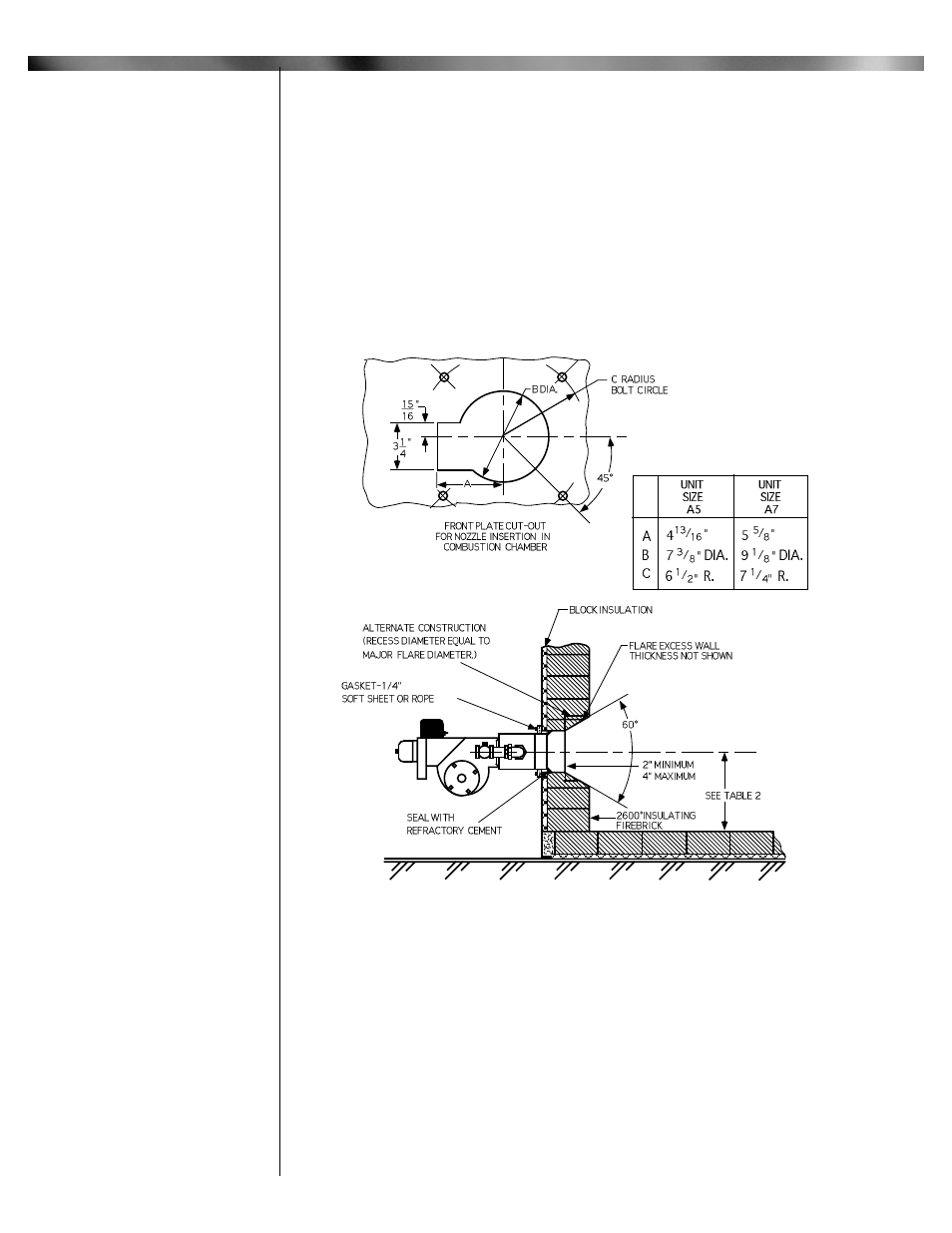

The burner nozzle must not extend into the combustion chamber. It should be sealed into the

opening as shown in Figure 4. The burner mounting to the appliance front must be rigid and

sealed with

1

/

4

" soft refractory sheet or rope. See Figure 5 for mounting flange dimensions.

■

■

■

■

Allow a space of about 1" between the edges of the floor brickwork and the appliance base to

allow for expansion and creep. Where wall construction is such that both ends butt against rigid

appliance parts such as the base of a water leg, allow

1

/

4

" space between bricks every four feet

or so for expansion joints, particularly when reduced size combustion chambers are used.

Firing Door Installations

■

■

■

■

Greater care in planning will be required for firing door applications since flame impingement

on heat exchange surfaces is more probable. Do not fire a boiler containing a drop section

directly in the path of the flame, or over the water grate in a smokeless type boiler. The firebox

length must be great enough to exceed the combustion chamber lengths given in Table 2 by at

least 20%.

■

■

■

■

When raising the floor, maintain sufficient firebox volume to limit the heat release per cubic

foot to 50 MBH or less. Use the entire floor as a combustion chamber and cover any water leg

base to 6" from the bottom to avoid firing areas filled with sediment. Floor construction should

conform to Figures 1, 2 or 3.

■

■

■

■

The burner mounting in the door must be rigid and refractory lined as shown in Figure 9. The

burner nozzle must not protrude directly into the combustion chamber. The refractory liner must

be flush with or extend beyond the burner face as shown in Figure 4. A sheet metal rim should

encase the refractory up to the inside of the boiler wall. It should be intermittently bent inward to

retain the refractory or other means of anchoring should be provided. A refractory felt blanket

can be used in lieu of castable refractory, which will simplify construction at the burner entry.

IV Combustion Chamber

Continued

C

L

Figure 4: Construction at Burner Entrance

4